Description

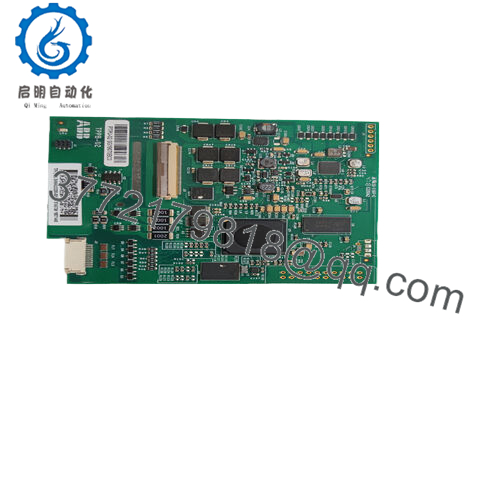

Product Model: TPPB-02

Product Brand: ABB

Product Series: Modular Control / Interface Module (OEM part no. 3HNA023200-001/00)

Product Features:

- High-performance control module designed for industrial automation systems and DCS/PLC integration.

- Supports multi-channel I/O (digital & analog) and communication interfaces (e.g., RS485, Ethernet).

- Designed for durability in harsh environments: wide temperature range, industrial certification.

- OEM part with global aftermarket availability and compatibility with multiple ABB automation systems.

- TPPB-02

Product Role & System Fit

In a modern industrial automation architecture—whether in process plants, manufacturing, utilities or hybrid systems—the link between field instrumentation and control logic is vital. The TPPB-02 module from ABB plays precisely that role: it bridges field devices, control logic, and supervisory systems. When a control system (e.g., DCS or PLC) needs a high-quality, robust control or interface module, this part is often chosen.

Mechanically and electrically, the TPPB-02 is designed to integrate into existing ABB automation frames or racks. With part numbers such as 3HNA023200-001/00 associated, the module is recognized as being compatible in OEM and aftermarket ecosystems. Amikon Limited+1 Whether used as a standalone control board or as part of a larger control cabinet, the TPPB-02 supports the control system’s I/O, communication, and logic-interface requirements.

From the perspective of a system integrator or maintenance engineer: if your plant uses ABB controllers, drives or DCS systems, the TPPB-02 serves as a reliable spare or replacement board. Having one on the shelf means you can respond quickly when a control module fails, thereby reducing downtime and avoiding prolonged system outages.

Applications & Industry Context

The flexibility and robustness of the TPPB-02 make it applicable in a wide range of industrial environments. Here are some typical scenarios:

- Process industries: In chemical plants, petrochemical facilities or refineries where instrumentation (flow, pressure, temperature) must be read and controlled reliably, the TPPB-02 can serve as the module providing I/O channels and control logic.

- Utilities and power generation: In a power plant environment, modules like TPPB-02 are used within control racks monitoring and controlling auxiliary systems, generator controls, or interface applications bridging older and newer systems.

- Manufacturing lines: For machine control, packaging or material handling systems, a reliable control module is critical. The TPPB-02 provides a standard, known platform for such integration.

- Harsh environments: Many industrial sites face vibration, temperature extremes, dust and humidity. Because the TPPB-02 is designed with industrial durability in mind—wide operating temperature range, robust construction—it is well-suited for such conditions.

Having this module in your spare parts inventory is a wise choice in plants where control board failure would cause unacceptable downtime. Engineers often report that replacing a suspect interface/control board with an equivalent high-quality module means the system resumes normal operation faster, with fewer surprises.

Technical Features & Benefits

Here are some of the standout technical features of the TPPB-02 — and how they translate into real-world benefits:

Multi-I/O Support

While exact channel counts vary depending on version, listings describe TPPB-02 modules supporting e.g., 16 inputs / 8 outputs.

Benefit: High channel capacity means one module can handle multiple signals, reducing the number of boards and wiring complexity.

Communication Interfaces

Some versions support RS485, Ethernet, Modbus/Profibus protocols etc.

Benefit: Ensures the module can integrate into diverse networks and connect easily to SCADA or supervisory systems.

Wide Operating Temperature & Rugged Design

Specifications include temperature ranges from –20°C to +60°C and even –40 to +85°C in some listings.

Benefit: Reliable in harsher industrial environments, reduces risk of failure due to ambient conditions.

OEM Brand & Spare Availability

Being an ABB module (part number 3HNA023200-001/00 or 3HNA023200-001/01) implies it is recognized across ABB’s service and parts network.

Benefit: Easier sourcing, consistent performance, fewer compatibility surprises.

In practice, an engineer replacing a failing control board often prefers a unit like the TPPB-02. Its robust design reduces the risk of repeated faults, and many find that after swapping in a fresh unit, the system’s behavior returns to normal quickly.

Technical Specifications Table

| Specification | Detail / Value (typical) |

|---|---|

| Model | TPPB-02 |

| Manufacturer | ABB |

| Ordering / Part Numbers | 3HNA023200-001/00, 3HNA023200-001/01 |

| Module Type | Modular Control / Interface Module |

| Typical Input Channels | 16 inputs (varies by version) |

| Typical Output Channels | 8 outputs (varies by version) |

| Communication Interfaces | RS485, Ethernet, Modbus, Profibus (some versions) |

| Auxiliary / Supply Voltage | 24 V DC (some listings) |

| Operating Temperature | –20 °C to +60 °C (others –40 to +85 °C) |

| Certifications / Ratings | CE, UL (in some product listings) |

| Suitable Applications | Industrial automation, process control, DCS/PLC systems |

| Typical Warranty | 12 months (for new units) |

Related Models

When planning spares or system upgrades, it’s useful to know modules related to the TPPB-02:

- ABB TPPB-02 variant with suffix /01 (3HNA023200-001/01) – same module variant.

- ABB 3HAC029924-004 TPPB-02 – alternate part code listed in some catalogues. Xiongba Automation+1

- Modules of similar role: Control interface boards in ABB’s automation lineup, possibly under different numbering (for example boards in DCS systems).

- When upgrading, compare performance, channel counts and communication options to ensure replacement covers required signals.

Installation & Maintenance Insights

From a hands-on engineering viewpoint, here are practical tips for installing or maintaining the TPPB-02:

- Wiring Check: Before insertion, verify all field wiring is correctly terminated and labelled. Given its multi-channel capacity, mis-wiring is a common source of faults.

- Proper Grounding & Supply: Ensure the module’s supply voltage is stable and within specification. Poor supply can lead to logic faults or I/O errors.

- Cooling and Cabinet Conditions: While the module supports wide temperature ranges, adequate cooling, ventilation and avoiding direct sun or heat sources prolong lifetime.

- Spare Module Strategy: Keep a tested TPPB-02 module in your spares inventory, pre-configured if possible. Given its versatility, replacement is simpler when you have one ready.

- Firmware/Revision Check: If there are multiple variants (–001/00 vs –001/01), verify that spare matches the revision expected by your system. Compatibility is key.

- Post-Installation Verification: After mounting, run diagnostics or build-in test routines to verify channel operation, communication integrity and no unexpected errors.

- Log Module Details: Record the module’s part number, revision, installation date, slot location, and any associated channel mapping. Good documentation helps future troubleshooting.

Following these practices ensures the TPPB-02 module will deliver reliable performance and simplifies maintenance in industrial systems.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626