Description

Real-World Use & Application Scenarios

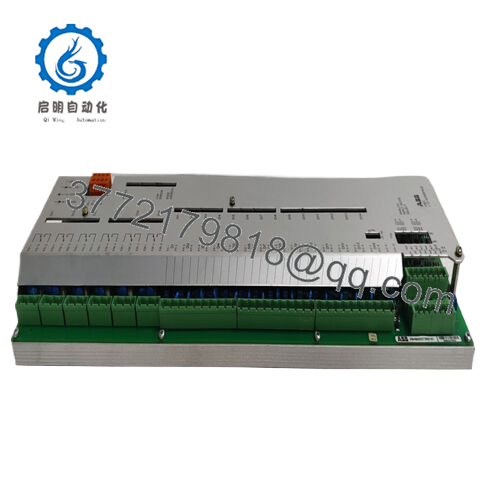

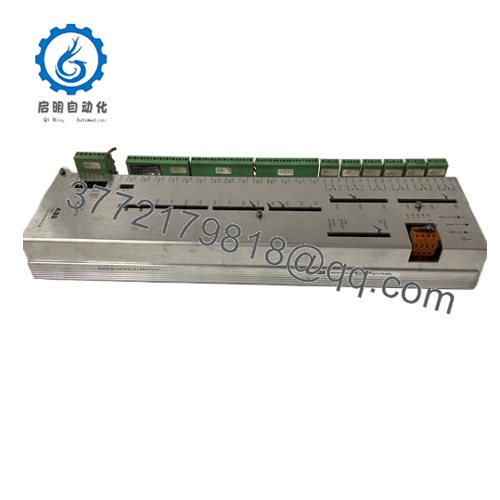

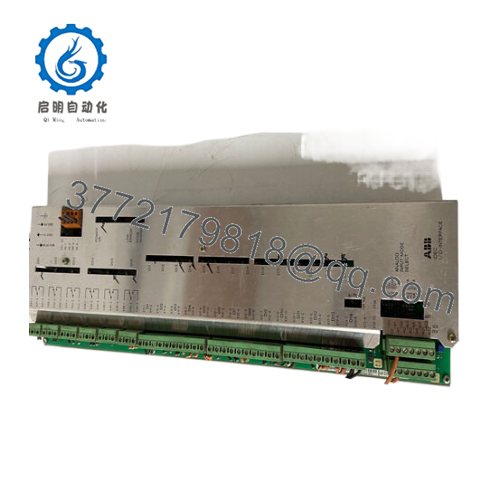

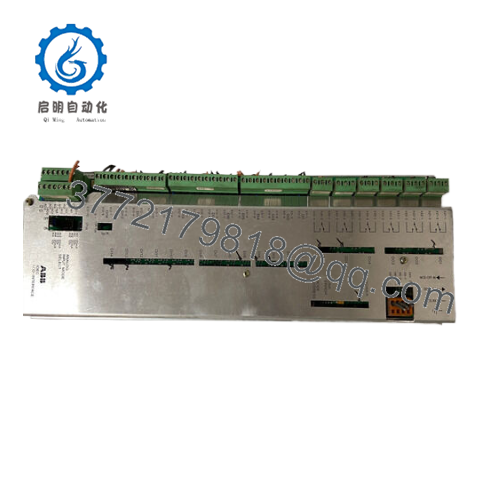

The ABB UFC719AE01 3BHB003041R0001 along with the 3BHB000272R0001 are industrial-grade I/O interface modules widely used in sectors such as manufacturing, energy, and process automation. They support critical automation systems by enabling real-time data exchange between control systems and field devices such as sensors and actuators. These modules help address challenges in complex control environments requiring high reliability, signal integrity, and flexible communication channels within distributed control systems. The UFC719AE01 series is often integrated into ABB’s AC500 PLC family and other automated control platforms, making it essential for efficient process control, remote monitoring, and system scalability.

Product Introduction & Positioning

The ABB UFC719AE01 3BHB003041R0001 3BHB000272R0001 are I/O interface modules designed to provide reliable communication and data handling between programmable logic controllers (PLCs) and connected devices. They offer support for multiple serial communication protocols including RS-232 and RS-485, ensuring versatile connectivity in industrial networks. Positioned as robust interface components within ABB’s automation ecosystems, these modules facilitate precise signal conversion and relay operations. Engineers value these units for their stable performance under harsh industrial conditions and their ability to seamlessly integrate with existing control architectures for effective system expansion and modernization.

Key Technical Features & Functional Benefits

The UFC719AE01 3BHB003041R0001 features high-speed serial communication interfaces supporting protocols like Modbus RTU, enabling effective communication over RS-232/RS-485 networks. It offers multiple digital and analog I/O channels, delivering accurate signal processing critical for process control responsiveness. The module supports reliable data transmission at baud rates typical for industrial automation, ensuring low latency and minimal communication errors.

The hardware design includes rugged construction suitable for industrial environments, with electromagnetic interference (EMI) shielding and stable power regulation. The companion module 3BHB000272R0001 complements these features by expanding I/O handling capabilities or serving similar functions in related systems. Both modules simplify integration within ABB AC500 PLCs and compatible DCS architectures, offering scalability for complex automation tasks.

- UFC719AE01 3BHB003041R0001 3BHB000272R0001

- UFC719AE01 3BHB003041R0001 3BHB000272R0001

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | UFC719AE01 3BHB003041R0001 & 3BHB000272R0001 |

| Brand | ABB |

| Type | I/O Interface Module |

| Communication Protocols | RS-232, RS-485, Modbus RTU |

| Input Voltage | 24 V DC |

| Signal Types | Digital and Analog I/O |

| Baud Rate | Configurable, typical up to 115.2 kbps |

| Weight | Approx. 1.5 kg (UFC719AE01) |

| Operating Temperature | Standard industrial range |

| Mounting | DIN Rail / Panel Mount |

| Certifications | CE, UL, ISO 9001 |

Related Modules or Compatible Units

PM866 – Control CPU module compatible with UFC719AE01 for higher-level processing in modular control systems.

CI854 – Communication interface module supporting fieldbus protocols, complementing I/O modules.

SM811 – Safety CPU module working alongside UFC719AE01 in safety-critical systems.

SPBRC400 – Controller module integrating with I/O interfaces for broader control functions.

SCYC55830 – Trigger pulse board often used in conjunction with I/O modules for signal generation.

Installation Notes & Maintenance Best Practices

Installation of the UFC719AE01 3BHB003041R0001 and 3BHB000272R0001 requires placement within well-ventilated control cabinets to prevent overheating. Proper wiring, grounding, and shielding are essential to maintain signal integrity and minimize electromagnetic interference. Terminals must be securely connected according to ABB wiring diagrams to ensure reliable operation.

Maintenance involves routine cleaning to avoid dust and moisture accumulation, verifying cable connections and functional testing of communication interfaces. Firmware updates recommended by ABB should be applied regularly to ensure compatibility and improve functionality. Using ABB diagnostic software helps monitor module health and facilitate troubleshooting.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626