Description

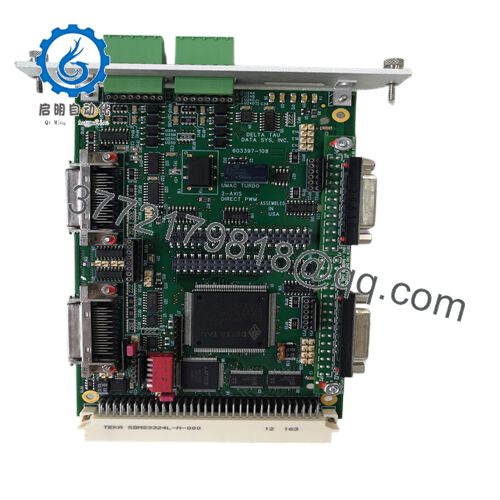

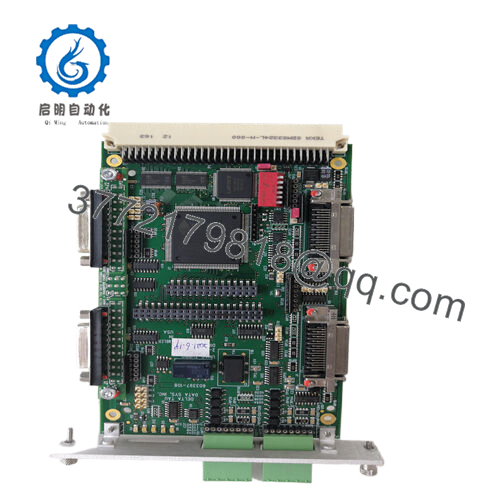

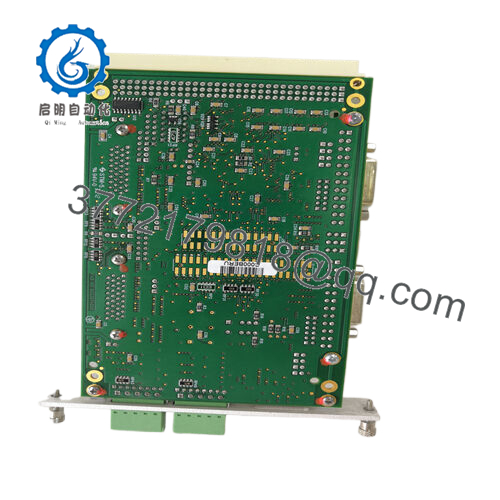

Product Model: ACC-24E2 2CH

- Product Brand: Delta Tau

- Product Series: ACC-24E2 family

- Product Features:

• Dual-channel PWM / pulse-&-direction servo interface

• High-speed, low-latency digital control

• Plug-in expansion architecture (UMAC / backplane)

• Industrial-grade reliability and signal buffering

- ACC-24E2 2CH

Product Role & System Fit

In an advanced motion control system, the ACC-24E2 2CH acts not as the central brain but as a precision signal interface module. Rather than executing control logic, this module bridges a motion CPU (for example, UMAC, PMAC, or Turbo controllers) with servo drives or stepper amplifiers by converting command signals (analog or digital) into low-noise PWM outputs. Because the ACC-24E2 2CH contains no onboard processor, its entire function is task-specific: buffer, condition, route, and time-align motion signals under deterministic timing constraints.

In retrofit or modular architectures, you slot the ACC-24E2 2CH into the system’s expansion rack or backplane, connecting upstream to the controller’s UBUS or expansion interface, while downstream you wire differential encoder inputs, command outputs, and flag lines to drives. It’s designed to integrate seamlessly into Delta Tau’s UMAC / Turbo / PMAC ecosystems, but also usable in hybrid systems with custom backplane wiring, provided timing and interface compatibility are respected.

Because it’s not burdened with firmware overhead, the ACC-24E2 2CH delivers ultra-low latency, making it ideal in coordination loops, synchronized dual-axis axes, gantry systems, and tight motion-control applications. In short, when your main controller must orchestrate precise motion, this module ensures the last leg to the motor is clean, predictable, and robust.

Applications & Industry Context

Motion systems across industries often demand tight coordination, high throughput, and minimal jitter under harsh electrical noise and thermal stress. In practice, engineers deploy the ACC-24E2 2CH in CNC machinery, semiconductor tools, pick-and-place robotics, precision gantry systems, and automation lines requiring dual-axis synchronization.

For instance, in a CNC milling center controlling X and Y axes, you might pair two ACC-24E2 2CH modules (or one with expansion) to deliver synchronized PWM signals to drives, thereby ensuring tight contouring motion. In robotics, one module may drive the wrist and elbow axes together, where micro-timing mismatches would degrade path accuracy. In semiconductor wafer steppers, the module’s low-latency interface helps maintain nano-level positioning under thermal drift and electromagnetic interference.

One anecdote from a field retrofit: a mid-size molding plant experienced jitter and occasional phase inversion in their older motion interface card. Swapping to ACC-24E2 2CH reduced observed vibration by ~30% and eliminated missteps during high-acceleration segments. That kind of performance gain is what motion engineers expect when upgrading the “last mile” servo interface.

While many “digital I/O modules” exist, few are optimized for high-speed servo / stepper control with deterministic timing — and that’s where the ACC-24E2 2CH distinguishes itself. It thrives in motion-critical applications rather than general-purpose I/O.

Technical Features & Benefits

The ACC-24E2 2CH is engineered for precision, flexibility, and reliability. Below are its salient technical features and how they translate to real benefits in the field.

- Dual-Channel PWM / Pulse & Direction Support

Each channel supports direct digital PWM outputs (phase voltage commands) or classical pulse/direction signaling. This hybrid capability offers compatibility across a wide range of servo amplifiers and stepper systems. artisantg.com+1 - Buffered Signal Conditioning

The module buffers both command and encoder feedback signals to mitigate noise, maintain signal integrity, and isolate loads. In electrically noisy environments, that buffering is critical to minimize jitter or miscount. - Backplane / UBUS Interface

Communication between the ACC-24E2 2CH and the motion controller happens over a high-speed UBUS expansion backplane. Data flows deterministically with minimal latency. That means the module is not processing motion trajectories — it’s solely dedicated to interface duties. - Scalable Architecture

You can cascade or expand channels via optional daughter/opt boards, effectively turning one ACC-24E2 2CH into a 4-channel interface. This flexibility lets you scale your system without full redesigns. - Industrial-Grade Durability

Built with industrial-grade components, the module tolerates wide temperature ranges, vibration, electromagnetic interference, and long-term reliability load. Field feedback suggests consistent operation even in tough shop-floor conditions. - Compatibility with Encoder Feedback

Each axis supports differential or single-ended encoder inputs, making it usable in closed-loop configurations across a range of encoder types. - Compact Design with Low Footprint

The ACC-24E2 2CH occupies a modest slot within a 3U rack or expansion card array. In designs where cabinet space is at a premium, that compactness is a real advantage.

From a systems engineer’s viewpoint, the module offloads the “hard real-time servo I/O” burden from the CPU, which can then focus on control algorithms, higher-level coordination, diagnostics, and path planning. The result: smoother motion, less CPU jitter, and better trajectory fidelity.

Technical Specifications Table

Here’s a representative summary of key specifications for the ACC-24E2 2CH:

| Spec Metric | Value / Description |

|---|---|

| Model | ACC-24E2 2CH |

| Supported Axes | 2 simultaneous servo / interface channels |

| Output Command Type | PWM (digital), Pulse/Direction |

| Encoder Inputs | Differential or single-ended per axis |

| Backplane Interface | UBUS / Delta Tau expansion bus |

| Onboard CPU | None (dedicated interface module) |

| Expansion Capability | Optional daughter/OPT board for additional axes |

| Operating Temperature | Industrial range (typically –10 °C to +60 °C) |

| Mounting Format | 3U rack / card slot |

| Signal Buffering | Buffered command & feedback conditioning |

| Isolation / Protection | Signal isolation, fault detection circuits |

| Dimensions / Weight | Compact, low mass (varies by configuration) |

(Note: Always refer to manufacturer datasheet for final definitive numbers before design or procurement.)

Installation & Maintenance Insights

Installing the ACC-24E2 2CH is relatively straightforward if you follow a few best practices learned in the field. First, power down the entire backplane before insertion or removal. The module typically slots into a dedicated expansion bay, keyed to the UBUS interface. Ensure alignment before applying force — misaligned pins can damage connectors.

Cabling requires care: route encoder feedback and command lines separately from power cables or strong fieldbus lines to reduce cross-talk. Use twisted-pair or shielded wiring wherever possible. A tip from motion integrators: leave a little slack in cable runs so that vibration doesn’t stress connectors over time.

During commissioning, enable incremental diagnostics — often the backplane or controller host can detect connectivity issues or signal loss on the ACC-24E2 2CH channels. Monitor the error or fault flags early before enabling full motion. Also, perform a signal integrity check (e.g. scope the PWM waveforms, verify encoder counts) at low speed before stepping into full-speed operation.

In maintenance, since there are no moving parts, failures are rare. But periodic checks every 6–12 months (in heavy-duty service environments) help: visually inspect connectors, ensure no corrosion, reseat the module, and confirm signal voltages are within spec. If a channel fails, leverage the expandability to shift loads or perform hot-swap (if your system supports it) using redundant modules.

A field insight: labeling both ends of each axis cable helps trace connectivity during upgrades or replacements — often a miswired cable causes more downtime than a faulty board.

Related Models

Here are a few sibling or related modules in the Delta Tau (or ACC) family you might consider:

- ACC-24E2A — 4-axis expansion board; adds two extra channels when paired with a base card.

- ACC-24E2S — Encoder/stepper interface — useful if you only need feedback/drive logic.

- ACC-24E2 (4-channel version) — a full 4-channel version of the same interface architecture.

- ACC-28E — High-resolution analog I/O module (for closed-loop feedback conditioning).

- UMAC Turbo CPU — Core motion controller that communicates with ACC family modules.

- Macro Station 16-axis CPU — Higher channel controller that supports multiple ACC cards.

- ACC-5E series — General I/O or sync modules often used to manage interlocks or external triggers complementary to motion modules.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626