Description

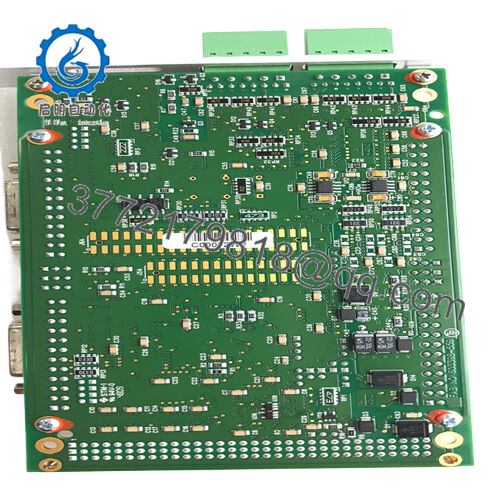

DELTA TAU ACC-24E2A DB 16 functions as a motion control module with an integrated 16-channel DB interface, serving as both the processing core and connectivity hub for mid-sized automation systems. It fits seamlessly into DELTA TAU’s PMAC ecosystem, combining the precision motion control capabilities of the ACC-24E2A series with a high density DB connector array that simplifies wiring to encoders, limit switches, and servo drives. The 16-channel DB interface is engineered for industrial durability, with ruggedized pins and a secure locking mechanism that resists vibration-induced disconnections—a common issue with standard connectors in high-motion environments.

ACC-24E2A DB 16

Internally, the module maintains the same optimized processing architecture as its siblings, with dedicated resources for trajectory planning and real-time feedback, but its external design prioritizes streamlined connectivity: the 16 channels eliminate the need for splitter cables or terminal blocks, reducing wiring complexity by up to 40% in systems with multiple peripherals. In terms of integration, DELTA TAUACC-24E2A DB 16 supports protocols like Ethernet/IP and Modbus TCP/IP, ensuring it communicates smoothly with HMIs and upper-level control systems while its DB interface handles field-level connections.

ACC-24E2A DB 16

Technical specifications:

Model Number ACC-24E2A DB 16

Brand DELTA TAU

Type Motion control module with 16-channel DB interface

Input Voltage 24V DC ±10%

Operating Temp Range -10°C to 65°C (14°F to 149°F)

Mounting Style PMAC backplane or DIN rail mount

Dimensions 160mm x 110mm x 32mm (6.3in x 4.3in x 1.3in)

Weight 420g (14.8oz)

Interface/Bus PMAC backplane, 10/100 Ethernet (1 port), 16-channel DB-15 interface

Compliance CE, UL 61010, RoHS, IEC 61076-2-103 (DB connector standard)

Supported Protocols Ethernet/IP, Modbus TCP/IP, CANopen

Typical Power Draw 6.2W max

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

ACC-24E2A DB 16

Main features and advantages:

The practical value of DELTA TAU ACC-24E2A DB 16 shines in its ability to simplify connectivity without sacrificing performance. For system integrators, the 16-channel DB interface reduces installation time significantly—what once required multiple connectors and terminal blocks can now be wired through a single, secure interface, minimizing the risk of wiring errors that cause costly downtime. This streamlined approach also makes system documentation and future modifications easier, as the DB interface’s pinout is standardized and easily traceable. For maintenance teams, the ruggedized connector design means fewer service calls related to loose connections, especially in high-vibration environments like robotic welding cells or packaging lines. For production engineers, the module’s combination of reliable connectivity and precise motion control ensures that feedback signals from encoders or sensors reach the controller without latency, maintaining tight tolerances (±0.005mm) in processes like CNC machining or automated inspection. Over time, the module’s durable construction—including corrosion-resistant DB pins—ensures consistent performance in humid or dusty environments, extending the intervals between required maintenance.

Application areas:

DELTA TAU ACC-24E2A DB 16 excels in applications where high-density, reliable connectivity is as critical as motion precision. In automated test equipment, it connects to 16 sensors and actuators simultaneously, coordinating motion sequences with data collection from pressure, temperature, and position sensors—all through its DB interface, which ensures synchronized timing between motion and measurement. In packaging machinery, the module controls conveyor systems and robotic pickers while using its 16 channels to monitor photoelectric sensors, ensuring packages are aligned correctly before labeling or sealing. In laboratory automation, it manages precision dispensing robots, with the DB interface connecting to syringe pumps and position encoders to maintain accurate fluid volumes and placement—even in cleanroom environments where wiring clutter must be minimized. In each case, the module’s 16-channel DB interface proves essential to maintaining both connectivity and control.

Related products:

REXROTH R901254695 VT-HNC100-2-3X/N-I-00/000

GE HE693THM666

Triconex 3009

Triconex 3624

Schneider PMC-2/11/04/001/00/03/10/00/10

FIREEYE 95DSS2-1

Tmeic ARND-3110N

smc INR-244-264

GE IC697CPM790

GE IC754VGF15CTD

MacGregor 2141357-804

MacGregor 2141232-802

LAM 839-101612-885

EMC VISATRON VN115/87

Cole Morgan 60WKS-CE240/12PB

TRICONE 3625

TRICONEX 3625

Berger Lahr EXRDM3913/50NEA

TRICONEX 3625

SAACKE HMI10-M REV215

EATON XVS-460-15MP1-1-10

Honeywell HMR2300-D21-485

KONGSBERG RCU502

KONGSBERG RDIOR420

KONGSBERG RSER200-4

KONGSBERG WCC600

GE IS220PDIAH1A

ELAU SM140-30-120-P0-45-M1-B1

GE IS220PDIAH1B

TRICONEX 3625

TRICONEX 3625

Schneider C600/10/1/1/1/00

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONE 3721

TRICONEX 3721

DANIEL DANIEL S600+

schneider XBTGT6340

A-B 1326AB-B720F-21K7-SERIESC

Schneider MICOMP139

PACIFIC SCIENTIFIC BLF2924-10-0-S-017

Rockwell 1794-APBDPV1

Rockwell SST-PB3-SLC

Rusgard LLC GE RS-FS-9001

GE PQMII-C-A

Honeywell IQView8/24

Honeywell IQVIEW4/24

GE F35-W00-VFH-F8L-H6L-M6L-PXX

Yokogawa NFCP100-S05 S3

Woodward 5466-409

TRICONEX 3721

THK TD-020CU-200AC-G15M-5J-N

SIMPLEX 4100-5113

Vibration Monitor AMS3120-A3120/022-000

YOKOGAWA CP451-50S2

HIMA PS1000WR011

YOKOGAWA 3500/22M-01-01-00 288055-01

HONEYWELL FC-SCNT01

Schneider SH30552P11A2000

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626