Description

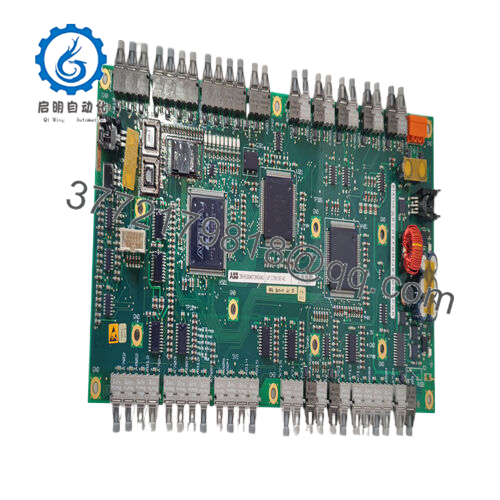

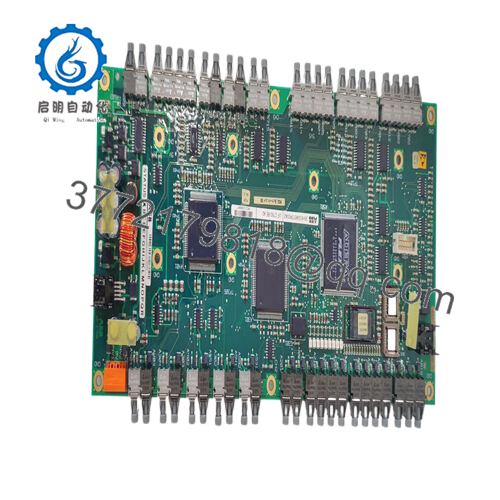

The ABB UFC760BE42 (3BHE004573R0042) interface board is a crucial component widely used in industrial automation systems, especially within distributed control systems (DCS) and programmable logic controllers (PLC). This board is designed to buffer and store data, serving as a vital intermediary that manages communication between CPUs and external devices. It finds extensive applications in industries such as power generation, oil and gas, mining, ports, heating, gas, and water supply systems, where reliable data handling and signal synchronization are paramount. The ABB UFC760BE42 addresses key challenges of maintaining data integrity and smooth communication flow in electrically demanding environments, ensuring control systems operate efficiently under variable load and electrical noise conditions.

This interface board forms part of ABB’s modular automation toolkit, designed to harmonize signal and power management within complex control architectures. It functions as an integration point for digital and analog signals, coordinating data transfer between control elements and the larger automation network. Its compatibility with communication protocols like PROFIBUS DP and RS-485 makes it suitable for control systems requiring robust networking capabilities and high-speed data exchange. The ABB UFC760BE42 fits into industrial cabinets or control panels via a compact form factor supported by DIN rail mounting, facilitating seamless installation in existing setups. Engineers value this board not only for its buffering and data storage capabilities but for how it simplifies integration while enhancing stability and responsiveness of the overall control system.

UFC760BE42 3BHE004573R0042

UFC760BE42 3BHE004573R0042

The ABB UFC760BE42 is built to deliver steady performance in rugged industrial environments. It supports a wide input voltage range, typically from 170 to 260 volts AC, with a nominal power supply around 220 volts, ensuring compatibility with standard industrial power systems. The hardware design emphasizes durability, featuring IP54-rated industrial protection against dust and splashes, making it suitable for challenging factory conditions. With dimensions approximately 150 mm by 100 mm by 25 mm, the board is engineered for space-efficient panel mounting while maintaining accessible terminal points for signal interfacing. Its thermal resistance allows continuous operation in temperature ranges from -25°C to +70°C, ensuring reliability even in extreme climates typical of many industrial sites.

| Parameter | Value |

|---|---|

| Model | UFC760BE42 (3BHE004573R0042) |

| Manufacturer | ABB |

| Product Type | Interface Board |

| Power Supply | 170-260 V AC (Nominal 220 V) |

| Operating Temperature | -25°C to +70°C |

| Mounting | DIN Rail compatible |

| Dimensions | 150 mm (W) x 100 mm (H) x 25 mm (D) |

| Weight | Approximately 1.26 kg |

| Interfaces | Digital I/O, Analog signal interfacing |

| Certifications | CE, IP54-rated industrial protection |

| Communication | PROFIBUS DP, RS-485 |

Related ABB modules complementing the UFC760BE42 include:

ABB UFC760BE1042 – A similar interface board supporting advanced communication and buffering capabilities.

ABB 3BHE004573R1039 – Interface board variant providing additional configuration options.

ABB S800 I/O Modules – Used for extended input/output handling in automation systems integrating UFC boards.

ABB Advant Controller Series – Higher-level controllers that rely on interface boards like UFC760BE42 for signal processing.

ABB DSQC Series Drive Interfaces – Drives and motion control modules compatible with UFC interface boards for total system integration.

Installation of the ABB UFC760BE42 requires ensuring a clean, vibration-free control cabinet environment with sufficient ventilation to prevent overheating. Checking compatibility of power supplies and communication cabling upfront reduces troubleshooting during setup. Proper grounding and shielding practices are essential to mitigate electrical noise, maintaining signal quality. The DIN rail mounting facilitates secure, standardized installation, and allowing easy access for wiring adjustments or future replacements.

Maintenance entails periodic inspection for dust buildup, verification of terminal connections, and monitoring signal quality. Utilizing integrated diagnostics or external test equipment to verify signal integrity can preempt communication faults. Firmware or configuration adjustments might be required for system optimization based on operational feedback. Regular upkeep ensures the system’s smooth operation and helps avoid unexpected downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626