Description

SPHHSS13 Product Description:

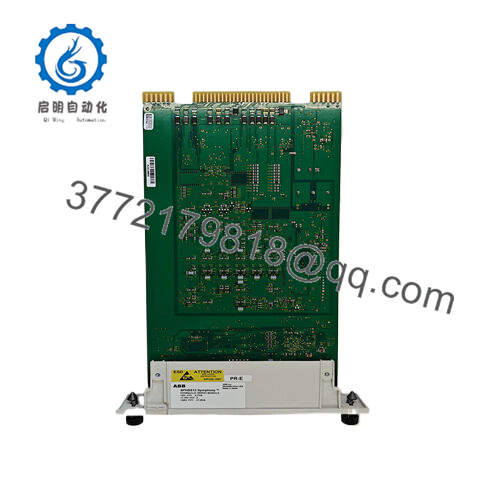

ABB SPHSS13 is a safety shutdown module that is part of the ABB SafetyBuilder M platform, which is a leading solution for creating SIL 3 certified safety instrumented systems. Functionally speaking, it serves as an intelligent interface between on-site safety devices (such as emergency stop buttons, safety valves) and safety controllers, providing signal conditioning, diagnosis, and fault safety switching functions.

SPHSS13

In the security system architecture, ABB SPHSS13serves as a critical node in the security loop, ensuring that analog and digital signals from field devices are processed with zero delay and transmitted to the controller in their complete state. Its dual channel design (channel A and channel B) has independent power and signal paths, ensuring fault tolerance: if one channel detects a fault, the other channel will remain in control to prevent misoperation or dangerous faults from not being detected. For integrators, its value lies in reducing wiring complexity: each module supports up to 8 safety inputs/outputs, has configurable relay outputs, and can directly drive actuators such as solenoid valves or motor circuit breakers.

The uniqueness ofABB SPHSS13 lies in its compatibility with ABB Safety Tool software, which supports graphical configuration of safety logic and automatic generation of Safety Requirements Specification (SRS). This eliminates the need for manual coding, reduces human errors in security critical applications, and accelerates the authentication process.

SPHSS13

Main features and advantages:

SIL 3 Compliance and Diagnostic Function

SPHSS13 meets the Safety Integrity Level 3 (SIL 3) of IEC 61508 standard, with a diagnostic coverage rate (DC) of 99.5% for hazardous faults. Its built-in self-test program continuously monitors the health status of the channel, including voltage levels, relay contact resistance, and circuit continuity. Faults are marked by LED indicator lights and transmitted to the safety controller for proactive maintenance and shortened mean time to repair (MTTR). For example, if there are signs of wear on the relay contacts, the module will trigger an alarm before the contacts fail, preventing potential safety circuit failures.

Robust hardware design

ABB SPHSS13 adopts an IP20 protection level housing installed with DIN rails (can be upgraded to IP65 through external kits), which can withstand harsh industrial environments, including temperature ranges of -40 ° C to+70 ° C, vibrations of 10-500 Hz, and impact loads of 15 g. Its isolated power supply (24 V DC) and surge protection (1.2/50 µ s waveform) can prevent transient spikes in industrial power networks, while the dual winding relay ensures fault safe operation (normally closed when power is off). The compact external dimensions (100mm high x 25mm wide x 160mm deep) optimize the space utilization in the safety cabinet, which typically requires multiple modules in complex systems.

Flexible I/O configuration

All 8 channels ofABB SPHSS13 can be configured as analog inputs (4-20 mA), digital inputs (dry contacts), or digital outputs (relay contacts), supporting mixed signal types in a single module. For analog inputs, it provides 16 bit resolution and hardware filtering functionality to reduce noise generated by motors or transformers. The digital output adopts a high side switch with overload protection function, which can drive loads up to 2 A (250 V AC/30 V DC), suitable for directly driving small valves or alarms.

Scalable system integration

ABB SPHSS13 can seamlessly integrate with ABB SafetyBuilder M controllers and standard AC 800M I/O racks, supporting hybrid safety/non safety systems. It supports Profibus DP V1 security protocol (FBP) to ensure deterministic communication with the security controller, with a data transmission rate of up to 12 Mbps. For large-scale projects, multiple SPHHS13 modules can be networked to enable engineers to build scalable safety systems for facilities such as refineries or offshore platforms, which typically require hundreds of safety loops.

SPHSS13

Technical specifications:

ModelABB SPHSS13

Brand ABB

Type Safety Shutdown Module (SIL 3)

Power supply 24 V DC (19.2-28.8V), supporting redundancy

Working temperature -40 ° C to+70 ° C

Installation method: DIN rail (compatible with S800 I/O rack)

Dimensions 100 mm (height) x 25 mm (width) x 160 mm (depth)

Weight 0.25 kg

8 configurable channels (AI/DI/DO)

Signal type AI: 4-20 mA; DI: Dry contact (normally open/normally closed); DO: Relay (2 A, 250 V AC/30 V DC)

Certified IEC 61508 SIL 3, IEC 61511, ISO 13849-1 PL e, ATEX (Zone 2)

Diagnostic coverage rate (DC) 99.5% (for hazardous faults)

Communication Profibus DP V1 (FBP), 12 Mbps

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

SPHSS13

Application areas:

In industrial environments, safety and reliability are crucial, and lABB SPHSS13, as a critical Safety Instrumented System (SIS) module, is widely used in high-risk areas such as oil and gas, chemical processing, and power generation to protect personnel, assets, and the environment. This module performs well in scenarios that require fail safe emergency shutdown (ESD) functionality, such as controlling overpressure in refining towers, detecting tank leaks, or ensuring safe shutdown of nuclear grade equipment.

Taking liquefied natural gas (LNG) terminals as an example: lABB SPHSS13 can be integrated with on-site sensors (such as flame detectors, pressure transmitters) to monitor process variables in real-time. In the event of critical faults such as methane leakage or sudden temperature rise, it will immediately trigger a shutdown program, isolate the affected system, and activate safety barriers to prevent catastrophic accidents from occurring. In chemical plants, it serves as the core component of safety instrumented circuits, ensuring compliance with the IEC 61511 standard and providing millisecond level deterministic response time even in environments with high electromagnetic interference (EMI).

The reason why engineers choose lABB SPHSS13 is that it simplifies the design of safety systems while maintaining strict standards. For example, in pharmaceutical facilities that produce hazardous compounds, the dual channel architecture and built-in diagnostic function of this module ensure that the safety circuit remains effective during maintenance, reducing downtime for Safety Integrity Level (SIL) verification. Its compact design and hot swappable functionality make it an ideal choice for retrofitting old systems, especially in situations where space is limited and uninterrupted operation is required.

Related products:

SPHSS12- Low Channel Version (4-channel), suitable for small safety systems, is an ideal choice for retrofitting old equipment.

SPHHS14- High density module (16 channels), suitable for large-scale SIS applications, commonly used in petrochemical plants.

The safety controller module of PM866AK01- AC 800M serves as the processing core coordinated with SPHHS13 module.

TB836-SPHHS13 terminal block accessory with quick release connector, can reduce wiring time by 40%.

SPAOI23- Safe Analog Input/Output Module, suitable for systems that require continuous process variable monitoring.

RIO830- Remote I/O coupler, used for expanding secure networks through fiber optics (up to 10 km), compatible with distributed SPHHS13 settings.

SPABUS11- Bus coupler module, used to connect the SafetyBuilder M system to a standard Profibus network for data exchange with non secure domains.

Installation and maintenance:

Precautions before installation

Safety circuit design: Lay safety signal cables in dedicated conduits marked as “safety only” to avoid electromagnetic interference (EMI) from non safety cables. For analog signals, use shielded twisted pair cables and terminate the shielding layer in the control cabinet to prevent grounding loops.

Configuration verification: Before powering on, use ABB Safety Tool to simulate safety logic and verify the response time of critical circuits (such as ESD activation within 50 ms). Ensure that all channels are correctly assigned to safety functions according to the Safety Requirements Specification (SRS).

Redundancy setting: In SIL 3 applications, the ABB SPHSS13 module is deployed using a 1oo2D (one out of two with diagnostics) configuration, and hardware redundancy is used to meet the safety indicators of low demand mode.

maintenance agreement

Monthly functional testing: Use certified testing tools to simulate fault conditions (such as injecting a 21 mA signal to trigger an over range alarm) and verify that the module responds correctly. Record test results for compliance review.

Firmware management: Update firmware annually through Safety Tool to incorporate the latest safety algorithms and patches. Test updates in an offline simulation environment before deploying to the production environment.

Component wear monitoring: Use a magnifying glass every quarter to check for signs of arcing or corrosion on the relay contacts. Replace excessively worn modules to maintain fault safety functionality.

Other product models of ABB brand:

ABB UFC933A101 3BHE048062R0101

ABB A0650 3BHT300051R1

ABB SPS01 2VAA008278R001

ABB SPS03-5V 2VAA008280R001

ABB SPS03-15V 2VAA008281R001

ABB BP01-L 2VAA008282R101

ABB BP01-R 2VAA008282R301

ABB BP-K01-AA 2VAA008284R101

ABB MVR 0.80-10KA 800V AC/1000V DC

ABB GFD233A103 3BH022294R0103

ABB PM856AK01 3BSE066490R1

ABB SW-190148

ABB 560PSU02 1KGT011900R0001

ABB AFC094AE02

ABB UAD149A0011 3BHE014135R0011

ABB 3BHE014135R0011

ABB PFVL 141C DIM.D=810 3BSX670292-112

ABB 5SHY3545L0014 3BHE023784R0001

ABB 1TGE120021R001

ABB PM904F

ABB PCD231

ABB HIEE300661R0001 UPC090AE01

ABB FMT200-ECO2

ABB 3BHB040253R0001

ABB SC520M 3BSE016237R1

ABB REC670 1MRK004814-AG

ABB TGM5 P14436-1072510

ABB GOP2000

ABB GOP2010

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB XUD194 XUD194A 3BHC018137R0001

ABB XV5628A

ABB Y129740-002

ABB YPI105C

ABB YPK112A 3ASD573001A13

ABB YPO104

ABB YPP-105F(YT204001)

ABB YPP110

ABB YPQ110A

ABB YPQ110A 3ASD573001A5

ABB С-093H

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626