Description

Real-World Use & Application Scenarios

The ABB SPBRC410 controller is widely employed in industrial automation environments where reliable communication and advanced process control are essential. Frequently found in industries such as power generation, chemical processing, oil and gas, and manufacturing, this controller facilitates seamless integration and control of complex automation systems. It is designed to handle real-time control tasks, data acquisition, and communication, making it a crucial component in distributed control systems (DCS). The SPBRC410 addresses challenges related to scalable system architecture, network interoperability, and efficient data management across large industrial installations.

Product Introduction & Positioning

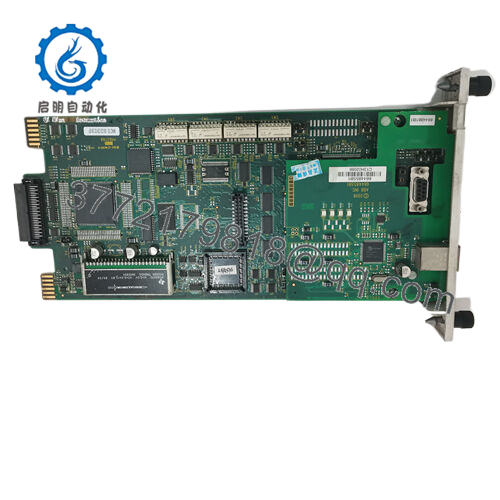

The ABB SPBRC410 is a high-performance bridge controller within ABB’s Symphony Plus family, designed to enhance communication between Symphony Plus and legacy Bailey Infi 90 systems. It acts as a communication gateway, enabling smooth interoperability and data exchange across different generations of control platforms. Equipped with a Modbus TCP interface, the module supports modern Ethernet communication protocols, facilitating integration with a wide range of industrial networks. Positioned as a versatile and compact control processor, the SPBRC410 provides industrial engineers with a scalable solution for system upgrades, modernization, and improved operational efficiency.

Key Technical Features & Functional Benefits

The SPBRC410 features a robust microprocessor (e.g., MCF5475 ColdFire® 32-bit) with clock speeds around 256 MHz to handle demanding control and data processing tasks. It includes 4 MB of ROM, 64 MB of RAM, and 2 MB of non-volatile RAM to ensure high storage capacity and reliable performance. The controller supports multiple communication ports including a 10/100 Mbps Ethernet port and RS-232 serial ports, accommodating diverse network and device connectivity. Its compact design (approximately 178 mm x 51 mm x 330 mm) allows easy installation in standard control racks or panels.

The device supports up to 30,000 function blocks, offering extensive control flexibility for complex process automation tasks. Integrated diagnostics and redundant communication options enhance system reliability and facilitate maintenance. The SPBRC410 is compliant with international standards, supporting industrial operating temperature ranges and environmental resilience crucial for long-term deployment.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | SPBRC410 |

| Brand | ABB |

| Type | Symphony Plus Bridge Controller |

| Processor | MCF5475 ColdFire® 32-bit, ~256 MHz |

| Memory | 4 MB ROM, 64 MB RAM, 2 MB NVRAM |

| Communication Ports | Ethernet 10/100 Mbps, 2x RS-232 serial ports |

| Supported Function Blocks | Up to 30,000 |

| Power Supply | 24 V DC (±20%) |

| Operating Temperature | 0 to +70°C (forced ventilation recommended) |

| Dimensions (LxWxH) | 330 mm x 51 mm x 178 mm |

| Weight | Approx. 0.3 kg |

| Compliance | ISO 9001, CE |

Related Modules or Compatible Units

SPBRC400 – Earlier generation bridge controller with similar capabilities and architecture.

PM866 – High-performance processor module integrated with ABB Symphony Plus systems.

CI853 – Communication interface enabling network protocol conversions.

SPNPM22 – Network processing module complementing bridge controllers in DCS.

Harmony Rack I/O Modules – Expand I/O capabilities in systems using SPBRC410 controllers.

SPBRC410

SPBRC410

Installation Notes & Maintenance Best Practices

Install the ABB SPBRC410 securely in industrial control racks ensuring proper ventilation to prevent overheating, especially considering the recommended forced cooling for higher temperature ranges. Grounding and EMI protection measures are critical for maintaining signal integrity. Follow ABB’s detailed wiring and mounting instructions to ensure stable operation and easy access for maintenance.

Regular maintenance includes firmware updates to support evolving communication standards and security enhancements. Perform periodic functional testing through the device’s diagnostic interfaces to ensure system health. Monitor memory status and power supply voltages as part of routine preventive maintenance to prevent unexpected failures.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626