Description

Real-World Use & Application Scenarios

The ABB SPIET800 is an Ethernet CIU (Controller Interface Unit) Transfer Module widely used in industrial automation environments where reliable, high-speed communication is essential. It is commonly applied in chemical plants, power generation facilities, water treatment plants, and manufacturing industries to bridge INFI-NET controllers with host computers over Ethernet networks. This module efficiently supports critical data transmission in supervisory control and data acquisition (SCADA) systems, building automation, and other industrial communication networks. The SPIET800 ensures seamless data exchange, enabling real-time monitoring and control across complex industrial systems, thus addressing challenges of interoperability, data integrity, and system uptime.

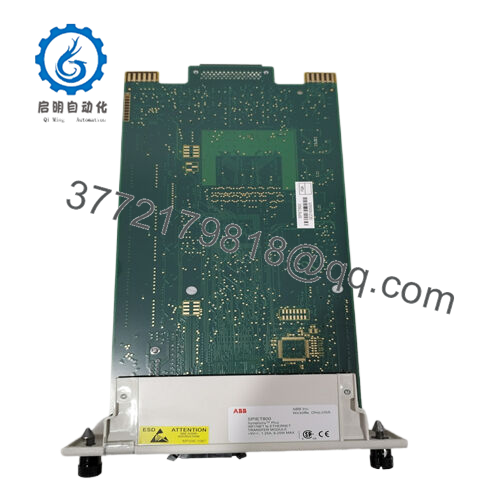

Product Introduction & Positioning

The ABB SPIET800 acts as a high-performance Ethernet CIU Transfer Module that facilitates communication between ABB’s INFI-NET controllers and host systems using TCP/IP over Ethernet. It functions as a bridge that organizes, sorts, and stores data received from control modules before forwarding it reliably to host computers for processing. Positioned within the ABB Symphony Plus control system platform, the module enhances network connectivity and data accessibility, supporting modern automation architectures where high-speed, stable communication is paramount. Engineers incorporate the SPIET800 to ensure robust network integration, increasing operational efficiency and simplifying system architecture.

- SPIET800

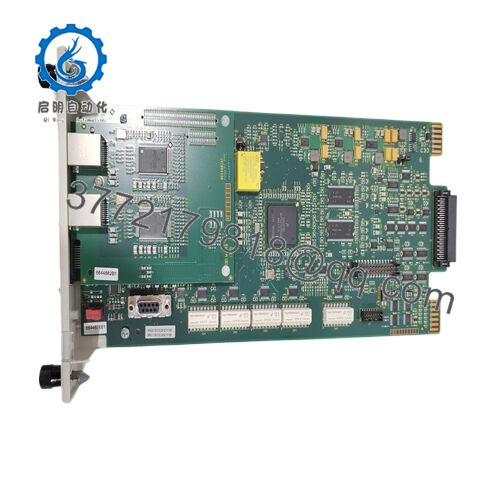

Key Technical Features & Functional Benefits

The SPIET800 features 24 V DC power input with low consumption (~20 W) and operates within a broad temperature range (-20°C to +70°C) suitable for demanding industrial environments. It supports data transfer rates up to 1 Gbps, enabling rapid and stable data flow necessary for real-time process control. The module includes embedded diagnostic functions to quickly identify and solve network and communication issues, reducing downtime. Its compact size and DIN rail or panel mounting provide installation flexibility in industrial control panels.

Advanced security measures such as 128-bit encryption and authentication protect data integrity during transmission, ensuring secure communications in critical infrastructure. The module supports multiple industrial communication protocols, including Modbus TCP/IP, Profinet, DeviceNet, EtherCAT, and Profibus, further enhancing system compatibility and network integration.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | SPIET800 |

| Brand | ABB |

| Type | Ethernet CIU Transfer Module |

| Power Supply | 24 V DC (±10%) |

| Power Consumption | Approximately 20 W |

| Processor Frequency | 25 MHz |

| Communication Speed | Up to 1 Gbps |

| Operating Temperature | -20°C to +70°C |

| Mounting | DIN Rail / Panel Mounting |

| Dimensions (W x H x D) | Approx. 144 x 80 x 35 mm |

| Weight | Approx. 300 g |

| Security Features | 128-bit encryption, authentication |

| Supported Protocols | Modbus TCP/IP, Profinet, DeviceNet, EtherCAT, Profibus |

Related Modules or Compatible Units

IET800 – INFI-NET Ethernet interface module compatible with SPIET800 for network expansions.

SPBRC400 – Control module complementing SPIET800’s communication capabilities.

CI534 – Communication interface supporting interoperability with ABB control systems.

SPNPM22 – Network processing module used alongside SPIET800 in distributed control systems.

REF542PLUS – Protection relay integrating into systems using SPIET800 for data transmission.

Installation Notes & Maintenance Best Practices

Install the ABB SPIET800 in well-ventilated control cabinets to prevent overheating and to maintain reliable performance. Ensure proper grounding and shielding of Ethernet cables to minimize electromagnetic interference and ensure data integrity. Follow ABB’s wiring and installation guidelines to guarantee compatibility and safety. The compact design allows easy mounting on standard DIN rails or inside control panels.

Maintenance involves regular inspection of connectors and cables, firmware updates, and monitoring embedded diagnostic logs to preempt communication issues. Applying ABB’s recommended software updates ensures compatibility with evolving network protocols and security standards. Periodic testing of data throughput and network diagnostics maintains operational reliability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626