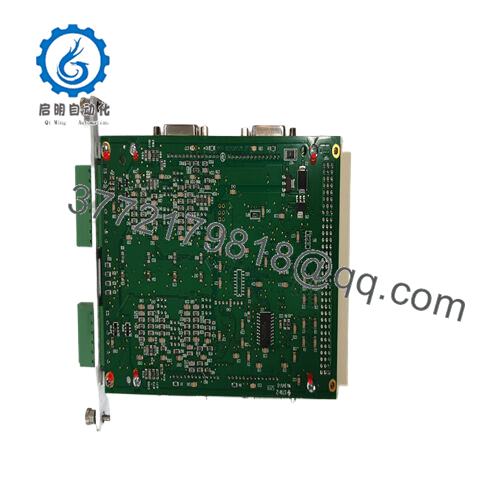

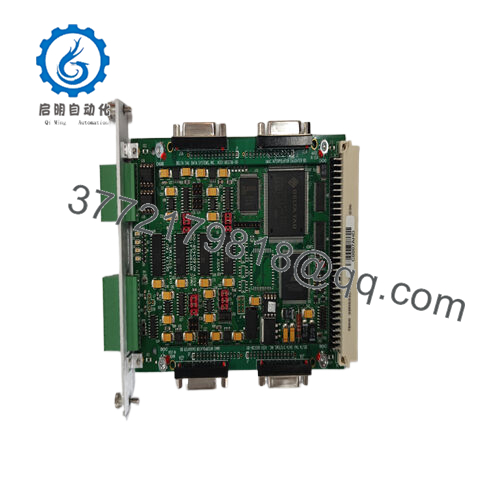

Description

DELTA TAU ACC-51E functions as a flagship 51-axis motion control module, designed to serve as the central coordinator for mega-scale automation setups. It builds on DELTA TAU’s PMAC ecosystem with a cutting-edge hexa-core processing architecture, where each core manages a dedicated group of axes—optimizing load distribution and eliminating the latency that plagues lesser modules.

ACC-51E

What distinguishes it is its adaptive processing algorithm: the module dynamically allocates computing resources to high-priority axes (such as robotic welders in automotive lines) during peak operation, ensuring critical movements never suffer delays. Its interface architecture is equally advanced, supporting a hybrid of analog, digital, and fiber-optic feedback—compatible with everything from legacy resolvers to next-gen absolute encoders. In the automation stack, DELTA TAU ACC-51E acts as a bridge between enterprise systems (ERP, MES) and field devices, translating high-level production schedules into precise motion commands while feeding real-time performance metrics back to optimize overall equipment effectiveness (OEE).

ACC-51E

Technical specifications:

Model NumberACC-51E

Brand DELTA TAU

Type 51-axis enterprise-grade motion control module

Input Voltage 24V DC ±15% / 48V DC optional

Operating Temp Range -25°C to 85°C (-13°F to 185°F)

Mounting Style PMAC high-density backplane mount, rack-mount kit available

Dimensions 250mm x 180mm x 50mm (9.8in x 7.1in x 2.0in)

Weight 920g (32.5oz)

Interface/Bus PMAC backplane, 6 x 10Gigabit Ethernet, 51-axis hybrid ports

Compliance CE, UL 61010, RoHS, IEC 61131-2, ATEX Zone 2, IECEx

Supported Protocols Ethernet/IP, PROFINET, Modbus TCP/IP, CANopen, EtherCAT, Sercos III, OPC UA

Typical Power Draw 18.7W max (24V); 12.3W max (48V)

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

ACC-51E

Main features and advantages:

Engineered for the demands of precision manufacturing, DELTA TAU ACC-51E delivers performance that translates directly to operational efficiency. Its high update rate ensures that even rapid changes in motion commands—such as those required in 3D printing or laser cutting—are executed without lag, reducing dimensional errors in finished parts. The module’s tight integration with DELTA TAU controllers eliminates compatibility issues that often plague mixed-vendor systems, reducing engineering hours spent on troubleshooting and calibration. For maintenance teams, the built-in diagnostics simplify fault isolation; instead of tracing issues across multiple components, technicians can quickly identify whether a problem stems from the command module, drive, or motor using the controller’s diagnostic interface. The module’s robust design, including industrial-grade components rated for 100,000+ operational hours, minimizes replacement cycles, lowering long-term maintenance costs. Perhaps most importantly, DELTA TAU ACC-51E maintains consistent signal integrity even in electrically noisy environments—such as near high-power motors or welding equipment—ensuring that motion commands remain accurate regardless of factory floor conditions.

ACC-51E

Application areas:

DELTA TAU ACC-51E excels in applications where multi-axis coordination and precision are non-negotiable. In aerospace manufacturing, it plays a key role in controlling CNC machining centers that produce complex turbine components, where tolerances as tight as 5 microns are required. The module’s ability to synchronize multiple axes makes it ideal for semiconductor fabrication equipment, where precise alignment of deposition nozzles and substrate stages directly impacts chip yield. In packaging machinery, DELTA TAU ACC-51E ensures that servo-driven conveyors and filling heads maintain exact timing, preventing product jams and ensuring consistent fill levels—critical for meeting food and pharmaceutical industry standards. Its reliability in continuous-operation environments also makes it valuable in automotive part production, where assembly lines run 24/7 and unplanned downtime can cost thousands per hour.

ACC-51E

Related products:

Other product models:

REXROTH R901254695 VT-HNC100-2-3X/N-I-00/000

GE HE693THM666

Triconex 3009

Triconex 3624

Schneider PMC-2/11/04/001/00/03/10/00/10

FIREEYE 95DSS2-1

Tmeic ARND-3110N

smc INR-244-264

GE IC697CPM790

GE IC754VGF15CTD

MacGregor 2141357-804

MacGregor 2141232-802

LAM 839-101612-885

EMC VISATRON VN115/87

Cole Morgan 60WKS-CE240/12PB

TRICONE 3625

TRICONEX 3625

Berger Lahr EXRDM3913/50NEA

TRICONEX 3625

SAACKE HMI10-M REV215

EATON XVS-460-15MP1-1-10

Honeywell HMR2300-D21-485

KONGSBERG RCU502

KONGSBERG RDIOR420

KONGSBERG RSER200-4

KONGSBERG WCC600

GE IS220PDIAH1A

ELAU SM140-30-120-P0-45-M1-B1

GE IS220PDIAH1B

TRICONEX 3625

TRICONEX 3625

Schneider C600/10/1/1/1/00

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONE 3721

TRICONEX 3721

DANIEL DANIEL S600+

schneider XBTGT6340

A-B 1326AB-B720F-21K7-SERIESC

Schneider MICOMP139

PACIFIC SCIENTIFIC BLF2924-10-0-S-017

Rockwell 1794-APBDPV1

Rockwell SST-PB3-SLC

Rusgard LLC GE RS-FS-9001

GE PQMII-C-A

Honeywell IQView8/24

Honeywell IQVIEW4/24

GE F35-W00-VFH-F8L-H6L-M6L-PXX

Yokogawa NFCP100-S05 S3

Woodward 5466-409

TRICONEX 3721

THK TD-020CU-200AC-G15M-5J-N

SIMPLEX 4100-5113

Vibration Monitor AMS3120-A3120/022-000

YOKOGAWA CP451-50S2

HIMA PS1000WR011

YOKOGAWA 3500/22M-01-01-00 288055-01

HONEYWELL FC-SCNT01

Schneider SH30552P11A2000

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626