Description

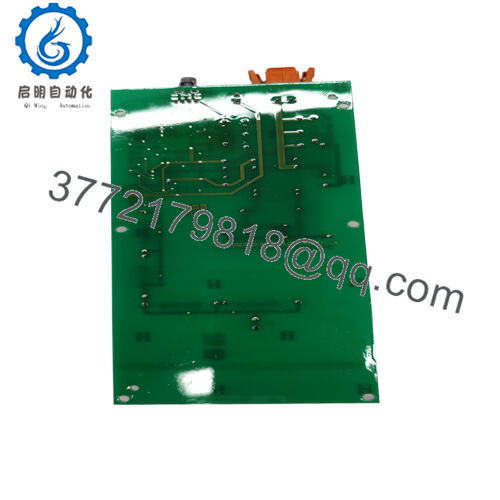

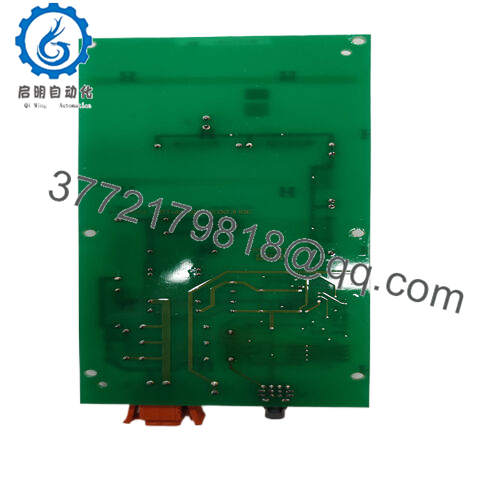

In the high-stakes realm of industrial automation, where communication network failures can cascade into widespread process disruptions, lost production hours, and escalated troubleshooting costs, engineers face the daunting task of pinpointing faults in distributed bus architectures without invasive diagnostics that halt operations or require extensive cabling probes. These challenges are particularly pressing in legacy or hybrid control systems, such as those in power utilities or chemical processing facilities, where open circuits, shorts, or ground faults in fieldbus rings might evade detection amid EMI noise or long cable runs, leading to intermittent data losses that compromise signal reliability and system uptime. The ABB UFC765AE102 3BHE003604R0102 steps in as a dedicated fault-locating indicator (FLI) board for the Advant Master process control system, providing targeted detection and isolation of Masterbus 300 network anomalies to restore integrity swiftly and minimize downtime in demanding environments. Envision a substation bus loop: a subtle ground fault from cable abrasion could fragment controller communications, delaying relay commands and risking overloads, but the ABB UFC765AE102 3BHE003604R0102 monitors for signature fault patterns—such as impedance mismatches or leakage currents—delivering localized alerts via integrated indicators or bus queries to guide pinpoint interventions without full system shutdowns. It’s essential in modular DCS expansions, from retrofitting INFI90-era setups to integrating with S800 I/O in vibration-heavy enclosures, where high reliability ensures compliance with standards like IEC 61158 and reduces the engineering burden of oscilloscope sweeps or loop-back tests. This board fosters proactive network health, supporting goals like enhanced process control and scalability by enabling fault segregation that prevents minor glitches from escalating into major outages. Far from a generic monitor, the ABB UFC765AE102 3BHE003604R0102 empowers teams to maintain resilient backbones, shifting focus from reactive hunts to optimized operations in industrial automation landscapes where bus vitality directly underpins throughput and safety.

The ABB UFC765AE102 3BHE003604R0102 integrates into the diagnostic tier of ABB’s Advant Master distributed control system, functioning as a passive-to-active fault detector that taps into the Masterbus 300 serial ring—typically RS-485-based at 187.5 kbps—to scan for electrical anomalies across segments, then asserts status outputs or interrupts to the host controller for logging and isolation. It slots into standard rack positions alongside bus couplers or I/O modules like the DI810, drawing 24 V DC from the backplane while connecting via screw terminals for tap points or inline insertion, where it employs impedance bridges and current sensors to differentiate faults like opens (high resistance) from shorts (low resistance) or grounds (leakage to earth). In a deployed ring, it might patrol a 1 km loop in a manufacturing cell, flagging a short in a node-to-node cable by lighting segment-specific LEDs and pulsing a fault relay to the AC 800M for automated bypass, preserving token-passing continuity. This supports redundancy through zoned monitoring, where multiple ABB UFC765AE102 3BHE003604R0102 units divide the bus into fault domains for granular resolution in hot-standby configurations. Diagnostics leverage onboard jumpers for sensitivity tuning and Modbus RTU queries over the bus for remote polling of event counters, without proprietary tools, while its galvanic isolation (up to 500 V) shields against transients in noisy bays. Positioned at the network periphery of the I/O architecture, it decouples transient faults—like induced surges—from core communications, ensuring clean data propagation for polling or alarming in rack ecosystems. For legacy blends, the ABB UFC765AE102 3BHE003604R0102 accommodates firmware patches via ABB’s tools, anchoring evolutions from simple rings to meshed fieldbus webs where fault foresight underpins seamless process control.

- UFC765AE102 3BHE003604R0102

- UFC765AE102 3BHE003604R0102

| Specification | Details |

|---|---|

| Model Number | UFC765AE102 3BHE003604R0102 |

| Brand | ABB |

| Type | Fault-Locating Indicator Board |

| Input Voltage | 24 V DC |

| Operating Temp Range | -25°C to +70°C |

| Mounting Style | Rack or Backplane |

| Dimensions | 160 mm x 100 mm x 25 mm |

| Weight | 0.3 kg |

| Interface/Bus | Masterbus 300 |

| Compliance | CE, RoHS, IEC 61158 |

| Supported Protocols | Modbus RTU, Profibus (via bus) |

| Typical Power Draw | 4 W |

Deploying the ABB UFC765AE102 3BHE003604R0102 embeds a network nerve center calibrated for preemptive precision, where its segmented scanning thwarts fault propagations that might otherwise orphan remote nodes, yielding rings that self-localize issues in under 1 second and trim mean-time-to-repair by half compared to blind probes, ideal for 24/7 sites where every minute offline erodes margins. Through prolonged bus vigils, this manifests as diagnostics that surface anomalies like intermittent grounds early, enabling flux adjustments on flux feeds rather than flux firefighting post-blackout.

Its backplane-native fit and jumper-simplicity further lighten retrofit loads, as inline taps hasten ring proofs without cabling overhauls, shortening FAT windows and channeling expertise to topology tweaks over trace tallies in legacy loops. Caretaking sharpens too, with LED-coded zones that cue isolations upfront—via bus sweeps—narrowing audits to zoned verifies and stretching spans betwixt blanket retests, compounding to a slimmer spares slate and amplified bus tenure.

In sum, the ABB UFC765AE102 3BHE003604R0102 nurtures a vigilant vein in bus-burdened industrial automation, where such sentinels not only gird link longevity but also unlock scopes for layered lore, like predictive fault nets on live laps, all unburdened by the tangle of tracer tools or the snares of unquenched quivers.

In utility distribution bays, the ABB UFC765AE102 3BHE003604R0102 patrols Masterbus rings linking RTUs and breakers, where it clinches high reliability amid arc flashes and relay raps, bracing process control environments that bank on fault-free polls for load handoffs in hot grid process control webs.

Chemical fractionation towers harness the ABB UFC765AE102 3BHE003604R0102 for valve bus diagnostics, upholding critical system uptime against vapor veils and pump throbs, with zone clout ensuring telemetry handoffs that nix data drops in continuous distillation process control scaffolds.

Mining ventilation shafts embed the ABB UFC765AE102 3BHE003604R0102 to monitor fan status over long rings, backing fast data cycles under dust devils and draft drags, where its locator poise holds airflow alerts steady and nips stalls in unbroken air process control frames.

UFC718AE101 – Bus interface companion for Advant Master signal buffering.

UFC760AE101 – Communication processor variant for higher-speed ring extensions.

UFC921A101 – Power supply module pairing for stable 24 V feeds in fault zones.

UAA326A04 – Logic I/O add-on for discrete fault relay integrations.

TVB3101-1ISC – Serial gateway module for hybrid protocol bridges.

SPDSI14 – Digital input module benefiting from FLI-protected bus ties.

TC630 – Optical modem for extended fault-tolerant fiber segments.

3BHE003604R0002 – Uncoated variant for non-corrosive indoor applications.

When prepping the ABB UFC765AE102 3BHE003604R0102 for your rack, map tap points to bus segments—ensuring inline insertion doesn’t exceed 10 m spurs—and verify the 24 V DC rail purity with <0.5 V ripple to avert false triggers from supply noise. Scout enclosure seals for IP54 minima in dusty vaults to stay within -25°C to +70°C, routing taps shielded from relay coils, and run a cold-boot self-scan via ABB’s diagnostics to baseline impedance sans live traffic.

Tending it turns on foresight: glean fault counters quarterly o’er the bus to trace recurrence peaks or zone drifts, and reseat taps post-vibration events for contact firmness, as loose ties amplify false opens over runs. Biannual end-to-end mocks with impedance injectors validate detection thresholds under 50 Ω, and a non-abrasive swab of terminals curbs corrosion in humid bays. These observances mold the ABB UFC765AE102 3BHE003604R0102 into a quiet quarrier, unearthing unearthlies ere they unravel rings and cradling your bus’s beat with discerning economy.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626