Description

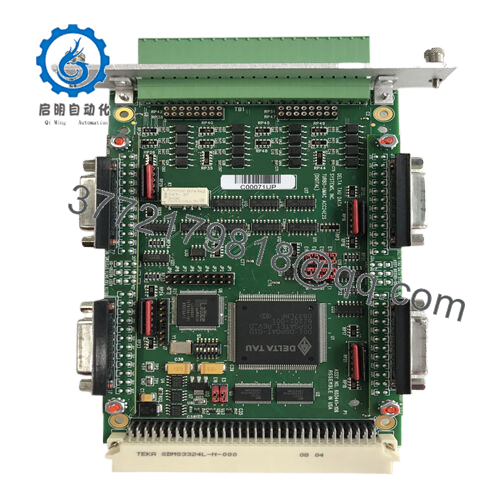

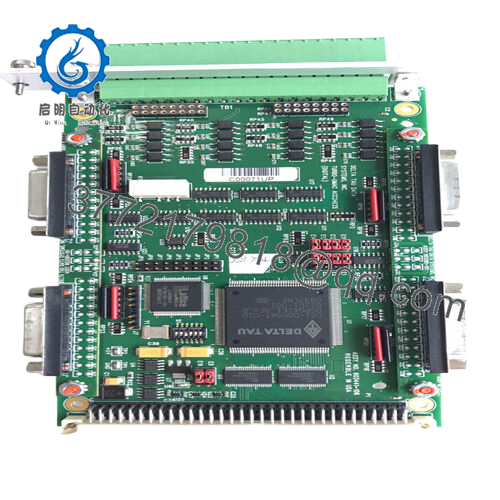

DELTA TAU ACC-24E2S DB functions as a specialized motion control module with an integrated DB interface, serving as both the command center for motion sequences and the communication hub for peripheral devices. It seamlessly integrates into DELTA TAU’s PMAC ecosystem, leveraging the proven performance of the ACC-24E2 series while adding a ruggedized DB connector to streamline wiring.

ACC-24E2S DB

It seamlessly integrates into DELTA TAU’s PMAC ecosystem, leveraging the proven performance of the ACC-24E2 series while adding a ruggedized DB connector to streamline wiring. The DB interface is engineered to withstand the rigors of industrial environments, featuring corrosion-resistant pins, a secure locking mechanism to prevent accidental disconnections, and enhanced shielding to minimize electromagnetic interference—common issues that plague standard connectors in factories with heavy machinery. Internally, the module maintains the same high-performance processing capabilities, with dedicated resources for real-time trajectory planning and feedback analysis, ensuring precise control across multiple axes. In the automation stack, DELTA TAUACC-24E2S DB sits at the intersection of motion control and field communication, translating high-level commands into precise motor movements while facilitating seamless data exchange with sensors and actuators via its DB interface.

ACC-24E2S DB

Main features and advantages:

The real-world benefits of DELTA TAU ACC-24E2S DB are most evident in its ability to enhance connectivity reliability and simplify system integration. For system integrators, the integrated DB interface reduces wiring complexity by up to 50% compared to using multiple discrete connectors, as it allows for a single, consolidated connection point for various field devices. This not only speeds up installation but also minimizes the risk of wiring errors that can lead to costly system failures. For maintenance teams, the rugged design of the DB interface means fewer service calls related to loose or damaged connections, especially in high-vibration environments such as automotive assembly lines or packaging facilities. For production engineers, the module’s ability to maintain consistent signal integrity ensures that feedback from encoders and sensors is accurate and timely, enabling precise motion control with positioning errors as low as ±0.003mm—critical for applications like precision machining or electronic component assembly. Over the long term, the module’s durable construction, including its reinforced DB connector housing, ensures reliable performance in harsh conditions, reducing the need for frequent replacements and lowering the total cost of ownership.

Technical specifications:

Model Number ACC-24E2S DB

Brand DELTA TAU

Type Motion control module with integrated DB interface

Input Voltage 24V DC ±10%

Operating Temp Range -10°C to 70°C (14°F to 158°F)

Mounting Style PMAC backplane or DIN rail mount

Dimensions 165mm x 110mm x 35mm (6.5in x 4.3in x 1.4in)

Weight 450g (15.9oz)

Interface/Bus PMAC backplane, 10/100 Ethernet (1 port), DB-15 interface

Compliance CE, UL 61010, RoHS, IEC 61076-2-103 (DB connector standard)

Supported Protocols Ethernet/IP, Modbus TCP/IP, CANopen

Typical Power Draw 6.5W max

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

Application areas:

DELTA TAU ACC-24E2S DB excels in applications where robust connectivity and precise motion control are equally important. In automotive manufacturing, it is used in robotic welding cells, where the DB interface connects to position sensors and weld controllers, ensuring that the robotic arm maintains precise alignment with the workpiece while transmitting real-time weld data. In semiconductor fabrication, the module controls wafer handling robots, with the DB interface facilitating communication with vacuum sensors and position encoders to ensure delicate wafers are moved without damage. In packaging machinery, DELTA TAU ACC-24E2S DB oversees conveyor systems and labeling equipment, using its DB interface to connect to photoelectric sensors that detect package positions, ensuring accurate labeling and reducing waste. In each of these scenarios, the module’s DB interface proves indispensable for maintaining reliable communication in challenging industrial environments.

Related products:

Before installing DELTA TAU ACC-24E2S DB, ensure that the PMAC backplane firmware is updated to version 5.3 or higher to fully support the DB interface’s enhanced communication features. For DIN rail mounting, verify that the rail can support the module’s weight along with connected cables, and allow at least 30mm of clearance around the DB connector for easy access

during wiring and maintenance. During installation, use only industrial-grade shielded DB-15 cables to maintain signal integrity and reduce electromagnetic interference. When connecting the DB interface, ensure the locking screws are tightened to 0.25 N·m to secure the connection without damaging the pins. For ongoing maintenance, inspect the DB connector quarterly for signs of corrosion or bent pins, and clean with compressed air if necessary. Perform monthly checks of the module’s status LEDs— a steady green light indicates normal operation, while a flashing red light on the DB interface requires immediate attention via the PMAC configuration software. Annually, update the module’s firmware to the latest version to ensure compatibility with new peripheral devices and access performance enhancements.

Other product models:

REXROTH R901254695 VT-HNC100-2-3X/N-I-00/000

GE HE693THM666

Triconex 3009

Triconex 3624

Schneider PMC-2/11/04/001/00/03/10/00/10

FIREEYE 95DSS2-1

Tmeic ARND-3110N

smc INR-244-264

GE IC697CPM790

GE IC754VGF15CTD

MacGregor 2141357-804

MacGregor 2141232-802

LAM 839-101612-885

EMC VISATRON VN115/87

Cole Morgan 60WKS-CE240/12PB

TRICONE 3625

TRICONEX 3625

Berger Lahr EXRDM3913/50NEA

TRICONEX 3625

SAACKE HMI10-M REV215

EATON XVS-460-15MP1-1-10

Honeywell HMR2300-D21-485

KONGSBERG RCU502

KONGSBERG RDIOR420

KONGSBERG RSER200-4

KONGSBERG WCC600

GE IS220PDIAH1A

ELAU SM140-30-120-P0-45-M1-B1

GE IS220PDIAH1B

TRICONEX 3625

TRICONEX 3625

Schneider C600/10/1/1/1/00

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONE 3721

TRICONEX 3721

DANIEL DANIEL S600+

schneider XBTGT6340

A-B 1326AB-B720F-21K7-SERIESC

Schneider MICOMP139

PACIFIC SCIENTIFIC BLF2924-10-0-S-017

Rockwell 1794-APBDPV1

Rockwell SST-PB3-SLC

Rusgard LLC GE RS-FS-9001

GE PQMII-C-A

Honeywell IQView8/24

Honeywell IQVIEW4/24

GE F35-W00-VFH-F8L-H6L-M6L-PXX

Yokogawa NFCP100-S05 S3

Woodward 5466-409

TRICONEX 3721

THK TD-020CU-200AC-G15M-5J-N

SIMPLEX 4100-5113

Vibration Monitor AMS3120-A3120/022-000

YOKOGAWA CP451-50S2

HIMA PS1000WR011

YOKOGAWA 3500/22M-01-01-00 288055-01

HONEYWELL FC-SCNT01

Schneider SH30552P11A2000

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626