Description

The ABB VBX01TA finds extensive use in industrial automation environments where precise digital input/output control is crucial. It is particularly prevalent in process plants, power generation facilities, and advanced manufacturing sectors where large-scale distributed control systems are employed. In these settings, managing diverse sensors and actuators reliably is vital to maintaining operational efficiency and safety. The ABB VBX01TA excels in capturing discrete signals from field devices, including proximity sensors, switches, and alarms, and controlling actuators such as valves, relays, and indicators. This makes it indispensable in industries like chemical processing, oil and gas, and utility management, where remote, rapid, and dependable digital communication between field devices and control systems is non-negotiable. Its deployment enables engineers to monitor critical control points with confidence, respond swiftly to changes, and ensure process continuity amidst the challenges of electrically noisy or harsh conditions.

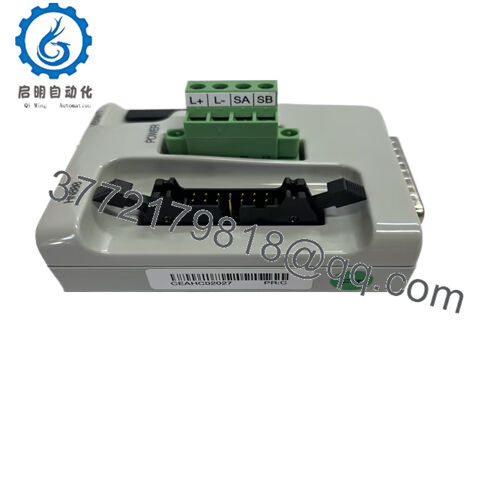

The ABB VBX01TA is a high-performance digital I/O module designed as an interface handler within ABB’s modular control platforms, including the AC500 PLC and HN800 distributed control system families. It functions as a critical part of the control system architecture, bridging field devices and central processors by managing up to 16 discrete digital inputs and 16 outputs. The module is engineered to integrate seamlessly with ABB’s communication infrastructure, ensuring swift data exchange and synchronization within automated processes. Its role is foundational for engineers and system integrators building scalable, reliable control architectures capable of expansion and adaptation across complex industrial sites. The modular compactness of the ABB VBX01TA facilitates dense installations while supporting high-speed signal processing and diagnostics, making it a versatile choice for upgrades or new system designs.

- VBX01TA

- VBX01TA

From a technical standpoint, the ABB VBX01TA offers rapid response times that can reach as low as 2 milliseconds, a feature critical for real-time control in fast-moving processes. The hardware design incorporates conformal coating and industrial-grade components that withstand dust, moisture, and temperature extremes ranging from -20°C to +60°C. Its electrical isolation rating of 1500 volts AC protects sensitive electronics from interference and ground faults, ensuring signal integrity over long cable runs and in electrically harsh environments. The module’s support for multiple industrial communication protocols makes it compatible with legacy and modern systems, enhancing integration flexibility. Over years of continuous operation, the ABB VBX01TA remains durable, with minimal maintenance requiring only periodic inspection and diagnostics checks, thus reducing total cost of ownership in demanding industrial ecosystems.

| Parameter | Value |

|---|---|

| Model | ABB VBX01TA |

| Brand | ABB |

| Product Type | Digital Input/Output Module |

| Number of Channels | 16 digital inputs + 16 digital outputs |

| Operating Voltage | 12–24 V DC (±10%) |

| Switching Current | 1 A per channel |

| Response Time | ≤ 2 milliseconds |

| Electrical Isolation | 1500 V AC |

| Operating Temperature | -20°C to +60°C |

| Protection | Conformal coating, industrial grade |

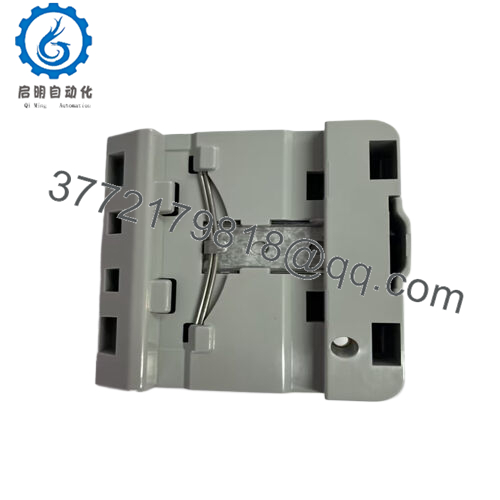

| Mounting | DIN rail or control cabinet |

| Dimensions | Standard modular size |

Related modules to the ABB VBX01TA include ABB VBX01BA, a bus extender module for system communication expansion; ABB AC500 CPU series, providing scalable processing power; ABB AI810, an analog input module for mixed signal integration; ABB DO810, digital output module complementing input capabilities; ABB HN800 rack system, supporting modular control assemblies; ABB PP846, a process controller enhancing system versatility; and ABB DI810, digital input extension for high-density installations.

Installation of the ABB VBX01TA requires attention to cabinet layout, ensuring sufficient space for ventilation and access, as well as proper electrical grounding to minimize noise interference. Field wiring should be organized to avoid crossing high-power cables that can cause EMI issues. Mechanical keying and clear labeling simplify assembly and reduce human error during system expansion or maintenance. Integrators should verify module firmware compatibility and perform initial diagnostics using ABB’s standardized commissioning tools.

Maintenance practices prioritize regular visual inspections to detect any dust or moisture ingress, routine checks on LED status indicators, and validation of input/output signal integrity through system diagnostics. Periodic firmware updates and configuration backups using ABB’s software suite ensure the module adapts to evolving plant requirements and cybersecurity standards. Proper documentation of maintenance activities and system changes enhances long-term reliability and simplifies troubleshooting.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626