Description

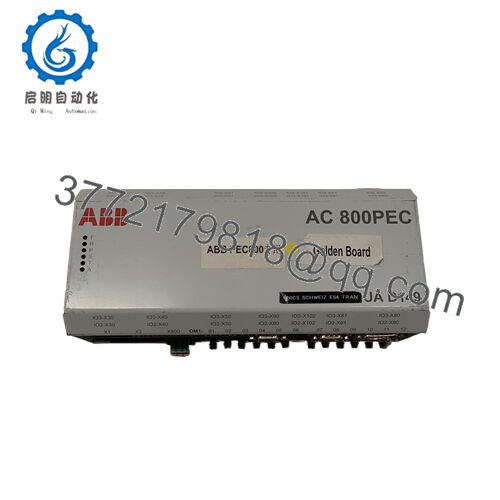

In industrial automation, where voltage instability from grid fluctuations or inductive loads can cascade into erratic drive behaviors, sensor misreads, or outright system lockups, engineers grapple with the imperative to deliver unwavering DC power to control circuits without the overhead of bulky external rectifiers or frequent recalibrations. The ABB UAD149A1501 3BHE014135R1501 meets this demand as a compact power supply module engineered for ABB’s ACS800 variable frequency drive platform, furnishing a steady +24 VDC output to energize logic boards, communication gateways, and signal processors, thereby upholding high-reliability process control in the face of transient disruptions. This module asserts its value in contexts like retrofitting drive cabinets in steel rolling mills or bolstering inverter skids in wind turbine farms, where power sags could derail torque loops or fault isolation, spiking repair cycles and throughput losses. Envision a conveyor synchronization setup in a logistics hub, pulsing under variable motor demands amid harmonic noise from adjacent VFDs—the ABB UAD149A1501 3BHE014135R1501 regulates input variances into pristine rails, forestalling dropout-induced stalls that might jam material flows and trigger safety halts. By anchoring priorities such as modular integration and fault-resilient distribution, it equips teams to forge scalable I/O frameworks that accommodate expansion without rewiring overhauls, tempering the diagnostic burden of intermittent supply faults. For adepts in industrial automation, the ABB UAD149A1501 3BHE014135R1501 is indispensable during evolutions toward decentralized drive architectures, where its wide-range AC/DC input adapts to global grids, preserving signal integrity in EMI-dense enclosures and obviating auxiliary stabilizers. It harmonizes with tenets of sustained loop efficacy, incorporating overcurrent clamps that sequester anomalies before they permeate shared buses, all while dovetailing into ABB’s ecosystem for streamlined commissioning. In core, this module elevates power provisioning from a vulnerability to a virtue, affording you the scope to calibrate dynamic responses over contending with supply specters in stringent process theaters.

The ABB UAD149A1501 3BHE014135R1501 functions by rectifying and stabilizing broad-spectrum inputs—85-264 VAC or 110-370 VDC—into a regulated +24 VDC bus via switch-mode topology with active PFC for ripple attenuation below 100 mV, directly powering auxiliary circuits within the ACS800 drive’s control layer. Positioned as the internal housekeeping source in the drive’s power stack, it slots into dedicated bays on the converter’s chassis, distributing output through low-ESR caps and fused lines to gate drivers, DSPs, and optional fieldbus adapters, ensuring voltage holdup during brief outages without latching the inverter. This integration feeds into the drive’s backplane for seamless handoff to I/O modules like analog scalers or digital interlocks, supporting diagnostics via onboard status relays that signal undervoltage or thermal excursions to the host controller for proactive alerts. In an ACS800 configuration, it complements main rectifier stages by isolating logic from high-voltage domains, bolstering redundancy when paralleled with a secondary unit for hot-standby toggling, and aligns with protocols such as Profibus DP for remote oversight without bespoke interfaces. Efficiency curves peak at 88% under nominal loads, minimizing heat in fanless ops, while no native I/O here—it’s a dedicated feeder—but its rails underpin mixed-signal paths for precise torque vectoring. Consider it sustaining a crane hoist controller: AC mains feed the ABB UAD149A1501 3BHE014135R1501, yielding clean 24 V to the MCU for hoist profiling, all while its EMI filters tame conducted noise from motor cables. This chassis-embedded niche in power hierarchies curtails distribution losses by localizing conversion, enabling you to cascade drives in arrays sans voltage gradients, and redirecting energies toward algorithm honing over housekeeping hassles in multifaceted industrial backplanes.

- UAD149A1501 3BHE014135R1501

- UAD149A1501 3BHE014135R1501

| Specification | Details |

|---|---|

| Model Number | UAD149A1501 (3BHE014135R1501) |

| Brand | ABB |

| Type | Control Power Supply Module |

| Input Voltage | 85-264 VAC / 110-370 VDC |

| Operating Temp Range | -25°C to +70°C |

| Mounting Style | Slot-in / DIN Rail |

| Dimensions | 120 mm x 50 mm x 150 mm |

| Weight | 0.8 kg |

| Interface/Bus | ACS800 Drive Backplane |

| Compliance | CE, UL, RoHS |

| Supported Protocols | Profibus DP (via Drive) |

| Typical Power Draw | 50 W (2.1 A at 24 VDC) |

Adopting the ABB UAD149A1501 3BHE014135R1501 embeds a bedrock of supply constancy that amplifies drive orchestration, as its wide-input tolerance buffers against brownouts that might skew encoder feedback or stall commutation, engendering smoother velocity profiles and curtailing jitter in synchronized axes. Forged for the relentless cadence of automation, it anchors output precision through thermal variances and load transients, which elongates MTBF for embedded roles and simplifies certification trails, restoring bench hours to firmware refinements over drift diagnostics.

The module’s PFC-enhanced conversion trims harmonic draw from upstream grids, easing compliance with IEEE 519 in dense installations and lightening the engineering yoke of filter banks—deploy it in retrofit bays without chassis mods, and you’ve accelerated go-lives while hedging against future grid quirks. Built-in protections like short-circuit foldback further streamline vigilance, piping fault latches to drive logs for swift triage, which condenses outage spans and fortifies availability in regimens where power hiccups mirror production halts.

The essence distills to a fortified drive nucleus: the ABB UAD149A1501 3BHE014135R1501 not merely sustains rails but refines them, channeling unflinching energization that accrues into heightened yields and mitigated exposures for astute engineers.

In metal extrusion presses, the ABB UAD149A1501 3BHE014135R1501 energizes servo amps in ACS800 stacks for ram positioning, weathering inductive rebounds from hydraulic rams to undergird critical system uptime in high-force, cyclic process control environments.

Renewable solar inverters harness it to power MPPT trackers, where the module’s DC input versatility stabilizes gate pulses amid panel shading flux, excelling in outdoor enclosures for peak harvest efficiency in 24/7 grid-tie ops with unwavering reliability.

Textile winding machines integrate the ABB UAD149A1501 3BHE014135R1501 into tension control loops, supplying clean rails for dancer roll sensors under variable speed demands, supporting modular expansions that preserve fast-tension corrections in continuous, humidity-laden production lines.

UAD149A0011 3BHE014135R0011 – Base variant for standard ACS800 frames with reduced output current in lighter-duty applications.

UAD154A 3BHE026866R0101 – Drive control companion module for enhanced processor integration in multi-axis setups.

086370-001 – Analog regulator PWA add-on for bipolar rail extensions from the UAD149 output.

3BHE014135R0101 – Earlier revision with narrower input range for legacy ABB drive migrations.

UAD142 – Auxiliary DC-DC converter for isolated 5 V logic from 24 V bus in embedded controls.

SDCS-PIN4 3ADT314100R1001 – Power interface board for interfacing UAD149 with high-current peripherals.

PFEA112-65 – Excitation adapter for generator tie-ins using UAD149 rails in power systems.

NAIO-03 – Analog I/O expander for scaling UAD149-powered signals in hybrid DCS hybrids.

Before embedding the ABB UAD149A1501 3BHE014135R1501, benchmark your ACS800 bay’s slot pitch and backplane revision to affirm pin compatibility—mismatches can starve adjacent boards—and assay input harmonics against <5% THD to leverage full PFC gains. Provision 5 cm airflow gaps in the chassis, as self-convection falters above 50°C loads, and verify ground bonds at <1 ohm to shunt EMI paths. Cycle power thrice at bench to log startup inrush, tweaking if exceeding 20 A peak.

Caretaking entails quarterly no-load voltage sweeps with a bench supply to nab drift—cap refresh if >1% sag signals aging—and semiannual thermal profiling via IR gun on heatsinks, targeting <60°C rise to preempt derating. For the ABB UAD149A1501 3BHE014135R1501, harvest drive event buffers monthly for supply-related faults, correlating with load logs to pinpoint culprits like cable chafes. A scoped ripple check under full draw annually confirms attenuation, with swaps pegged to 50,000-hour projections. This tactical rhythm, wielding a variac and thermal cam, upkeeps vitality sans major interventions.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626