Description

Real-World Use & Application Scenarios

The ABB SPNPM22 is a network processing module designed to enhance communication efficiency and system integration within ABB’s distributed control systems (DCS), particularly the Bailey Infi 90 system. It is widely used in industries such as power generation, oil and gas, chemical processing, and water treatment plants where complex process data management and control coordination are essential. The SPNPM22 provides seamless Ethernet network connectivity, facilitating real-time data exchange, alarm management, and event monitoring. This module is ideal for environments requiring distributed control architecture, enabling optimized performance and reliable inter-module communications within large-scale automation systems.

Product Introduction & Positioning

The ABB SPNPM22 serves as the backbone network processing module in ABB’s Bailey Infi 90 DCS, responsible for bridging control modules with Ethernet-based communication networks. It supports critical system functions including data aggregation, network routing, and communication protocol management such as Modbus TCP/IP. This module allows distributed control tasks across multiple system nodes to be synchronized efficiently and reliably. Positioned as a key enabler of intelligent control infrastructure, the SPNPM22 promotes system scalability and enhances real-time responsiveness, supporting operators and engineers with improved visibility and control over complex automation processes.

Key Technical Features & Functional Benefits

The SPNPM22 features an Intel Pentium III (or higher) processor coupled with up to 1 GB RAM and a 40 GB hard drive, providing powerful data processing and storage capabilities. Its operating system is based on Microsoft Windows NT 4.0 or newer, ensuring robust software compatibility and performance. Equipped with Ethernet network connectivity, the module enables fast, reliable communication while managing alarms, events, trending data, and system diagnostics. The compact and energy-efficient design minimizes cabinet space requirements and power consumption, which are critical considerations in industrial control environments.

This module supports complex control algorithms and distributed operations, facilitating workload distribution and synchronization across networked control modules, thus optimizing system performance. Its comprehensive diagnostic tools and real-time system monitoring capabilities help minimize downtime and maintenance efforts, making it a vital component in mission-critical control applications.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | SPNPM22 |

| Brand | ABB |

| Type | Network Processing Module |

| Processor | Intel Pentium III or higher |

| Memory (RAM) | Up to 1 GB |

| Storage | 40 GB Hard Drive |

| Operating System | Microsoft Windows NT 4.0 or higher |

| Communication | Ethernet (Modbus TCP/IP supported) |

| Dimensions (approx.) | 160 mm x 160 mm x 120 mm |

| Weight | 0.8 kg |

| Power Consumption | Low |

| Application | Distributed Control Systems, DCS |

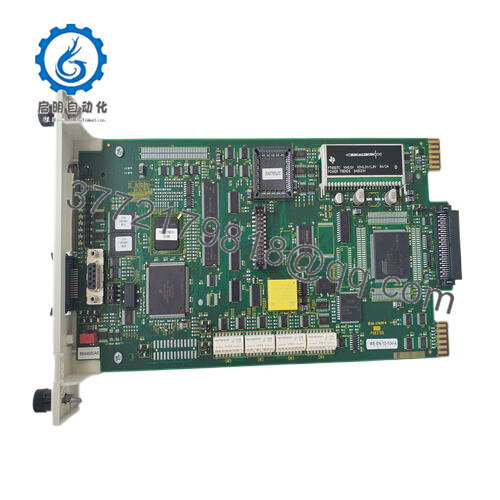

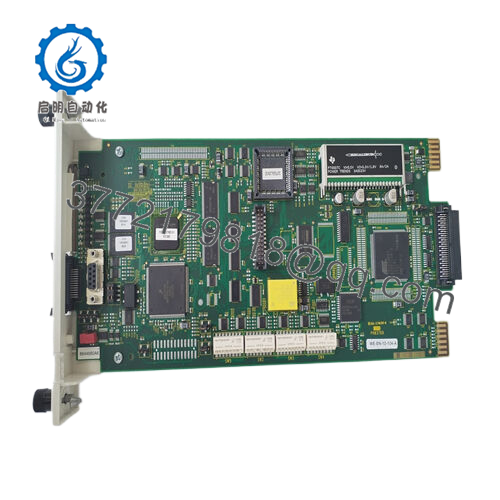

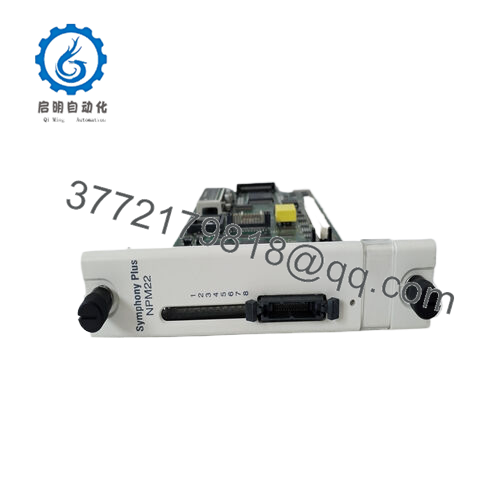

SPNPM22

SPNPM22

SPNPM22

Related Modules or Compatible Units

SPBRC400 – Controller module complementing SPNPM22 for high-level process control.

Harmony Rack Input/Output Modules – I/O modules that integrate with SPNPM22 for extensive automation capability.

SPBRC200 – Earlier generation control module compatible within ABB DCS architectures.

CI853 – Communication interface module often used alongside network processing modules.

Installation Notes & Maintenance Best Practices

The ABB SPNPM22 should be installed in well-ventilated control cabinets to ensure proper heat dissipation and maintain optimal operating temperature. Secure mounting within standard industrial racks is recommended for easy access and system integration. Proper grounding and cabling practices must be observed to prevent electromagnetic interference and ensure reliable communication.

Maintenance includes regular inspection of communication interfaces, firmware updates, and monitoring system diagnostics to detect potential issues early. Utilizing ABB’s diagnostic software allows operators to maintain system health and optimize network performance. Ensuring updated backups and documentation further supports efficient maintenance and rapid recovery if needed.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626