Description

Real-World Use & Application Scenarios

The ABB UFD203A101 3BHE019361R0101 is a high-performance industrial control module widely deployed in sectors like oil and gas pipeline monitoring, power plant turbine control, automotive manufacturing, and chemical processing industries. Built to handle complex control and automation tasks, this module is essential in applications requiring continuous, accurate signal processing and system reliability under harsh conditions.

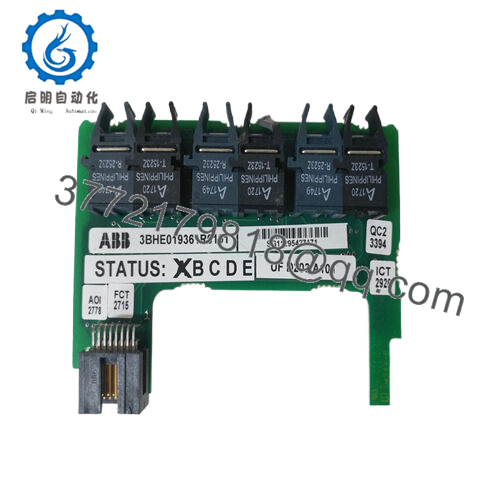

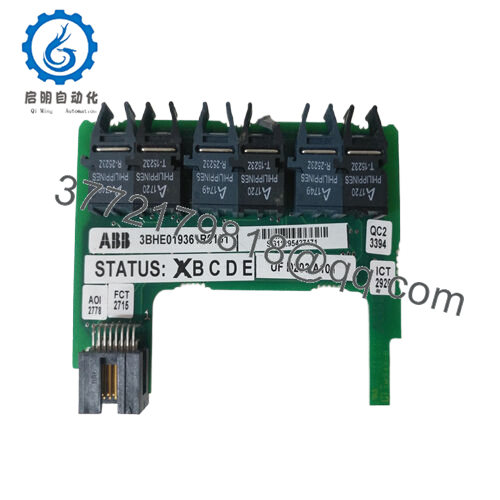

- UFD203A101 3BHE019361R0101

- UFD203A101 3BHE019361R0101

It is commonly used in critical process environments where real-time control and high-speed data acquisition affect operational safety, efficiency, and quality. Control systems integrating the ABB UFD203A101 benefit from its precision in signal handling and robustness against vibration, temperature fluctuations, and electromagnetic interference — common challenges in demanding industrial automation.

Engineers and automation specialists trust this module to optimize production line control, maintain equipment integrity, and ensure long-term operational reliability, making it a versatile component in advanced industrial controllers.

Product Introduction & Positioning

The ABB UFD203A101 3BHE019361R0101 control module features a rugged design with advanced semiconductor technology, ensuring energy efficiency exceeding 96%. It is designed to operate seamlessly within ABB’s broad automation ecosystem, supporting a wide range of digital and analog inputs and outputs for versatile control tasks.

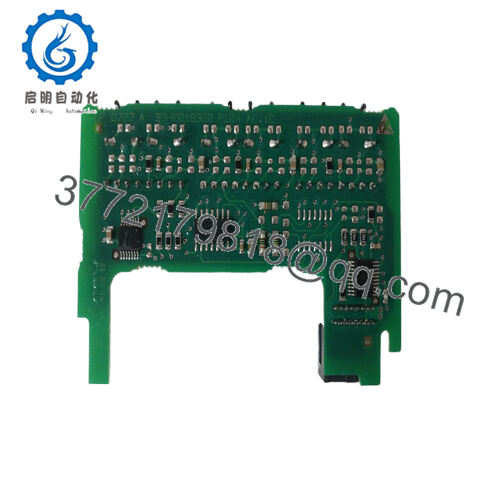

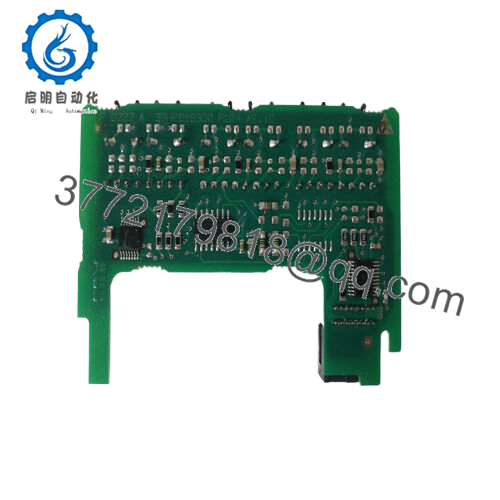

This module’s core strength lies in its ability to maintain a high operating frequency of 30 kHz ±5%, facilitating rapid and precise signal processing critical to real-time industrial control applications. Built with a dual-layer printed circuit board (PCB) and reinforced insulation, the ABB UFD203A101 offers exceptional durability in high-vibration and high-temperature environments.

Compatible with various ABB platforms and configurable to specific industrial needs, it provides an essential bridge between field instruments and control applications, enabling smooth data flow and process management.

Key Technical Features & Functional Benefits

The ABB UFD203A101 delivers superior performance with a high operating frequency of 30 kHz, allowing for accurate, high-speed processing essential for modern automation processes. Its power-efficient design minimizes energy consumption while maintaining robust performance.

Its dual-layer PCB with reinforced insulation technology ensures extended component lifespan, particularly valuable in environments subject to mechanical stress and vibration. The module operates reliably across a wide temperature range (-40°C to +70°C), maintaining operational stability in diverse conditions.

Designed for industrial-grade IP65 protection, the module withstands dust and moisture ingress, further enhancing its suitability for harsh industrial sites. Multiple analog and digital I/O channels enable flexible application across complex control architectures.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | UFD203A101 3BHE019361R0101 |

| Brand | ABB |

| Product Type | Industrial Control Module |

| Operating Frequency | 30 kHz ±5% |

| Input Voltage | 220 V AC ±10% |

| Operating Temperature Range | -40°C to +70°C |

| Protection Class | IP65 |

| Dimensions (L x W x H) | 90 mm x 75 mm x 60 mm |

| Weight | Approx. 0.2 kg |

| I/O Types | Analog and Digital Inputs |

| Energy Efficiency | Over 96% |

Related Modules or Compatible Units

PM866-2 – Controller module for advanced industrial automation and control.

PU519 – Real-Time Accelerator module enhancing speed and data processing capabilities.

DO810 – Digital output module pairing with control modules for comprehensive signal control.

REG216 – Numerical protection relay commonly used alongside industrial controllers.

IDPG 940128102 – Signal processing module compatible with ABB automation systems.

Installation Notes & Maintenance Best Practices

Install the ABB UFD203A101 in well-ventilated control cabinets protecting it from dust and excessive moisture. Ensure precise electrical grounding and shielding to minimize interference and maintain signal integrity. Follow ABB guidelines for wiring and connection to avoid mechanical stress on terminals.

Regular maintenance involves inspecting for physical damage, verifying communication and I/O status, and cleaning accumulated dust to maintain thermal efficiency. Periodic firmware updates should be applied to benefit from enhancements and security updates provided by ABB.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626