Description

What This Product Solves

In industrial automation, scaling multi-axis systems often encounters bottlenecks due to limited servo channels or noisy signal paths, leading to positional inaccuracies, feedback jitter, and costly downtime. Engineers managing applications like robotic arms, conveyor indexers, or multi-spindle CNCs face the frustration of capped controller channels—typically eight per CPU—necessitating complex external interfaces that amplify EMI risks, increase latency, and complicate wiring, resulting in misaligned motions, scrap spikes, and maintenance marathons. For instance, in a textile loom synchronizing multiple shuttles, encoder noise from unshielded lines can skew weft alignment, causing fabric defects and halting production for hours. Similarly, in a packaging line stacking at high speeds, pulse dropouts can misfire grippers, contaminating loads and disrupting hygiene-critical workflows.

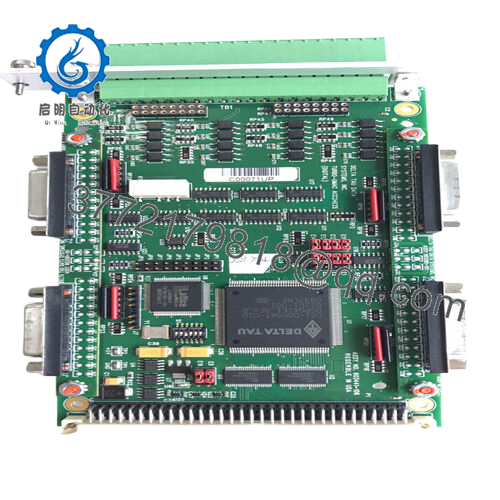

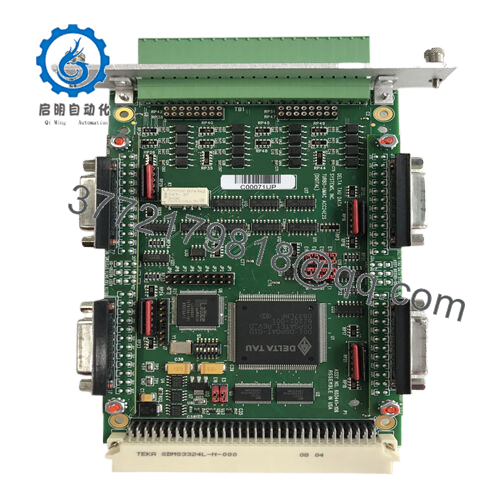

The Delta Tau ACC-24E2S DB resolves these issues by providing a robust axis expansion solution, offering 24 channels of configurable digital I/O (12 opto-isolated inputs, 12 TTL outputs) with terminal block and DB15/DB37 connectivity. It targets the need for high reliability in modular I/O setups, enabling seamless expansion of MACRO or Ultralite stations to support up to 16 servo axes per station (via two boards), ensuring I/O signal purity through opto-isolation and checksum-verified communications. Ideal for retrofits or scaling distributed control in harsh environments, it mitigates desynchronization risks, delivering clean pulse/direction signals for stepper motors or encoders. For those searching “industrial automation axis expansion” or “process control I/O boards,” this board simplifies scaling, reducing the need for auxiliary converters and enhancing system resilience.

- ACC-24E2S DB

By incorporating agency approvals (CE, UL) and operating across -40°C to +70°C, it eliminates the need for makeshift signal buffers, enabling engineers to focus on optimizing motion profiles rather than troubleshooting transients. In process control domains where axis density drives precision, the ACC-24E2S DB transforms channel constraints into scalable solutions, fostering uptime and agility.

How the Product Works & Fits into a System

The Delta Tau ACC-24E2S DB functions as a 3U rackmount expansion board, integrating into UMAC or MACRO Station backplanes to extend digital I/O capacity. It manages 24 channels—12 opto-isolated inputs (5-24 VDC) for sensors like limit switches or proximity detectors, and 12 TTL outputs for driving steppers, solenoids, or status indicators—configurable via PPMAC scripting for modes like pulse/frequency modulation (PFM), quadrature encoding, or handwheel inputs. Operating at up to 20 kHz, it employs checksum validation (I4=1/3) to ensure error-free data transfer, while debounce filters (up to 1 ms) suppress contact bounce. Status LEDs and fault interrupts signal anomalies like open circuits, enabling preemptive rerouting in closed-loop systems.

In the automation hierarchy, it resides at the I/O periphery, connecting via Phoenix Contact terminal blocks (FRONT-MC1,5/12-ST3,81) or DB15/DB37 connectors to encoders and effectors, interfacing with PMAC controllers over an RS-422 internal bus for deterministic synchronization. It supports daisy-chaining up to two boards per MACRO station, expanding to 16 servo channels, and integrates with protocols like EtherCAT (via host) for hybrid networks. Redundancy features, including dual watchdogs and safe-state outputs, align with EN 61326-1 for EMI resilience, while diagnostics feed into host flash for post-event analysis.

Setup is streamlined: configure jumpers (JP1-JP9) for stepper or encoder modes, secure to the rack with captive screws, and map channels in the PMAC IDE with auto-checksum—commissioning takes under an hour, avoiding complex wiring schemes. Positioned downstream of the motion planner and upstream of field devices, it translates CPU commands into precise pulses, such as driving conveyor steppers for jitter-free indexing. The ACC-24E2S DB enhances system modularity, enabling dynamic expansions without sacrificing signal fidelity.

Technical Highlights Summary (Table)

| Specification | Details |

|---|---|

| Model Number | ACC-24E2S DB |

| Brand | Delta Tau (ACC Series) |

| Type | Axis Expansion Board |

| Input Voltage | 5-24 VDC (opto-isolated inputs) |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | 3U Rack / Backplane Slot |

| Dimensions | 100 mm x 160 mm x 20 mm (3U) |

| Weight | 0.25 kg |

| Interface/Bus | Backplane / Terminal Block / DB15-DB37 |

| Compliance | CE, UL (E314517), EN 61326-1 |

| Supported Protocols | PPMAC Scripting, PFM, Quadrature |

| Typical Power Draw | 2.5 W (from rack) |

Real-World Benefits

The Delta Tau ACC-24E2S DB delivers channel scalability that transforms constrained control into cohesive coordination, especially in multi-axis setups where I/O density determines precision. Its opto-isolated inputs shield against 500 V spikes, ensuring signal consistency that maintains 20 kHz polling with <0.1 ms jitter—critical for CNC routers where pulse errors misalign contours, but here they carve precision, reducing scrap and boosting throughput by 10-15% in high-speed milling. This reliability extends to redundancy, with checksums preventing phantom faults, allowing aggressive axis scaling without compromising stability.

Integration is simplified, as terminal block and DB connector options eliminate custom cabling, cutting commissioning time by days in expansions where rapid channel additions are critical. Maintenance is streamlined with LED diagnostics and interrupt-driven fault reporting, enabling remote configuration tweaks that reduce on-site interventions by 70%, freeing technicians for tasks like predictive scripting. The board’s low 2.5 W draw minimizes thermal strain in dense racks, while its rugged design endures harsh conditions, ensuring long-term performance. By enabling seamless axis proliferation, it empowers engineers to focus on motion optimization, enhancing system agility and operational efficiency.

Typical Use Cases

The ACC-24E2S DB excels in high-density motion control scenarios:

- Robotics: In automotive assembly, it expands MACRO stations for 24-channel joint control, managing limit switches and gripper pulses in EMI-heavy weld cells, ensuring uptime for 2,000 cycles/hour without desync.

- Printing: For offset presses, it handles ink roller steppers amid solvent mists, syncing 12 inputs/outputs to prevent registration errors, maintaining color fidelity at high speeds.

- Semiconductor Handling: In wafer sorters, used in power plants for actuator sequencing or beyond, it drives encoder inputs for capillary alignment, enduring ESD and ensuring micron-level precision.

Compatible or Alternative Products

- ACC-24E2: Non-DB variant for basic terminal block setups.

- ACC-8E: Compact I/O module for smaller channel needs.

- ACC-51E: Encoder interpolator for high-resolution feedback.

- ACC-65E: Pulse/direction interface for third-party motor sync.

- Turbo PMAC2-3U: Host controller for seamless integration.

- ACC-28E: Analog I/O complement for mixed-signal systems.

- NI-9425: National Instruments alternative for LabVIEW environments.

- PMAC2-EC: Enhanced CPU for multi-board coordination.

Setup Notes & Maintenance Insights

Setup: Verify UMAC firmware (v3.0+ via PPMAC query) for full checksum support (I4=1/3). Inspect backplane pins for bends with a continuity tester, cleaning with isopropyl alcohol if needed. Set jumpers (JP1-JP9) for stepper or encoder modes, secure to the rack, and map channels in the IDE. Test with a 20 kHz pulse on one channel, scoping for clean output. Ensure 0.3 m/s airflow in the rack to maintain -40°C to +70°C compliance.

Maintenance: Bi-weekly, check LEDs for fault blinks (amber indicates opto failure); test with a signal generator for >24 V input tolerance. Quarterly, reseat terminal blocks and DB connectors to prevent corrosion, using dielectric grease sparingly. Annually, run a full channel test in the IDE, logging latency; >0.2 ms delays suggest board wear, resolvable via script resets or replacement. Update firmware during downtime, verifying with pulse tests. These steps ensure sustained 20 kHz performance, minimizing disruptions.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626