Description

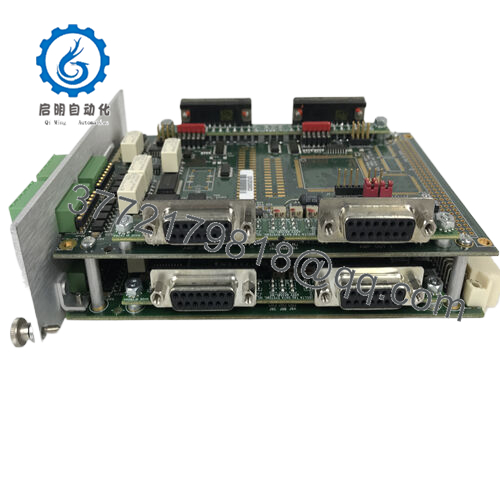

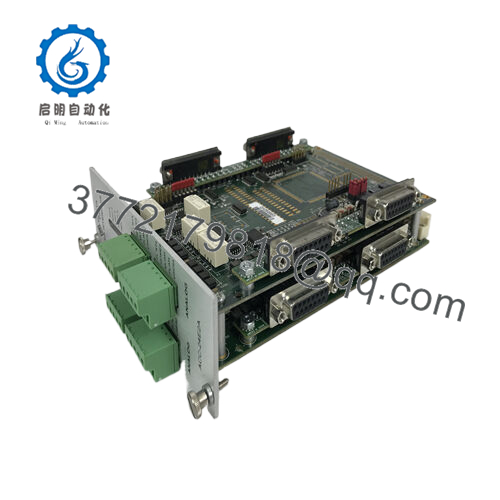

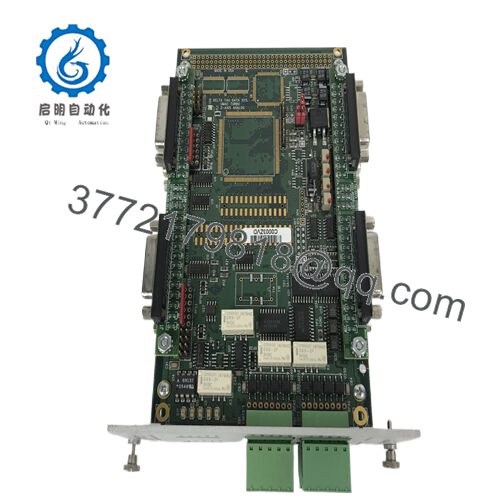

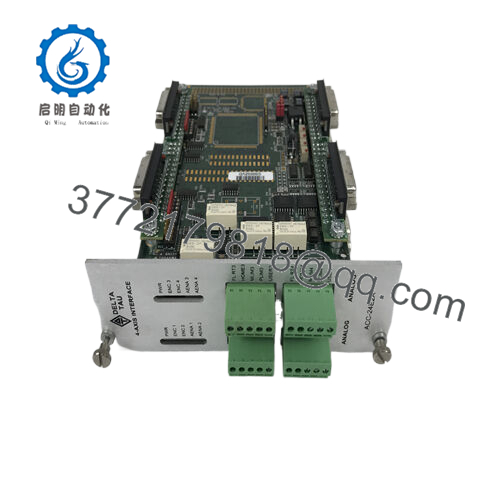

DELTA TAU ACC-24E2A 4-AXIS operates as a dedicated 4-axis motion control module, engineered to serve as the precision core of compact automation systems. It integrates seamlessly into DELTA TAU’s PMAC ecosystem, connecting with I/O modules, servo drives, and feedback devices such as encoders via a streamlined backplane interface. The module’s processing architecture is optimized for 4-axis coordination, with dedicated resources allocated to each axis to ensure smooth, synchronized motion—whether executing simple point-to-point moves or complex interpolated trajectories.

ACC-24E2A 4-AXIS

The module’s processing architecture is optimized for 4-axis coordination, with dedicated resources allocated to each axis to ensure smooth, synchronized motion—whether executing simple point-to-point moves or complex interpolated trajectories. Unlike general-purpose controllers, its 4-axis focus eliminates unnecessary processing overhead, resulting in faster response times (sub-millisecond latency) for the axes that matter. In terms of connectivity, DELTA TAUACC-24E2A 4-AXIS supports essential industrial protocols including Ethernet/IP and Modbus TCP/IP, enabling easy integration with HMIs, PLCs, and supervisory systems. Within the automation stack, it sits at the motion control layer, translating high-level commands into precise motor movements while maintaining constant feedback loops to ensure accuracy.

ACC-24E2A 4-AXIS

Technical specifications:

Model Number ACC-24E2A 4-AXIS

Brand DELTA TAU

Type Compact 4-axis motion control module

Input Voltage 24V DC ±10%

Operating Temp Range -10°C to 65°C (14°F to 149°F)

Mounting Style PMAC backplane or DIN rail mount

Dimensions 145mm x 105mm x 30mm (5.7in x 4.1in x 1.2in)

Weight 380g (13.4oz)

Interface/Bus PMAC backplane, 10/100 Ethernet (1 port)

Compliance CE, UL 61010, RoHS

Supported Protocols Ethernet/IP, Modbus TCP/IP, CANopen

Typical Power Draw 5.8W max

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

ACC-24E2A 4-AXIS

Main features and advantages:

The practical advantages of DELTA TAU ACC-24E2A 4-AXIS become clear in its ability to optimize compact automation systems. For system designers, its reduced size (30% smaller than the 24-axis ACC-24E2) allows for integration into space-constrained enclosures—critical in applications like benchtop robotics or embedded manufacturing cells. This compactness also lowers power consumption, making it suitable for battery-backed or energy-efficient setups. For maintenance teams, the module’s simplified architecture (focused on 4 axes) reduces troubleshooting complexity, with diagnostic tools that isolate issues to specific axes rather than sifting through unnecessary data. For production engineers, the module’s precision ensures that 4-axis processes—such as pick-and-place with orientation control or 3D printing with bed leveling—maintain tight tolerances (±0.005mm) without the latency introduced by larger controllers. Long-term, its rugged design (shock resistance up to 10G) ensures reliability in industrial environments, while field-upgradable firmware extends its useful life as application needs evolve.

ACC-24E2A 4-AXIS

Application areas:

DELTA TAU ACC-24E2A 4-AXIS excels in applications where 4-axis coordination is critical but larger systems are unnecessary. In medical device manufacturing, it controls small robotic arms for assembling precision components, where its compact size fits into cleanroom enclosures and its precision ensures consistent part mating. In electronics testing, the module manages 4-axis probe stations, positioning test probes with micron-level accuracy to contact specific points on circuit boards. In additive manufacturing, it oversees desktop 3D printers with dual extruders and a moving bed, synchronizing the four axes (X, Y, Z, and extruder rotation) to ensure layer adhesion and dimensional accuracy. In each case, the module’s focus on 4-axis performance delivers the precision of larger controllers without the excess bulk or cost.

ACC-24E2A 4-AXIS

Related products:

Before installing DELTA TAU ACC-24E2A 4-AXIS, verify that the PMAC backplane (if used) has firmware version 5.0 or higher to support the module’s 4-axis optimization. For DIN rail installations, ensure the mounting surface can support the module’s weight plus connected cables, and that there’s at least 20mm of clearance for cooling.

During setup, confirm that feedback devices (encoders) are calibrated to the module’s 4-axis layout—misalignment here can introduce positioning errors. Torque mounting hardware to 0.3 N·m to prevent vibration-induced loosening, especially in mobile applications like robotic carts. For maintenance, perform quarterly checks of axis status LEDs: a steady green light per axis indicates normal operation, while a red light flags issues specific to that axis. Annually, inspect Ethernet and power connections for corrosion (common in humid environments) and update firmware to access the latest motion control algorithms.

Other product models:

REXROTH R901254695 VT-HNC100-2-3X/N-I-00/000

GE HE693THM666

Triconex 3009

Triconex 3624

Schneider PMC-2/11/04/001/00/03/10/00/10

FIREEYE 95DSS2-1

Tmeic ARND-3110N

smc INR-244-264

GE IC697CPM790

GE IC754VGF15CTD

MacGregor 2141357-804

MacGregor 2141232-802

LAM 839-101612-885

EMC VISATRON VN115/87

Cole Morgan 60WKS-CE240/12PB

TRICONE 3625

TRICONEX 3625

Berger Lahr EXRDM3913/50NEA

TRICONEX 3625

SAACKE HMI10-M REV215

EATON XVS-460-15MP1-1-10

Honeywell HMR2300-D21-485

KONGSBERG RCU502

KONGSBERG RDIOR420

KONGSBERG RSER200-4

KONGSBERG WCC600

GE IS220PDIAH1A

ELAU SM140-30-120-P0-45-M1-B1

GE IS220PDIAH1B

TRICONEX 3625

TRICONEX 3625

Schneider C600/10/1/1/1/00

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONE 3721

TRICONEX 3721

DANIEL DANIEL S600+

schneider XBTGT6340

A-B 1326AB-B720F-21K7-SERIESC

Schneider MICOMP139

PACIFIC SCIENTIFIC BLF2924-10-0-S-017

Rockwell 1794-APBDPV1

Rockwell SST-PB3-SLC

Rusgard LLC GE RS-FS-9001

GE PQMII-C-A

Honeywell IQView8/24

Honeywell IQVIEW4/24

GE F35-W00-VFH-F8L-H6L-M6L-PXX

Yokogawa NFCP100-S05 S3

Woodward 5466-409

TRICONEX 3721

THK TD-020CU-200AC-G15M-5J-N

SIMPLEX 4100-5113

Vibration Monitor AMS3120-A3120/022-000

YOKOGAWA CP451-50S2

HIMA PS1000WR011

YOKOGAWA 3500/22M-01-01-00 288055-01

HONEYWELL FC-SCNT01

Schneider SH30552P11A2000

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626