Description

Real-World Use & Application Scenarios

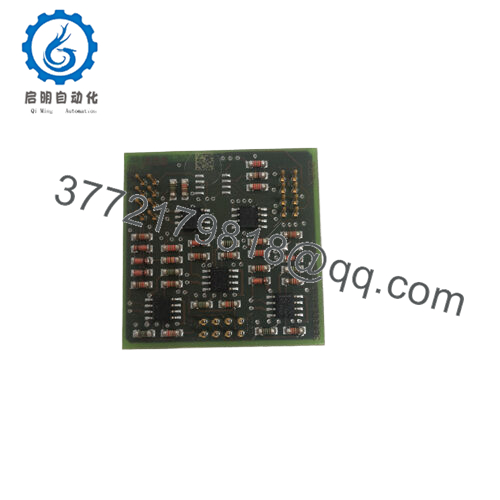

The ABB XVC768115 3BHB72111R115 pulse output module is mainly used in industrial automation environments where precise feedback and pulse signals are critical to system performance. Typically integrated into programmable logic controller (PLC) systems and drive control setups, this module manages the pulse output necessary for applications such as motor speed feedback, encoder signal processing, and real-time pulse generation.

It is widely applicable in manufacturing plants, processing facilities, and complex machine automation, where operators rely on accurate pulse data to regulate motor speed, positioning, and process timings. The ABB XVC768115 3BHB72111R115 addresses challenges related to pulse signal integrity and synchronized data exchange, making it vital in control systems demanding high-speed and high-accuracy pulse output handling.

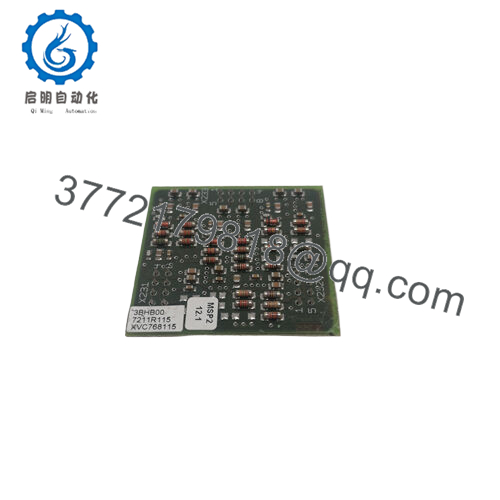

- XVC768115 3BHB72111R115

Product Introduction & Positioning

The ABB XVC768115 3BHB72111R115 is a specialty I/O module designed to generate pulse outputs from PLC controllers with high precision. It operates on a 24 V DC power supply and supports configurable input and output settings, allowing it to be tailored to specific pulse signal requirements in industrial control networks.

This module fits into ABB’s automation ecosystem to enhance motor control systems, drive feedback loops, and real-time synchronization tasks. Engineers and system designers appreciate its reliability in maintaining signal consistency and minimizing pulse loss, which is critical for functional accuracy in applications like conveyors, robotics, and packaging machinery.

Equipped with Modbus TCP communication, the module integrates smoothly into networked automation architectures, enabling seamless data flow and centralized control.

Key Technical Features & Functional Benefits

The ABB XVC768115 3BHB72111R115 supports up to 32 configurable pulse inputs and outputs, accommodating diverse automation requirements. It honors stringent timing and synchronization specifications vital for precision control and motion feedback.

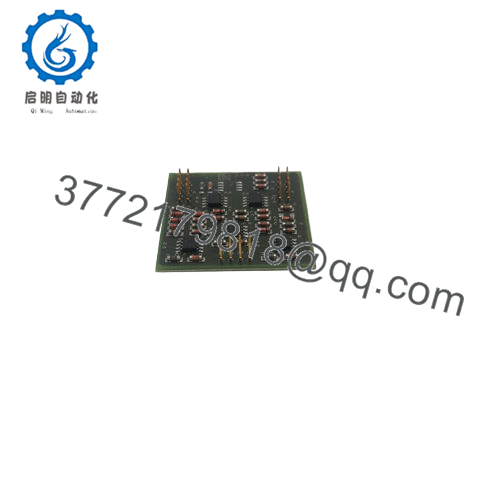

Its compact design (approximately 100 mm x 140 mm x 75 mm) facilitates installation in space-limited control cabinets without compromising functionality. Operating reliably within ambient temperatures from -20°C to 60°C, the module suits varied industrial environments.

The Modbus TCP communication protocol enables efficient, real-time data exchange between the pulse output module and PLC or supervisory systems, thereby optimizing process control accuracy and responsiveness.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | XVC768115 3BHB72111R115 |

| Brand | ABB |

| Product Type | Pulse Output I/O Module |

| Power Supply | 24 V DC |

| Input Channels | Up to 32 Configurable |

| Communication Protocol | Modbus TCP |

| Operating Temperature Range | -20°C to +60°C |

| Dimensions (L x W x H) | 100 mm x 140 mm x 75 mm |

| Weight | Approx. 0.4 kg |

Related Modules or Compatible Units

DO810 3BSE008510R1 – Digital output module compatible with pulse generation systems.

DI810 – Digital input module complementing feedback loops for complete signal management.

PM866-2 – Industrial controller module integrating pulse feedback for advanced control.

PU519 – Real-time accelerator module supporting high-speed data processing.

REG216 – Numerical protection relay enhancing system safety along with pulse modules.

Installation Notes & Maintenance Best Practices

Install the ABB XVC768115 3BHB72111R115 in a vibration-free, well-ventilated environment inside standard control panels. Ensure all electrical connections meet ABB’s specifications for shielding and grounding to avoid interference in pulse signal transmission.

Maintenance includes periodic verification of pulse signal integrity using diagnostic tools and monitoring communication logs. Firmware updates and cleaning dust accumulation from connectors bolster module performance and longevity.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626