Description

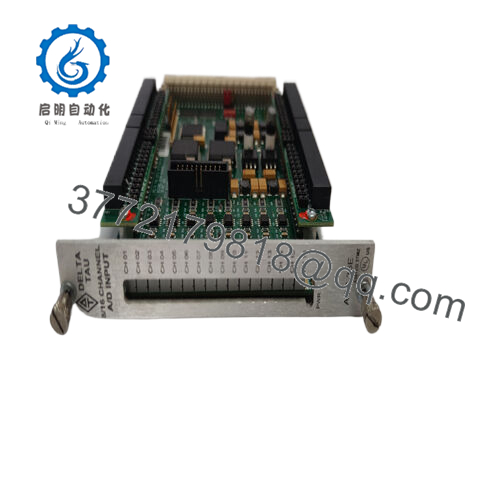

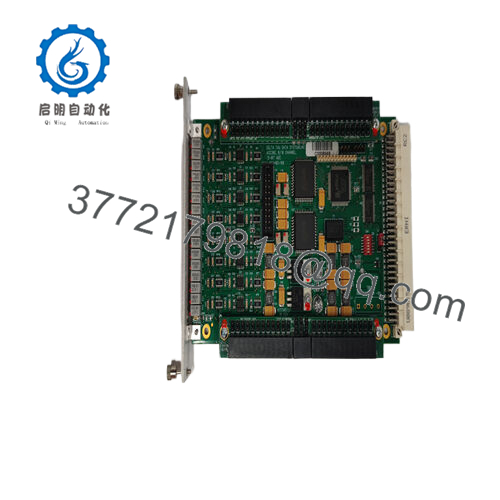

- Product Model: ACC-36E

- Product Brand: Delta Tau

- Product Series: ACC (Accessory) family for UMAC / Turbo

- Product Features:

• 16-channel 12-bit A/D converter with ±10 V input range

• Rack-mounted 3U card that connects via the UMAC / Turbo backplane

• DIP switch / jumper config for addressing and multiplexing

• Supports multiplexed conversion, phase clock control for timing optimization

- ACC-36E

Applications & Industry Context

In automation or motion control systems, having analog feedback or sensor inputs is often essential. The ACC-36E is designed exactly for that role: capturing multiple analog signals (up to 16 channels) at moderate resolution (12 bits) under the UMAC / Turbo architecture.

You’ll often see ACC-36E used for reading analog sensors such as thermocouples (with appropriate front-end), strain gauges, position feedback signals (±10 V transducers), force sensors, or other process instrumentation signals. Because the module interfaces directly into the backplane of a UMAC or Turbo system, it enables tight integration of analog signals into motion logic without external wiring back to a PLC or separate data acquisition system.

For example, in a machine tool, you might use ACC-36E to monitor spindle vibration, temperature, or coolant flow analog sensors and feed that data into the motion controller for adaptive control or protection. In a semiconductor tool, you might read analog humidity sensors, pressure sensors, or process monitors. In test benches or lab automation systems, such a module provides dense analog capture close to the controller, reducing wiring noise and simplifying architecture.

One field insight: when upgrading legacy systems, the ACC-36E lets integrators retire standalone analog I/O racks and fold their analog signals into the motion controller environment — reducing wiring, latency, and synchronization drift.

Because many motion systems require periodic sampling synchronized with servo cycles, the ACC-36E’s ability to multiplex and sync with phase clocks helps ensure the analog data is aligned with motion events.

Product Role & System Fit

The ACC-36E is an accessory (ACC) module that resides in the expansion rack of a UMAC or Turbo controller environment. It does not execute motion trajectories or manage servo loops; rather it functions as a front-end analog input module, converting external sensor voltages into digital data accessible by the controller.

In the UMAC / Turbo context, ACC-36E interfaces through the backplane (UBUS or equivalent expansion bus). The controller logic (in UMAC) addresses the ACC-36E’s memory map, triggering conversions, reading channel results, and using them in decision logic, closed-loop adjustments, or supervisory monitoring.

Because the ACC-36E is modular, multiple such cards can coexist in the same system, scaling analog input capacity without external I/O multiplexers. It pairs with other ACC boards (digital I/O, encoder interface, servo interface, fieldbus gateway) to build a full motion system.

From the system integrator’s perspective, ACC-36E becomes the analog front end tightly synchronized with motion events, improving determinism and reducing analog cable length or external ADC delays.

Technical Features & Benefits

The ACC-36E offers several practical features that make it well suited for embedded motion-control applications:

- 16-Channel 12-Bit A/D Conversion, ±10 V Range

The module supports up to 16 analog channels, each converting to 12-bit resolution with input range ±10 V. This level of resolution is often adequate for many motion or process sensor signals without overburdening the controller bandwidth. - 3U Rack / Card Form Factor

The module fits within a standard 3U expansion rack, occupying a slot in the UMAC / Turbo system architecture. This compact footprint facilitates high channel density in control cabinets. - Multiplexing & Phase-Clock Control

To conserve internal resources, the ACC-36E multiplexes analog channels. Also, the hardware phase clock period is configurable (via jumpers) and in some variants controlled by variables (I7000, I7001 etc.), letting you align A/D sampling with servo cycles or adjust timing tradeoffs. - Jumper / DIP Configuration

The board includes DIP switches or jumpers for address, mode selection, sampling timing, and multiplexing configuration. This allows on-site flexibility without firmware changes. - Automatic Data Transfer / Backplane Integration

The ACC-36E is built to support automatic data transfers between its channels and the UMAC memory space — which simplifies driver code and reduces polling overhead. - Synchronization with Motion Logic

Because motion controllers often run in periodic loops, the ACC-36E can be synchronized (via phase clock settings) to sample analog inputs at consistent points in the servo cycle. This yields more meaningful, time-aligned analog data for control decisions. - Robust Integration & Legacy Support

Many systems still use analog sensors. ACC-36E offers a bridge between analog world and motion logic without needing external DAQ systems or PLC analog modules, thus simplifying system architecture.

In practice, implementing ACC-36E yields lower latency analog inputs, reduced wiring, more deterministic sampling, and closer coupling of analog data to motion control loops.

Technical Specifications Table

Here’s a summary of the known technical specs of ACC-36E:

| Specification | Value / Description |

|---|---|

| Model | ACC-36E |

| Function | 16-channel analog (A/D) input module |

| Resolution | 12 bits per channel |

| Input Range | ±10 V (typical) |

| Rack / Format | 3U expansion card in UMAC / Turbo expansion rack |

| Backplane Interface | UMAC / Turbo expansion bus (backplane memory mapping) |

| Multiplexing | Channels multiplexed internally for conversion |

| Phase Clock / Timing Control | Configurable via jumpers E98, E29–E33; variables I7000 / I7001 etc. |

| Address / Mode Config | DIP switches / jumpers for addressing and mode setup |

| Operating Environment | Control cabinet / RACK environment |

| Weight / Dimensions | Standard card dimensions (3U) (exact weight depends on variant) |

| Integration | Automatic data transfer support with UMAC logic modules |

Installation & Maintenance Insights

From experience and reference materials, here are some useful practices when deploying the ACC-36E in a system:

- Slot Insertion & Backplane Integrity

Always power down the expansion rack before inserting or removing the ACC-36E. Ensure alignment in the expansion slot to avoid bent pins or backplane damage. - Jumper / Switch Setup Prior to Power-Up

Before energizing, set the DIP switches or jumpers for board address, phase-clock mode, multiplex scheme, and the I7 (phase divider) value if using variables. Incorrect jumper settings may lead to mapping conflicts or sampling misalignment. - Cable Routing & Signal Integrity

Analog signal cables should be shielded and routed away from high-current motor cables or switching circuits. Ground shields appropriately (usually at one end) to avoid ground loops. - Sampling Timing Coordination

If your motion logic demands that analog inputs are sampled at specific points in the servo cycle, use the phase clock configuration options to align A/D conversion with motion events. For example, you may set I7 > 0 so that the software phase update cycles align with hardware phase clock cycles as needed. - Incremental Commissioning

When first powered, verify that each channel is accessible via UMAC memory mapping. Test each channel with known input voltages (e.g. 0 V, +5 V, –5 V, ±10 V) before enabling it in control logic. This helps catch wiring or conversion errors early. - Temperature & Ventilation

Ensure the control cabinet maintains moderate temperature; analog modules can drift if exposed to heat. Avoid stacking modules so that airflow is obstructed around ACC-36E. - Routine Inspection & Reseating

On a scheduled basis (e.g. annually), power down and reseat the ACC-36E to ensure connector integrity under vibration. Inspect solder joints, jumpers, and connectors for corrosion or looseness. - Backup Configuration

Document your jumper and DIP settings, and keep a copy of any configuration variables (e.g. I7000, I7001) so that in case of replacement you can restore identically. - Diagnostics & Error Handling

Use UMAC’s diagnostic tools or logs to detect any anomalous ADC values (e.g. out-of-range, saturating readings, noise). If issues appear, check ground referencing, analog front-end wiring, and power supply ripple.

In the field, a common source of analog errors is ground reference shift: make sure sensor reference grounds and drive system grounds are managed carefully. Also, when multiplexing many channels, avoid having high-frequency switching signals on adjacent channels unless properly filtered.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626