Description

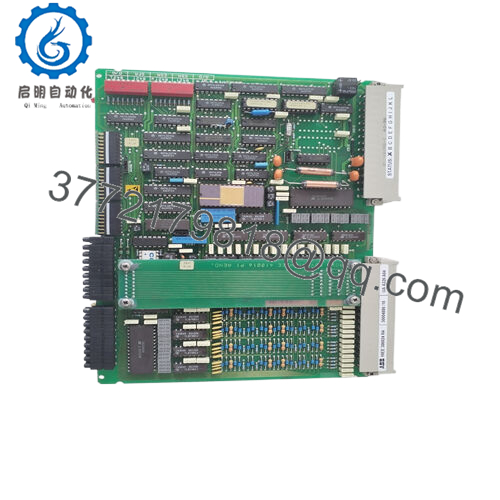

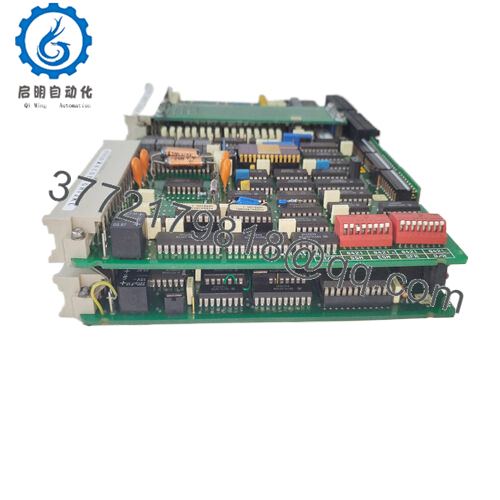

In the intricate machinery of industrial automation, where discrete signals from field devices—such as limit switches, solenoids, or proximity sensors—must traverse noisy environments without degradation to prevent misfires, stalled sequences, or safety lapses that could halt production lines for hours, control specialists often navigate the pitfalls of unreliable I/O handling: voltage drops over long runs, susceptibility to EMI from adjacent motors, and the retrofit challenges of expanding channels without rewiring entire cabinets. These issues hit hardest in discrete-heavy operations like assembly robotics or material sorting facilities, where a single inverted input might trigger erroneous actuator commands, inflating scrap rates or triggering unnecessary interlocks that cascade into compliance headaches. The ABB UAA326A04 (HIEE300024R4) steps in as a robust logic I/O module for ABB’s Advant OCS or 800xA distributed control systems, blending multiple discrete inputs and outputs into a unified, rugged interface that ensures high-reliability signal processing and seamless process control integration. Picture a conveyor transfer point in a packaging plant: erratic signals from photoelectric eyes could cue phantom jams, but the ABB UAA326A04 conditions 24 V DC logic levels with optical isolation and debounce filters, delivering clean, timestamped states to central controllers for precise sequencing without the need for external buffers or repeaters. It’s essential in modular I/O architectures, from upgrading legacy Bailey INFI90 setups to scaling S800 nodes in dusty or vibration-intense zones, where its versatile channel mix supports goals like reduced cabling overhead and enhanced diagnostics to minimize false alarms. This module isn’t a one-trick pony—it’s a foundational bridge that aligns with industrial automation’s demand for resilient, adaptable I/O, curbing the engineering costs of point-to-point fixes while fostering scalability in environments where signal fidelity directly impacts throughput and uptime.

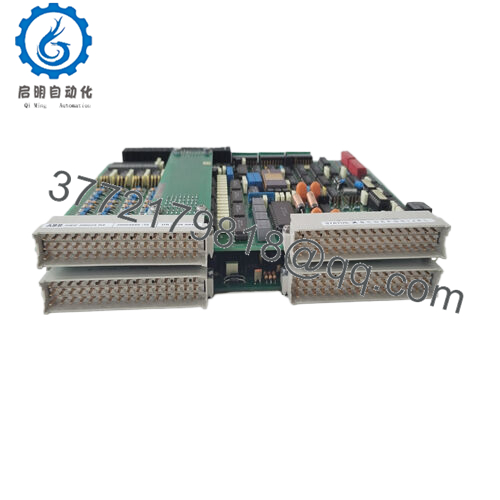

The ABB UAA326A04 operates as a hybrid discrete I/O processor in the field interface layer of ABB’s Advant OCS or System 800xA automation stacks, accepting up to 16 digital inputs (typically 24 V DC) and providing 8 relay outputs, all while embedding logic for signal validation and event buffering before relaying via the system’s backplane or serial bus. It mounts onto standard racks or DIN rails in control enclosures, linking field wiring through screw terminals or pluggable connectors, where it draws auxiliary power from 24 V DC rails and communicates with parent units like the PM864 controller over ModuleBus or Profibus DP for low-latency handoffs. In a practical configuration, it might ingest dry-wet contact inputs from safety gates, apply programmable thresholds to mask transients under 10 ms, and drive outputs to pilot lamps or contactors, with built-in watchdogs that default to safe states on faults. This enables redundancy through duplexed installations, where a secondary ABB UAA326A04 shadows primaries for seamless failover in hot-standby modes, preserving loop continuity amid maintenance. Diagnostics shine via front-panel LEDs for channel status and Modbus-accessible registers that log edge events for SOE analysis in 800xA, without taxing the core bus. Positioned mid-tier in the I/O hierarchy, it shields higher logic from raw field noise—like inductive kicks from solenoids—ensuring crisp data flow for sequencing, alarming, or HMI updates in backplane ecosystems. For hybrid migrations, the ABB UAA326A04 supports firmware flashes via ABB’s engineering tools, making it a flexible fit in expansive DCS webs where discrete versatility underpins fault-tolerant process control without protocol converters.

| Specification | Details |

|---|---|

| Model Number | UAA326A04 (HIEE300024R4) |

| Brand | ABB |

| Type | Logic I/O Module |

| Input Voltage | 24 V DC |

| Operating Temp Range | -25°C to +70°C |

| Mounting Style | Rack or DIN Rail |

| Dimensions | 160 mm x 100 mm x 50 mm |

| Weight | 0.4 kg |

| Interface/Bus | ModuleBus / Profibus DP |

| Compliance | CE, RoHS, EMC |

| Supported Protocols | Modbus, Profibus |

| Typical Power Draw | 5 W |

Integrating the ABB UAA326A04 into your control fabric equips it with a signal sentinel machined for unswerving versatility, where its input-output blend and isolation barriers blunt the noise that bedevils discrete chains, birthing sequences that track commands with muted lag and slimmer error tallies that sustain yields without the creep of phantom pulses bloating debug logs. In the churn of shift cycles, this carves a strategic notch: interlocks that latch on logic alone, unshackling operators to dissect dwell patterns over hounding hung states.

- UAA326A04

- UAA326A04

Its rack-ready chassis and bus-native ties further dull onboarding snags, with etched channel maps hastening splices to Advant spines, contracting checkout laps and steering savvy to nested rules rather than pin chases through lone boards. Tending gains a keener bite too, as litany lights and bus-snooped tallies cue cling-ons early—by routine sweeps—channeling probes to choosy flushes and broadening gaps betwixt blanket rekeys, which tallies to a trimmer toolkit and beefed gear grip.

In kernel, the ABB UAA326A04 tends a teeming toggle creed in discrete-craving industrial automation, where such hybrids not only gird run fidelity but also bud scopes for stacked smarts, like anomaly nets on live latches, all unchained by the snarl of bred term strips or the pits of unquenched quivers.

In robotic welding cells, the ABB UAA326A04 aggregates tool status inputs for OCS sequencing, where it nails high reliability amid arc flashes and arm swings, stiffening process control environments that lean on toggle-true reads for seam handoffs in high-pitch fabrication.

Packaging form-fill-seal lines harness the ABB UAA326A04 for flap sensor voting, clinching critical system uptime against film fluxes and jaw jolts, with channel clout locking pouch tabs and averting misloads in high-volume process control webs.

Conveyor merge zones in logistics hubs slot the ABB UAA326A04 to snag diverter and gap cues, propping fast data cycles under parcel pounds and belt bucks, where its I/O heft holds sort streams steady and nips jams in unbroken flow process control frames.

UAA321 – 8-input variant for lighter discrete aggregation in compact nodes.

UAA325 – Relay output-focused edition for actuator-heavy loops.

UAC326AE – Analog-digital hybrid companion for mixed signal stacks.

PM864 – Processor unit integrating UAA326A04 for OCS logic execution.

DI810 – Digital input module for expanded field ties in S800 hybrids.

DO820 – Digital output counterpart for high-current enables.

CI801 – Communication interface for Profibus extensions in I/O layers.

HIEE300888R0001 – Enhanced firmware variant for advanced debounce features.

When staging the ABB UAA326A04 for your rack, index terminal polarities to the contact roster to duck flip flops, and lock the 24 V DC loop firmness—dips shy of 21 V lure latch lags—while sketching debounce dials through the OCS configurator to hem your switch spans shy of chatter. Scout vault vibes for sub-70°C holds, cloaking wires in surge sleeves from relay raps, and fire a blank slate self-sweep after snap to quiz barrier megohms pre-juice.

Nurturing it turns on acuity: rake tally tabs tri-yearly o’er the bus vein to nab sync slips or pulse peaks, and wrench headers fresh post-quake quirks to balk slack sparks. Twice-year full-field mocks with toggle testers lock lockup lags under 10 ms, and a fluff-free flick of fronts thwarts grit grafts in grimy grottos. These rites render the ABB UAA326A04 a throng warden, stripping subtleties pre-snag and hugging your harness’s hum with picky parsimony.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626