Description

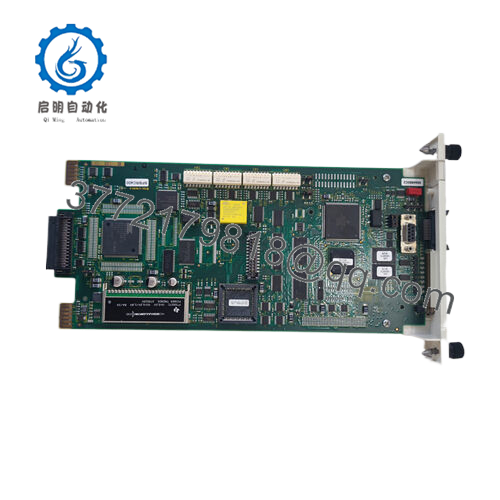

ABB SPBRC400 Product Description:

ABB SPBRC400 is a high-performance protocol bridge controller belonging to the Harmony Plus industrial automation solution series, designed for scalability and interoperability. As part of the ABB AC 800M control system ecosystem, it serves as a neural interface between heterogeneous networks, enabling bidirectional data exchange between protocols such as Profibus DP, Modbus RTU, and Ethernet/IP.

SPBRC400

Functionally, ABB SPBRC400 acts as a transparent gateway, located at the intersection between on-site devices and high-level monitoring systems. Its architecture supports up to 16 simultaneous communication channels, allowing engineers to configure complex routing rules, such as aggregating data from over 50 Modbus sensors into a Profinet frame and transmitting it to the SCADA system. For system integrators, its value lies in reducing hardware usage: one SPBRC400 can replace multiple single protocol gateways, simplify panel design, and reduce energy consumption.

Its uniqueness lies in its compatibility with ABB Control Builder software, which provides drag and drop mapping functionality across protocol data points. This eliminates the need for underlying programming and enables junior engineers to deploy complex integration workflows. Whether used for standalone devices or distributed control systems (DCS), SPBRC400 ensures seamless flow of control commands and diagnostic data between different network architectures.

SPBRC400

Main features and advantages:

Protocol flexibility and performance

ABB SPBRC400supports over 20 industrial protocols, including legacy standards such as CANopen and modern IIoT protocols such as MQTT. Its PowerPC 604e CPU (1 GHz) and 512 MB RAM can achieve real-time data conversion of less than 10 milliseconds, which is crucial for delay sensitive applications such as high-speed packaging lines. The built-in error handling mechanism, such as cyclic redundancy check (CRC) verification and heartbeat monitoring, ensures data integrity even in susceptible networks.

Robust industrial design

TheABB SPBRC400 adopts an IP65 rated housing installed with DIN rails, which can withstand harsh environments including 10-500 Hz vibration, 15 g impact, and extreme temperatures from -20 ° C to+60 ° C (expandable to+85 ° C when forced cooling). Its isolated power supply (24 V DC) and surge protection (1.2/50 µ s waveform) can prevent voltage spikes in industrial power grids, which is common in large motor load factories. The compact exterior dimensions (358 mm high x 272 mm wide x 71 mm deep) optimize the space inside the congestion control cabinet, while the front LED indicator provides intuitive updates on network connectivity and module health status.

Scalable Integration and Security

This module supports up to 1000 data points per channel and is suitable for large-scale applications such as smart cities or refineries. For environments that prioritize security, it provides configurable firewall rules and TLS 1.2 encryption based on Ethernet protocol to ensure compliance with Industry 4.0 network security standards. Its hot swappable design allows for maintenance without interrupting the system, which is crucial for 24/7 production facilities as downtime means revenue loss.

Long term reliability

The mean time between failures (MTBF) of ABB SPBRC400 exceeds 200000 hours, and ABB offers a 10-year lifecycle support commitment to ensure its long-term durability. Its fanless design reduces mechanical wear, while advanced thermal management ensures stable operation even in enclosed cabinets. Through ABB Ability ™ The cloud platform regularly updates firmware to add new protocol support and optimize performance, enabling investments to withstand constantly changing industry standards.

SPBRC400

Technical specifications:

ModelABB SPBRC400

Brand ABB

Type Protocol Bridge Controller

Power supply 24 V DC (19.2-28.8V), isolated, redundant

Working temperature -20 ° C to+60 ° C (expandable to+85 ° C when forced air cooling)

Installation method: DIN rail (TS35/7.5 or TS35/15)

Dimensions 358 mm (height) x 272 mm (width) x 71 mm (depth)

Weight 0.5 kg

Interface 2x Ethernet (10/100 Mbps), 2x RS-485, 1x USB 2.0, PROFIBUS DP/V1

Supported protocols include Profibus, Modbus RTU/TCP, Ethernet/IP, OPC UA, MQTT, CANopen, DeviceNet

Certified CE, UL, CSA, IEC 61131-2, IEC 61000-6-2/-6-3, ATEX (Zone 2)

Cooling method: Thermal conduction (passive), optional fan kit for high temperature environment

Data throughput up to 1000 I/O points per second

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

SPBRC400

Application areas:

In industrial environments, seamless integration between different systems is crucial, andABB SPBRC400has become a key task-based bridge controller in hybrid automation architectures. This module is designed specifically for industries such as automotive manufacturing, food and beverage processing, and intelligent infrastructure, solving the problem of unified management of legacy and modern devices in complex control networks.

For example, when upgrading robot welding equipment in an automotive assembly plant, the ABB SPBRC400 can connect old-fashioned PLCs based on PROFINET and new robot arms using Ethernet/IP protocol, converting protocol differences in real-time to ensure synchronous motion control. In water treatment facilities, it can connect Modbus RTU based flow meters with the entire plant OPC UA monitoring system to achieve centralized monitoring of chemical dosing systems while maintaining compatibility with legacy on-site equipment. In pharmaceutical factories, protocol conversion functionality is equally crucial to ensure compliant connectivity between FDA compliant batch control systems and predictive maintenance platforms driven by the Internet of Things (IoT).

Engineers deploy ABB SPBRC400 to eliminate “automation islands” and avoid data flow stagnation and productivity decline caused by system incompatibility. For example, in a steel plant, it can connect the decades old DeviceNet network that manages blast furnace sensors with advanced Industrial Internet of Things (IIoT) platforms, enabling real-time heat map data to support predictive maintenance algorithms. By reducing the reliance on custom coding for protocol conversion, this module can reduce integration costs by up to 40% in multi vendor environments, making it an ideal solution for brownfield transformation and green space projects.

SPBRC400

Related products:

SPBRC300- Low cost version with 8 communication channels, suitable for small to medium-sized systems that require basic protocol conversion.

SPBRC500- High end model, equipped with dual core CPU and 1 GB RAM, designed specifically for ultra-low latency applications such as robotics and motion control.

PM866AK01- AC 800M CPU module, integrated with SPBRC400 as the control core to achieve unified automation logic.

TB836-RS-485/Profibus connection terminal block adapter simplifies on-site wiring and reduces installation time by 30%.

CI854AK01- Profibus DP master/slave interface module, often used in conjunction with SPBRC400 for hybrid Profibus Ethernet networks.

DI810 3BSE018170R1- Digital Input Module, used for integrating binary signals, in conjunction with SPBRC400, suitable for systems that require mixed signal types.

RIO830- Remote I/O coupler, extends communication network through fiber optic (up to 10 kilometers), compatible with distributed SPBRC400 settings.

CM602- The communication module of ABB drives enables SPBRC400 to interface with variable frequency drives in the conveying system.

Installation and maintenance:

Precautions before installation

Network topology planning: Plan protocol conversion requirements before installation to ensure that SPBRC400 is located at the network boundary (e.g. between field devices and control rooms). Pre configure data mapping using ABB Control Builder to reduce on-site debugging time.

EMC compliance: Separate Ethernet and Profibus cables from power conductors to avoid electromagnetic interference (EMI). In hazardous areas, use certified intrinsically safe isolation barriers for on-site connections.

Power redundancy: Deploy redundant power supplies (such as ABB PS501) for SPBRC400 in critical applications to prevent downtime caused by transient power loss.

maintenance agreement

Monthly Health Check: Use the module’s web interface to view error logs and protocol specific diagnostics (e.g. Profibus frame errors). Verify the LED status indicator to ensure network activity and power stability.

Firmware update: via ABB Ability ™ The platform updates its firmware every quarter to ensure access to new protocol drivers and security patches. Test updates in a simulated environment before deploying to the production network.

Annual system review: Conduct a comprehensive review of data mapping and routing rules to ensure they meet current operational requirements. Use compressed air to clean the dust from the ventilation openings of the chassis to maintain thermal efficiency.

Other product models of ABB brand:

ABB UFC933A101 3BHE048062R0101

ABB A0650 3BHT300051R1

ABB SPS01 2VAA008278R001

ABB SPS03-5V 2VAA008280R001

ABB SPS03-15V 2VAA008281R001

ABB BP01-L 2VAA008282R101

ABB BP01-R 2VAA008282R301

ABB BP-K01-AA 2VAA008284R101

ABB MVR 0.80-10KA 800V AC/1000V DC

ABB GFD233A103 3BH022294R0103

ABB PM856AK01 3BSE066490R1

ABB SW-190148

ABB 560PSU02 1KGT011900R0001

ABB AFC094AE02

ABB UAD149A0011 3BHE014135R0011

ABB 3BHE014135R0011

ABB PFVL 141C DIM.D=810 3BSX670292-112

ABB 5SHY3545L0014 3BHE023784R0001

ABB 1TGE120021R001

ABB PM904F

ABB PCD231

ABB HIEE300661R0001 UPC090AE01

ABB FMT200-ECO2

ABB 3BHB040253R0001

ABB SC520M 3BSE016237R1

ABB REC670 1MRK004814-AG

ABB TGM5 P14436-1072510

ABB GOP2000

ABB GOP2010

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB XUD194 XUD194A 3BHC018137R0001

ABB XV5628A

ABB Y129740-002

ABB YPI105C

ABB YPK112A 3ASD573001A13

ABB YPO104

ABB YPP-105F(YT204001)

ABB YPP110

ABB YPQ110A

ABB YPQ110A 3ASD573001A5

ABB С-093H

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626