Description

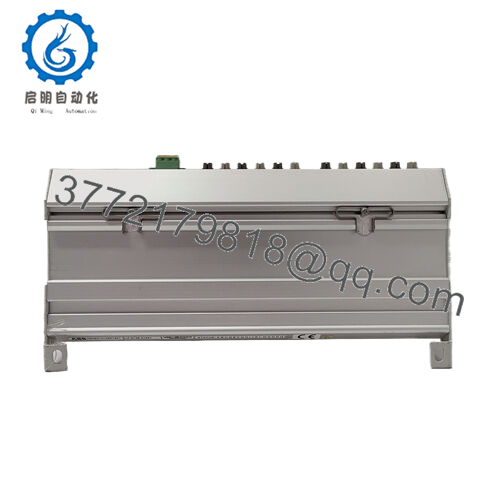

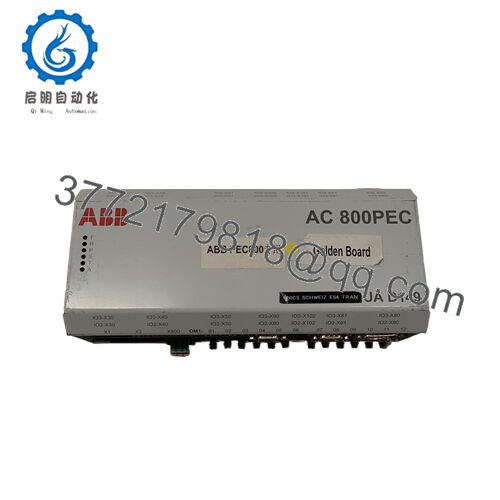

ABB UAD149A1501 3BHE014135R1501 is a powerful digital controller module that is deeply integrated into ABB’s distributed control system (DCS) architecture, especially occupying an important position in the 800xa control ecosystem. In the entire automation architecture, it plays a crucial role as a bridge between the past and the future.

UAD149A1501 3BHE014135R1501

From the perspective of connection with on-site devices, this module can establish communication links with various sensors and actuators conveniently and stably through advanced I/O architecture. For example, analog signals from temperature sensors and digital signals feedback from device switches can be accurately collected by it. The collected data will be efficiently processed within the module, generating corresponding control instructions based on preset control logic, and quickly transmitted to the executing device to achieve real-time control of the production process.

UAD149A1501 3BHE014135R1501

Main features and advantages:

In terms of communication protocols, it demonstrates excellent compatibility and supports multiple mainstream industrial communication protocols such as Modbus and Profibus. This means that in complex industrial environments, regardless of the brand or communication standard of the on-site equipment, ABB UAD149A1501 3BHE014135R1501 can achieve smooth docking, effectively breaking down communication barriers between devices and ensuring collaborative operation between devices within the entire automation system. It is worth mentioning that the module is also equipped with powerful built-in diagnostic functions. During the operation of the system, it can monitor its own running status in real time. Once an abnormal situation is detected, such as hardware failure, communication interruption, etc., it will immediately issue an alarm to the engineer and provide detailed fault information. This greatly shortens the troubleshooting and repair time, effectively reduces the production downtime caused by equipment failures, and provides a solid guarantee for the continuity of enterprise production.

Its outstanding performance ensures high precision in data processing and control in complex industrial environments. In production processes that require almost strict precision, such as precise control of chip etching processes in semiconductor manufacturing and strict proportioning of drug components in the pharmaceutical industry, this module can stably ensure the consistency of the production process, effectively reduce product defect rates, save a lot of production costs for enterprises, and enhance product competitiveness.

This module has excellent anti-interference ability, which enables it to ensure the stability of data transmission and the accuracy of control instruction execution in industrial sites full of complex electromagnetic interference, such as steel smelting workshops, mining areas, etc. It can effectively resist various types of electromagnetic interference, avoid equipment misoperation or data errors caused by interference, and provide reliable guarantees for the safe and orderly operation of the production process. The modular design concept adopted greatly simplifies installation and maintenance work. During the installation phase, engineers can flexibly select and configure corresponding modules based on actual project requirements, significantly reducing the installation and debugging cycle and accelerating project progress. In the later maintenance process, if a module fails, simply replace the faulty module without the need for large-scale adjustments to the entire system, significantly reducing maintenance difficulty and costs, improving the overall maintenance efficiency of the system, and ensuring long-term stable operation of the system

UAD149A1501 3BHE014135R1501

Technical specifications:

Model Number UAD149A1501 3BHE014135R1501

Brand ABB

Type Digital Controller Module

Input Voltage Typically 24V DC

Operating Temp Range -20°C to +60°C

Mounting Style Din rail or panel mount

Interface/Bus Ethernet, supports fiber optic for long – distance communication

Compliance CE, meets relevant industrial standards

Supported Protocols Modbus, Profibus, etc. (varies based on system configuration)

Contact Us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

Application areas:

In the power industry, it is commonly used in the unit monitoring system of power plants. By collecting real-time operating parameters of key equipment such as generators and transformers, such as voltage, current, temperature, and speed, and accurately regulating the equipment based on preset complex control logic, the efficient and stable operation of power production is ensured, the reliable power supply of the power grid is guaranteed, and the continuous demand for electricity in society is met.

In the chemical industry, this module can be applied to core processes in chemical production, such as precise control of temperature and pressure in reaction vessels, and precise adjustment of pipeline flow. The chemical production environment usually faces extreme harsh conditions such as high temperature, high pressure, and strong corrosion, which require extremely high reliability and stability of equipment. ABB UAD149A1501 3BHE014135R1501, with its strong environmental adaptability and excellent data processing performance, can operate stably in such harsh environments, accurately control reaction processes and material transportation, and effectively ensure the safety and product quality of chemical production. In the manufacturing industry, it helps automated production lines achieve efficient collaborative operations between equipment. By real-time monitoring and precise control of various equipment on the production line, such as industrial robots, CNC machine tools, automated conveyor belts, etc., seamless connection of the production process is achieved, the production pace is accelerated, the production efficiency is improved, and the strict requirements for speed and accuracy in large-scale production are met, providing strong support for the intelligent upgrading of the manufacturing industry.

UAD149A1501 3BHE014135R1501

Related products:

ABB UAD149A0001 3BHE014135R0001, As a product in the same series, it has similarities in basic functions with ABB UAD149A1501 3BHE014135R1501, but there may be differences in certain specific functions or performance parameters, making it suitable for application scenarios that are cost sensitive and have relatively basic control requirements. ABB UAD155A0111 3BHE029110R0111 has been enhanced in certain specific functions, such as signal processing speed or control capability for specific types of equipment, making it suitable for complex automation scenarios with higher requirements in these areas and providing users with more targeted solutions.

UAD149A1501 3BHE014135R1501

Installation and maintenance:

Before installing ABB UAD149A1501 3BHE014135R1501, it is necessary to carefully inspect multiple key aspects. Firstly, it is essential to confirm that the on-site power supply is stable and meets the 24V DC input voltage standard required by the module. At the same time, a comprehensive inspection of the power supply lines should be conducted to check for safety hazards such as aging, damage, and short circuits, in order to ensure the continuous reliability of power supply and avoid affecting the normal operation of modules due to power issues. Secondly, it is necessary to accurately verify whether the environmental temperature and humidity at the installation location are within the operating temperature range of -20 ° C to+60 ° C and the corresponding humidity range specified by the equipment. Extreme temperature and humidity environments may cause damage to the electronic components of the module, affecting its performance and service life. For the communication connection part, it is necessary to carefully check whether the network interface is intact, whether the specifications of the selected communication cables (such as Ethernet, fiber optic, etc.) match the equipment interface perfectly, and carefully plan the wiring scheme in advance to ensure that the signal transmission path is not affected by other interference sources, and to ensure the stability and smoothness of data communication. In addition, it is necessary to ensure that the software version of the control platform is fully compatible with ABB UAD149A1501 3BHE014135R1501. If necessary, the control platform software should be upgraded or configured accordingly in advance to ensure seamless integration and collaborative work between the module and the control system.

Regularly checking the LED status indicator lights on the equipment is a simple and efficient method for daily maintenance. By observing the color changes and flashing frequency of the indicator lights, engineers can quickly determine the operating status of the device, such as whether the device is starting up normally, whether the data transmission process is smooth and unobstructed, whether there are hardware failures or software error alarms, etc. Every once in a while, the physical connection parts of the equipment, such as various interfaces, wiring terminals, etc., should be carefully inspected for looseness, oxidation, corrosion, and other phenomena. Once a problem is discovered, it should be promptly tightened, cleaned, or replaced to ensure reliable contact at the connection points and avoid signal interruption or data transmission errors caused by poor contact, which can affect the normal operation of the entire system. It is recommended to conduct a comprehensive functional test on ABB UAD149A1501 3BHE014135R1501 once a year. During the testing process, simulate actual work scenarios, rigorously test key performance indicators such as data acquisition accuracy, control instruction execution accuracy, and communication stability of the equipment, and promptly identify and repair potential problems. Through regular comprehensive maintenance, it is possible to ensure the long-term stable operation of the equipment and provide a solid guarantee for the continuity of industrial production.

Other ABB product models:

ABB 745745

ABB 746376

ABB 07AC91

ABB 07KR31 FPR36000227R1202-O

ABB 07KT92

ABB 07KT92 GJR5250500R0202

ABB 07KT93

ABB 07KT93

ABB 07KT93 GJR5251300R0101

ABB 07KT94 GJR5252100R3261

ABB 07kt94g GJR5252100R0261

ABB 07KT94-S H3 GJR5252100R2201

ABB 07KT98 GJR5253100r0272

ABB 07KT98 GJR5253100R0272

ABB 07KT98 GJR5253100R0272

ABB 07MK92 GJR5253300R1161

ABB 086318-002

ABB 086329-004

ABB 086329-004

ABB 086329-004 includes SMI board (806339-001)

ABB 086339-501

ABB 086345-504

ABB 1KHL178016R0001F PSM03

ABB 1KHL178016R0001F PSM03

ABB 1KHL178016R0001F PSM03

ABB 1KHL178025R0102P COM02

ABB 1KHL178025R0102P COM02

ABB 1KHL178025R0102P COM02

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626