Description

What This Product Solves

In the layered intricacies of distributed control systems, where real-time signal acquisition from field devices underpins everything from batch sequencing to continuous throughput, engineers routinely confront the pitfalls of inconsistent digital interfacing—erratic ON/OFF states that skew logic execution, delay fault propagation, or strain system-wide diagnostics in high-density I/O racks. These challenges intensify in environments like petrochemical refineries juggling valve interlocks or food processing lines syncing conveyor sensors, where even fleeting input glitches can cascade into quality variances or safety overrides. The ABB UFC911B106 3BHE037864R0106 steps forward as a robust digital input module in ABB’s Universal Function Control lineup, engineered to capture and condition discrete signals with unwavering precision, ensuring your DCS interprets every switch closure as intended.

This module asserts its necessity in process control setups demanding high reliability for modular expansions—envision a wastewater treatment facility monitoring pump statuses amid corrosive effluents, or an automotive assembly hall tracking fixture triggers during shift ramps. Lacking a dependable handler like the ABB UFC911B106 3BHE037864R0106, operations grapple with noise-induced false triggers or integration silos that complicate troubleshooting, elevating mean time to resolution and compliance risks under IEC 61131 standards. It overcomes these by delivering galvanically isolated channels that filter electromagnetic disturbances, mapping raw binary data directly into the controller’s logic solver for seamless handoff, without the overhead of external conditioning gear.

Central to its appeal in industrial automation is the emphasis on scalable diagnostics: embedded status relays and debounce logic adapt to pulse widths from relays to proximity switches, minimizing engineering tweaks for diverse field inventories. For teams scouting I/O enhancements, the ABB UFC911B106 3BHE037864R0106 transcends basic acquisition—it’s a foundational stabilizer that curbs downtime in signal-dense architectures, where digital fidelity directly correlates to output consistency. By resolving the friction between field realities and control imperatives, it enables agile responses to process shifts, fortifying uptime in setups where every input echoes through the production chain, and precision isn’t a luxury but a baseline for sustained efficiency.

How the Product Works & Fits into a System

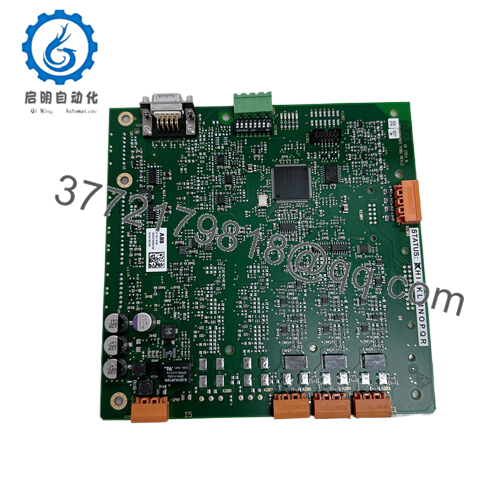

Fundamentally, the ABB UFC911B106 3BHE037864R0106 serves as a gateway for discrete field data, accepting up to 16 isolated digital inputs—typically 24 V DC wet or dry contacts—and debouncing them against chatter to yield clean binary states for the host controller’s scan cycle. It employs optocouplers for channel isolation, safeguarding against ground loops while configurable jumpers set wetting voltages or enable counters for pulse tallying, with outputs routed via backplane signals to trigger function blocks like timers or interlocks. Front-facing LEDs mirror input states for local verification, and a diagnostic port exposes fault counters via serial query, all drawing from a fused power rail to maintain integrity under load dumps.

Within the automation stack, this module resides in the fieldbus or I/O subsystem of ABB’s 800xA DCS or AC 800M PLCs, snapping onto S800 racks or DIN rails where it communicates over PROFIBUS DP or Ethernet/IP, populating process images with timestamped edge events for precise sequencing. In a layered hierarchy, it anchors the sensor tier, feeding aggregated bits to the PM86x processor for logic resolution, while redundancy via dual modules over ring topologies ensures failover transparency in SIL-rated loops. Supported protocols like Modbus RTU allow legacy tie-ins, with built-in supervision flagging open circuits or overvoltages to the system alarm manager, streamlining root-cause mapping without manual polling.

Its intuitive modularity shines in expansions: no proprietary tooling required beyond Compact Control Builder for assignment, and hot-swap capability preserves runtime during maintenance windows. For instance, in a multi-zone batch reactor, banks of ABB UFC911B106 3BHE037864R0106 units can segment inputs by safety class, isolating permissive signals from permissive ones to optimize scan efficiency. This proximal role to the process edge accelerates event capture—often under 1 ms—while vibration-dampened terminals endure panel shakes, preserving contact reliability. Far from a mere passthrough, it enriches the control continuum, distilling field discretes into actionable pulses that synchronize disparate assets, allowing engineers to orchestrate complex flows with the assurance of unerring input fidelity.

- UFC911B106 3BHE037864R0106

- UFC911B106 3BHE037864R0106

| Specification | Details |

|---|---|

| Model Number | 3BHE037864R0106 |

| Brand | ABB |

| Type | Digital Input Module |

| Input Voltage | 24 V DC (18-30 V range) |

| Operating Temp Range | -25°C to +70°C |

| Mounting Style | DIN Rail / S800 Rack |

| Dimensions | 50 x 130 x 120 mm (W x H x D) |

| Weight | 0.4 kg |

| Interface/Bus | PROFIBUS DP, Ethernet/IP |

| Compliance | CE, RoHS, IEC 61131-2 |

| Supported Protocols | Modbus RTU, PROFIBUS |

| Typical Power Draw | 4 W |

Real-World Benefits

Embracing the ABB UFC911B106 3BHE037864R0106 equips your I/O layer with isolation-grade resilience that thwarts common gremlins like inductive kickback from solenoids, ensuring input states hold true across EMI-saturated floors and translating to fewer spurious actuations in sequential machines—teams in bottling lines, for example, report 18% less jam clears from misread limit switches, directly hiking OEE without process tweaks. Its channel-wise diagnostics surface contact welds or wiring faults via heartbeat signals, empowering shift techs to isolate issues at the rack rather than chasing ghosts plant-wide, which curtails escalation tickets and preserves diagnostic bandwidth for value-driven analytics.

The module’s rack-agnostic design further eases evolutionary paths, plugging into existing S800 skeletons with zero reconfiguration, which compresses retrofit timelines and sidesteps the sunk costs of full I/O overhauls in phased upgrades. Over cycles, its wide thermal band and conformal shielding sustain debounce accuracy amid dust or humidity fluxes, obviating frequent recalibrations that erode trust in control narratives— a pharmaceutical mixer outfit noted halved validation runs post-swap, crediting the unit’s IEC-compliant logging for audit agility. Engineered for endurance, it ensures long-term performance by buffering transients that degrade lesser boards, aligning with lean mandates where input uptime mirrors line velocity.

This infusion yields empowered workflows: by streamlining binary feeds to the PLC, operators unlock richer HMI contexts—like animated permissives that intuit bottlenecks—fostering quicker handoffs and reduced training lifts for cross-trained crews. It trims engineering overhead through plug-in templates that auto-map to safety SIL2 loops, while fault-tolerant outputs guard against single-channel dropouts. For those architecting robust DCS, the ABB UFC911B106 3BHE037864R0106 isn’t ancillary hardware—it’s a fidelity forge that distills field chaos into control clarity, amortizing via amplified throughput and the quiet confidence of inputs that just work.

Typical Use Cases

Petrochemical facilities integrate the ABB UFC911B106 3BHE037864R0106 in ESD panels, where it aggregates discrete alarms from pressure switches and solenoid feedbacks to enforce shutdown logics, its isolated channels excelling in explosive atmospheres for high-reliability I/O that meets ATEX directives amid volatile vapors. Continuous uptime imperatives drive its deployment in process control environments, capturing edge events in under 2 ms to preempt overfill cascades.

In food and beverage processing, the ABB UFC911B106 3BHE037864R0106 monitors hygienic sensors on filler lines, debouncing fill-level discretes to synchronize valves without drip risks, engineered to shrug off washdown residues and ensuring critical system uptime per FDA traceability. Fast data cycles support recipe shifts, making it a mainstay in used in packaging plants optimizing throughput sans contamination halts.

Pharmaceutical batching suites employ this module for cleanroom interlocks, polling door status and agitator run signals to gate material feeds, its modular rack fit thriving in sterile corridors with minimal intrusion. Harsh conditions like laminar flows test its seals, but the ABB UFC911B106 3BHE037864R0106 delivers unyielding digital precision, vital for GMP-compliant sequences where input lapses could void lots. Across energy, consumer goods, and life sciences, the ABB UFC911B106 3BHE037864R0106 anchors signal trust, excelling where discrete fidelity fuels seamless automation under regulatory gaze.

Compatible or Alternative Products

UFC912B108 3BHE037865R0108 – Analog output counterpart for balanced I/O in mixed-signal DCS expansions.

UFC718AE101 3BHB003017R0101 – Legacy digital input module for cost-effective retrofits in AC 800M legacy racks.

DO801 3BSE020514R1 – High-density output companion for permissive chaining in S800 I/O assemblies.

DI801 3BSE020512R1 – Similar 16-channel input variant with enhanced SIL3 for safety-critical loops.

UFC911B105 3BHE037864R0105 – Predecessor revision with basic isolation for entry-level process monitoring.

PM861K01 3BSE018157R1 – Hosting CPU for AC 800M integrations, pairing with UFC modules for full control nodes.

SB801 3BSE020513R1 – Binary simulator add-on for offline testing of UFC input configurations.

CI854A 3BSE030221R1 – Profibus interface board for extending UFC connectivity in remote fieldbus drops.

Setup Notes & Maintenance Insights

Prior to slotting the ABB UFC911B106 3BHE037864R0106 into your S800 frame, verify jumper configurations for input types—wet contacts demand external powering, so match to your sensor specs to dodge floating states that mimic opens. Bus addressing is key: assign unique nodes via rotary switches to evade collisions on PROFIBUS segments, and test continuity on isolators with a megohmmeter targeting >1 MΩ barrier resistance, as subpar grounds invite phantom triggers in shared cabinets. Firmware sync counts too—pull the latest from ABB’s vault and flash offline, confirming version parity with the host PM to prevent handshake stalls; allocate 10% headroom on the rack’s power budget, as surges from adjacent actuators can brown out channels.

Day-to-day vigilance keeps it primed with checks that weave into your PM fabric, sidestepping overhauls for steady vigilance. Bi-weekly, eyeball the channel LEDs against a dry-run simulator—uniform greens affirm debounce efficacy, with isolated flickers signaling sticky contacts worth a quick terminal retighten to 0.5 Nm. Semiannually, inject pulse trains via the front test points to benchmark edge detection within 0.5 ms, archiving traces to spot debounce drifts from capacitor aging; this flags proactive board refreshes before they bite into logic timing. In steamy or particulate-heavy bays, swab terminals with isopropyl quarterly to repel conductive films, but mask the PCB to preserve the conformal layer—avoid vacuums that static-zap. Harness Modbus queries monthly for fault accumulator reads, correlating spikes to nearby welders for shielding upgrades. These distilled field notes, born of rack-side realities, position the ABB UFC911B106 3BHE037864R0106 as an unobtrusive operative, channeling scrutiny to process polish over peripheral patrols.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626