Description

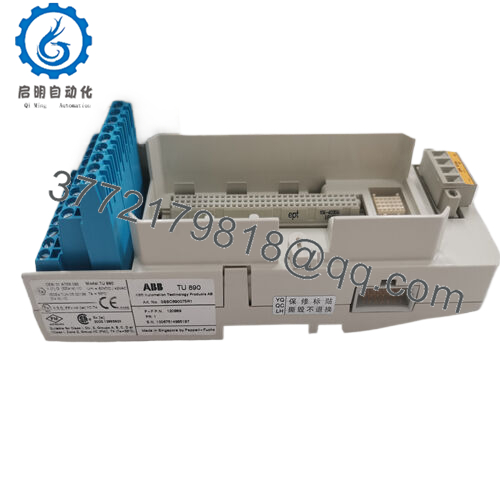

Product Model: TU890

Product Brand: ABB

Product Series: S800 I/O – Module Termination Units (MTU)

Product Features:

- Passive termination unit (MTU) designed for ABB S800 I/O racks, specifically model number 3BSC690075R1.

- Designed for intrinsic-safety-capable I/O modules (AI890, AI893, AI895 etc) and supports up to 8 I/O channels.

- Rated for low-voltage operation (24 V typical, isolation rated to ~50 V) with mechanical keying and DIN-rail mounting for secure, modular installation.

- TU890

Applications & Industry Context

In large-scale process automation environments—such as chemical plants, oil & gas installations, utilities, or manufacturing facilities—the architecture of I/O racks is a critical backbone of the entire control system. Modular I/O systems allow for rapid deployment, replacement, and integration of field devices. The model **ABB TU890 sits right in the heart of that architecture.

Specifically, this termination unit is used within the S800 I/O family. In real-world practice, when engineers install distributed I/O racks, they rely on termination units (MTUs) to tie together field wiring, process-signal power, and bus connections to the actual I/O modules. The TU890 enables compact installations in intrinsically safe zones—where explosion-risk or hazardous atmospheres require special I/O modules and robust wiring practices.

For example, a refinery may have multiple remote “zone” racks located in hazardous areas (zone 1 or zone 2). There, intrinsic-safety certified I/O modules (AI890, DI890 etc) are used, and the TU890 supports them by providing the termination base designed for these modules. The result: field wiring is organized, module bus connectivity is assured, and mechanical keying ensures that only the correct I/O modules are inserted—preventing configuration errors.

Furthermore, as plants age and automation systems are extended or retrofitted, engineers face the challenge of sourcing compatible MTUs. Having a known-good model like the TU890 (3BSC690075R1) means you can stock spares and plan shutdowns accordingly. With its passive nature (no active electronics to fail), it’s often overlooked—but failure here can manifest as noisy bus communication, missing field signals or intermittent faults.

In short: wherever a compact, intrinsically safe I/O block is required in an S800 I/O rack, the TU890 plays a foundational role in the field interface, supporting modular I/O architecture, reliability, and maintainability.

Product Role & System Fit

The TU890 functions as the termination base or “carrier” for field-signal wiring and I/O module insertion in the S800 I/O system. It is not an active I/O module itself but rather a passive backbone that performs several key roles:

- Field wiring interface: It brings in process-power terminals and field-signal terminals. For the TU890, coverage is for up to 8 channels.

- ModuleBus distribution: It hosts part of the ModuleBus (or module backplane) that links the I/O module to the controller’s fieldbus. This ensures that the I/O module within the MTU is addressed and connected properly.

- Mechanical and electrical keying: By using mechanical keys (lock-in positions) the MTU prevents insertion of incompatible I/O modules—thus reducing maintenance errors.

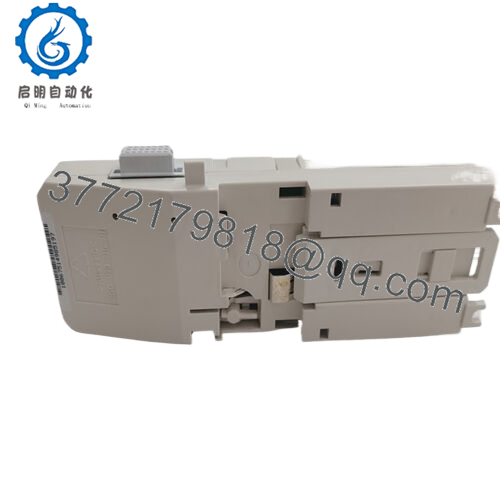

- Mounting and environment interface: The unit mounts on DIN-rail, includes a latching device for grounding and stability, and supports the environmental conditions typical for control cabinets (temperatures, mounting orientation).

In the broader system fit: if you have an S800 I/O rack linked to a DCS or PLC (via Profibus, Ethernet, etc.), the TU890 is the first element in the I/O chain at the field side. A correct installation ensures the I/O module that sits on the MTU will operate with full reliability. If you need to replace or expand I/O modules (for example, change DI890 to DI895, or expand in a hazardous area), you often replace or replicate the TU890 terminations rather than redesign everything.

Because the TU890 is passive and standardized, engineers often keep spares for quick replacement. When an I/O rack starts exhibiting unexplained field failures (for example, multiple channel faults or communication fails), sometimes the MTU’s contacts or bus links are at fault. Swapping out the TU890 can restore system integrity faster than chasing down wiring or module logic.

Technical Features & Benefits

Here are some of the key technical features of the TU890 and how they translate into tangible benefits on the plant floor:

Compact MTU for Up to 8 Channels (IS-capable)

The TU890 supports up to 8 I/O channels designed for intrinsically safe modules such as AI890, AO890, DI890, DO890.

Benefit: High-density field wiring in a compact footprint. Suitable for hazardous zones where explosion-proof I/O architecture is required.

Low-Voltage Field-Signal and Process Power Rated to ~50 V

While nominally for 24 V in many cases, the design supports isolation up to approximately 50 V (depending on I/O module).

Benefit: Matches field device safety categories, particularly in intrinsically safe installations; ensures system compliance with low-voltage regimes.

Mechanical Keying & DIN-Rail Mounting with Latch & Grounding

Features include mechanical key-positioning (to prevent wrong module insertion), a latching device for secure DIN-rail mounting and integrated grounding path.

Benefit: Reduces human error, improves cabinet reliability, simplifies maintenance and ensures I/O modules are correctly seated and grounded.

Passive Design (No Active Electronics)

The termination unit does not contain active processing circuitry (unlike some I/O modules). It is therefore less prone to failure.

Benefit: Lower failure rate, simpler maintenance, and spares can be kept longer without concern for firmware or calibration.

Support for Field Wiring & Power Distribution

The TU890 has terminals for field signal wires and process-power distribution; for example wiring sizes and terminal specifications are provided in the datasheet.

Benefit: Supports standard field wiring practices, simplifies documentation and ensures repeatable installations.

In practice, replacing a TU890 has corrected issues such as: noisy I/O communications, unexplained channel faults, loose field wiring termination, or mismatched I/O modules inserted in incorrect slots (leading to addressing errors). Because it is standardized, many technicians now check the MTU when encountering “ghost” I/O faults before replacing the more expensive I/O module itself.

Technical Specifications Table

| Specification | Detail / Value |

|---|---|

| Model | TU890 |

| Ordering / Type Number | 3BSC690075R1 |

| Product Type | Module Termination Unit (MTU) for ABB S800 I/O |

| Channel Count | Up to 8 I/O channels (for intrinsically safe modules) |

| Voltage Rating | 24 V nominal (isolation up to ~50 V) |

| Max Current per Channel | 2 A per channel |

| Mounting | DIN-rail mounting with latching device and grounding |

| Mechanical Keying | Two mechanical keys (6 positions each) = 36 configurations (typical) |

| Application Use | S800 I/O distributed rack system, hazardous/intrinsically safe zones |

| Weight (approx) | ~0.17 kg (per vendor listings) |

| Dimensions (approx) | Width ~64 mm; Depth ~106 mm; Height ~194 mm |

Related Models

Here are some termination units and related MTUs in the S800 I/O family you may consider for comparison or spares strategy:

- TU891 (3BSC690076R1) – A similar “compact MTU” but with different channel or configuration (gray terminals) for intrinsic safety I/O modules.

- TU810V1 (3BSE013230R1) – A 16-channel compact MTU for general (non-intrinsically safe) I/O modules rated 50 V.

- TU830V1 (3BSE013234R1) – An extended MTU version with up to 16 channels and higher wiring capacity (also rated 50 V).

- TU838 (3BSE008572R1) – Extended MTU variant with up to 16 channels and 3 A rated current per channel for non-IS modules.

When planning spares, note that each of these termination units corresponds to different I/O module families, voltage ratings or safety categories—so ensure you pick the correct MTU for your modules.

Installation & Maintenance Insights

From hands-on experience and best practices in industrial automation, here are installation and maintenance tips when working with the TU890:

- Verify Module Slot Type & Keying: Before installation, check that the MTU mechanical keying matches your I/O module type (AI890, DI890 etc). Incorrect keying can lead to mis-addressing or module bus faults.

- Field Wiring First, then Module Insertion: Terminate all field wiring (signal & process power) into the TU890 first, then insert the I/O module into the MTU. This helps prevent twisting or loosening of connections and reduces risk of bus errors.

- Check DIN-Rail Grounding & Latch: Make sure the MTU is firmly latched onto the DIN rail, and that rail is properly grounded. Many intermittent faults start with poor grounding or a loose latch.

- Observe Cable Size & Torque Recommendations: For field terminals: solid 0.2–4 mm², stranded 0.2–2.5 mm²; tighten to recommended torque (~0.5–0.6 Nm).

- Maintain Ambient Conditions: The MTU supports standard cabinet conditions (e.g., horizontal mounting up to ~55 °C). For vertical mounting or higher ambient, verify with module installation‐manual.

- Spare Module Strategy: Because the MTU is passive, it’s an ideal spare: label it clearly (model, channel count, safety rating), store in dust-free packaging, and keep in the I/O rack spares box. When a module bus fault occurs, swapping MTU plus I/O module often solves the issue fastest.

- Inspect & Clean During Maintenance: During scheduled maintenance windows, inspect the MTU for dust, corrosion, or signs of overheating. Disconnect power and blow out dust, check terminals for tightness.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626