Description

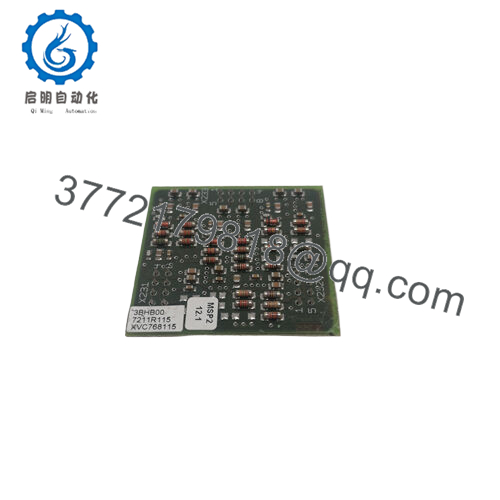

ABB XVC768115 3BHB72111R115 is an advanced interface module that is a core component of ABB’s comprehensive suite of industrial automation and control products. This product suite is renowned for its reliability, innovation, and wide range of applications in various industries. As an interface module, ABB XVC768115 3BHB72111R115 serves as a bridge between different components within the control system.

XVC768115 3BHB72111R115

In the architecture of the control system, it serves as a communication hub. It receives data from various input devices (such as sensors) and transmits the processed information to output devices (such as actuators). For example, in a distributed control system (DCS), it can connect field devices directly involved in physical processes with high-level control units that make strategic decisions. Engineers and system integrators value the versatility of ABB XVC768115 3BHB72111R115. It supports multiple communication protocols, simplifying the process of integrating devices from different manufacturers into a unified control system. This reduces the complexity of system design and implementation, saving time and resources. In addition, its high-quality construction and reliable performance ensure that it can operate seamlessly in harsh industrial environments, providing stable and efficient data transmission solutions.

XVC768115 3BHB72111R115

Main features and advantages:

With its high-performance processing capability, it is able to process large amounts of data in real-time. In industrial environments, millisecond differences can be crucial, and this fast data transmission rate ensures that control decisions can be made quickly. For example, on high-speed packaging lines, it can quickly transmit product positioning information to packaging machinery, achieving accurate and efficient packaging operations.

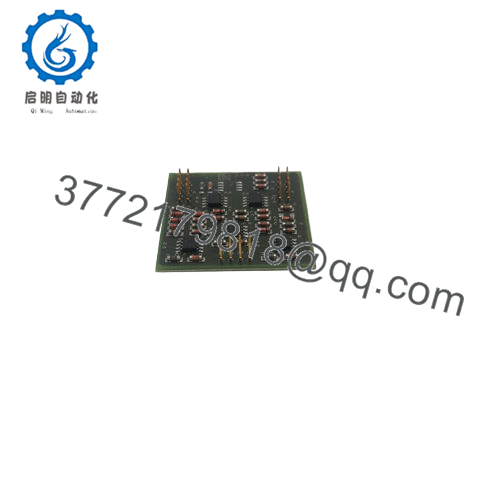

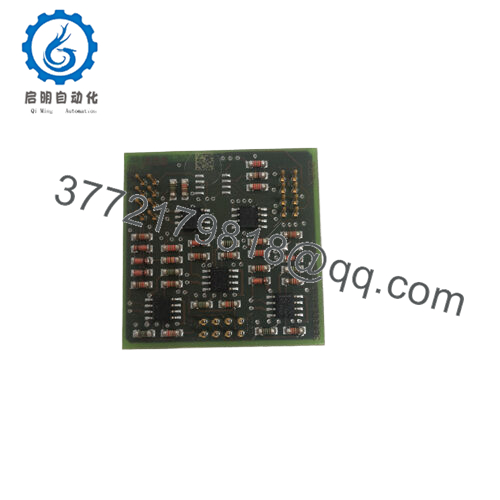

The hardware design of ABB XVC768115 3BHB72111R115 is both robust and compact. It is designed to withstand harsh conditions in industrial environments and can operate reliably in environments with high electrical noise, vibration, and temperature fluctuations. Its compact size makes it easy to install in the control cabinet, even in limited space. The design of the module also includes advanced shielding technology to prevent electromagnetic interference and ensure the integrity of transmitted data.

In terms of compatibility, this interface module performs excellently. It supports multiple industry standard communication protocols, such as Modbus TCP, Profibus DP, and EtherNet/IP. This makes it very flexible and able to integrate with various devices, regardless of their brand or origin. Whether it’s connecting legacy equipment in old manufacturing plants or integrating with the latest intelligent sensors in state-of-the-art facilities, ABBXVC768115 3BHB72111R115 can easily handle it.

In terms of long-term reliability, ABB has designed ABB XVC768115 3BHB72111R115 using high-quality components. These components have been carefully selected to withstand the test of time and continuous use. This module also has a self diagnostic function, which can detect and report any potential issues to prevent problem escalation. This proactive maintenance approach helps to minimize downtime and ensure that the industrial processes it supports can operate continuously and efficiently.

XVC768115 3BHB72111R115

Technical specifications:

Model XVC768115 3BHB72111R115

Brand ABB

Type interface module

Power supply 24 VDC (± 10%)

Working temperature -20 ° C to 60 ° C

Installation method: DIN rail installation

Size 100mm x 80mm x 50mm

Weight 0.3 kg

Ethernet interface RS – 485、Profibus DP

Certification CE, UL

Ethernet data transmission rate up to 100 Mbps

RS-485 data transmission rate up to 115.2 kbps

Environmental grade IP20

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

XVC768115 3BHB72111R115

Application areas:

In large manufacturing plants, such as automobile factories, it plays a crucial role in coordinating the numerous sensor and actuator networks on the production line. These factories rely on a large number of equipment to control tasks such as robot welding, painting, and assembly. ABB XVC768115 3BHB72111R115 ensures accurate transmission and processing of data from sensors (used to detect parameters such as robotic arm position or weld quality). This enables real-time adjustments, minimizing errors and optimizing production speed to the greatest extent possible.

The power generation facilities also heavily rely on ABB XVC768115 3BHB72111R115. In power plants, whether they are coal-fired power plants, gas-fired power plants, or renewable energy power plants, a large number of monitoring and control equipment are installed. This product helps manage communication between different components such as voltage regulators, frequency controllers, and distribution systems. It can transmit data related to electrical parameters, ensure grid stability, and efficiently generate and distribute electricity.

In process industries such as chemical engineering, precise control of temperature, pressure, and flow is crucial. ABB XVC768115 3BHB72111R115 manages the interfaces between various control circuits. It ensures that signals from sensors measuring these key parameters can be accurately transmitted to the central control system, thereby achieving precise process control and preventing any potential safety hazards or low production efficiency issues.

Related products:

ABB XVC768AE101- a closely related current monitoring board that can be used in conjunction with ABB XVC768115 3BHB72111R115 to provide additional electrical parameter monitoring capabilities and achieve a more comprehensive control solution.

ABB 3BSE003911R115- Another module from ABB, although with different main functions, can be integrated with ABB XVC768115 3BHB72111R115 to expand the overall capabilities of the control system, such as in data processing or interface with specific types of equipment.

ABB AI810 Analog Input Module – This module can be connected to ABB XVC768115 3BHB7211R115, enabling the interface module to process analog input signals from various sensors, enhancing the system’s ability to monitor and control processes that rely on analog data.

ABB AO810 Analog Output Module – Complementary to the Analog Input Module, it can be used with ABB XVC768115 3BHB72111R115 to output analog signals to actuators for precise control of analog equipment in industrial processes.

ABB DI810 Digital Input Module – facilitates the connection of digital sensors to ABB XVC768115 3BHB72111R115, expanding the system’s ability to process digital input signals, which is crucial for monitoring the status of binary state devices in industrial control systems.

ABB DO810 Digital Output Module – Used in conjunction with ABB XVC768115 3BHB7211R115, it sends digital output signals to control digital actuators in industrial applications, such as relays and solenoid valves.

ABB Communication Gateway Module – can be integrated with ABB XVC768115 3BHB72111R115 to further enhance communication capabilities, especially when dealing with complex network topologies or requiring interfaces with different types of networks.

Installation and maintenance:

Before installing ABBXVC768115 3BHB72111R115, it is necessary to ensure that the control cabinet environment is suitable. Check the available space inside the cabinet; The module should be installed in an area with sufficient clearance to ensure proper ventilation. Due to its use of a 24 VDC power supply, please verify if the power supply is stable and the voltage output is correct. Grounding is also crucial. Ensure that the module is properly grounded to prevent electrical surges and interference that may interfere with its operation.

For maintenance, it is recommended to conduct regular visual inspections. Look for any signs of physical damage, such as cracked casing or loose connections. Regularly conduct communication testing to ensure that the module transmits and receives data correctly. ABB often releases firmware updates for its products, so it is essential to keep the firmware of ABB XVC768115 3BHB72111R115 up-to-date. These updates may include error fixes, performance improvements, and enhanced compatibility. Please carefully follow ABB’s official firmware update guide to avoid any issues during the update process. By following these installation and maintenance practices, you can ensure the long-term reliable operation of ABB XVC768115 3BHB72111R115 in your industrial control system.

Other ABB product models:

ABB 3AUA0000036521

ABB 3AUA0000110430

ABB 3BDS005799R1 PM665

ABB 3BHB003688R0101

ABB 3BHB003688R0101

ABB 3BHB003689

ABB 3BHB003689

ABB 3BHB003689

ABB 3BHB003689 3BHB003688R0101

ABB 3BHB005243R0105

ABB 3BHB005243R0106 KUC755AE106

ABB 3BHB005243R0117

ABB 3BHB005245R0101

ABB 3BHB005922R0001

ABB 3BHB006309R0001

ABB 3BHB006338R0001

ABB 3BHB006714R0217 SYN 5201a-Z.V217

ABB 3BHB006715R0277

ABB 3BHB007030R0102 UFC760BE102

ABB 3BHB012961R0002

ABB 3BHB015651P0001

ABB 3BHB015651P0001

ABB 3BHB015651P0001

ABB 3BHB015651P0001

ABB 3BHB030310R0001

ABB 3BHB043807R0001

ABB 3BHB043808R0001

ABB 3BHE003604R0102

ABB 3BHE003604R0106

ABB 3BHE004573R0142

ABB 3BHE006373R0101

ABB 3BHE006412R0101

ABB 3BHE009681R0101

ABB 3BHE014377R0001 PVD164

ABB 3BHE017628R0002 PPD115A02 SG579989013

ABB 3BHE022293R0101

ABB 3BHE022293R0101

ABB 3BHE022294R0101 GFD233

ABB 3BHE023784R0001

ABB 3BHE024313R0101 KSD211A101

ABB 3BHE024577R0101

ABB 3BHE024577R0101 11790750105 PPC907BE

ABB 3BHE024747R0101

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626