Description

Real-World Use & Application Scenarios

The ABB SPBRC400 controller with expanded memory is widely used in industrial automation systems requiring advanced control, monitoring, and reliability. This controller finds applications in process industries such as chemical, power generation, oil and gas, and manufacturing plants where real-time operations and data processing are critical. The SPBRC400 is designed to address challenges around process control accuracy, system integration, and reliable operation under demanding conditions. Its enhanced memory capacity and processing power make it suitable for complex supervisory and control tasks across distributed control systems (DCS) and programmable logic controller (PLC) platforms commonly used in industrial automation.

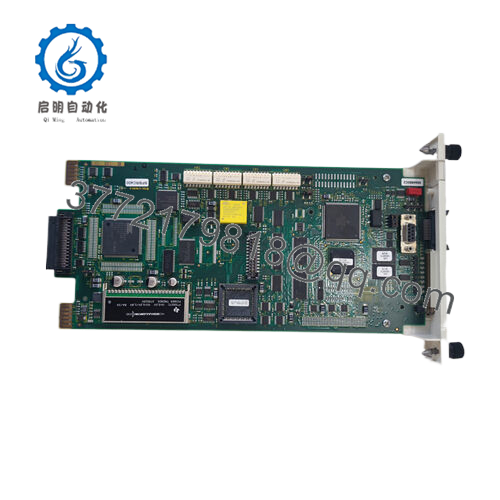

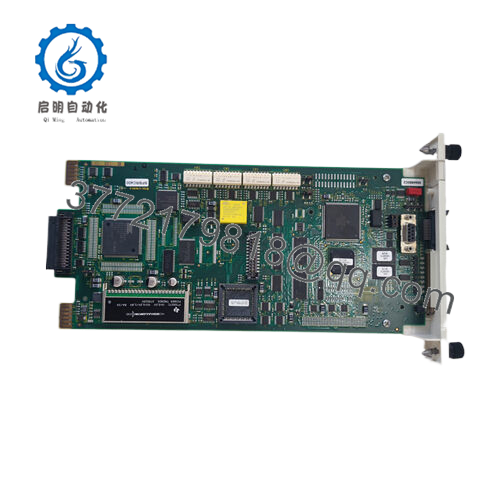

Product Introduction & Positioning

The ABB SPBRC400 is a high-performance controller module within ABB’s Symphony Plus series that offers expanded memory and processing capabilities. Positioned as an upgrade to previous controller generations, this device supports advanced control algorithms, extensive data logging, and real-time diagnostics, ensuring control system responsiveness and reliability. It fits seamlessly into ABB’s Harmony Rack control system architecture, serving as a backbone module that executes control strategies and manages communication with field devices. Engineers appreciate the SPBRC400 for its scalability, flexibility, and robust design, which enable its use in both greenfield projects and modernization of existing automation systems.

Key Technical Features & Functional Benefits

The ABB SPBRC400 boasts a high-speed processor that significantly outperforms previous versions, offering near real-time Boolean logic execution with enhanced program memory and data storage capacity. It supports multiple communication protocols, allowing integration with a wide range of industrial networks and devices. The controller is equipped with advanced diagnostic tools that provide predictive maintenance insights and real-time status updates, reducing unplanned downtime and maintenance costs.

- SPBRC400

Its hardware design emphasizes durability and compactness, with a lightweight form factor enabling easy integration into control cabinets and racks without compromising ventilation or accessibility. The SPBRC400 also features fault-tolerant capabilities and self-monitoring functions that ensure continuous system operation, making it suitable for mission-critical industrial environments demanding high availability.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | SPBRC400 |

| Brand | ABB |

| Type | Controller with Expanded Memory |

| Processor | High-performance (exact speed not publicly specified) |

| Memory | Expanded program and data memory |

| Communication | Multi-protocol support |

| Dimensions (L x W x H) | Approx. 358 mm x 71 mm x 272 mm |

| Weight | Approx. 0.5 kg |

| Mounting | Rack or panel mount |

| Environmental Rating | Industrial environments |

| Diagnostic Features | Real-time diagnostics, predictive maintenance support |

Related Modules or Compatible Units

SPBRC410 – Controller with similar architecture offering additional input/output capabilities.

Harmony Rack Modules – Various input/output and communication modules compatible with the Symphony Plus series.

SPBRC200 – Earlier generation controller module with lower memory capacity.

SPBRC500 – Advanced controller module designed for more extensive automation tasks.

CI854 – Communication interface modules that can be paired with SPBRC400 for network integration.

Installation Notes & Maintenance Best Practices

Installing the ABB SPBRC400 requires secure rack or panel mounting in well-ventilated control cabinets. Proper cable management and grounding are essential to avoid signal interference and ensure reliable communication. The controller’s compact size allows it to fit into standard industrial racks with straightforward connectivity to peripheral devices.

Maintenance should focus on regular inspection of connectors, firmware updates, and monitoring diagnostic reports to prevent unexpected failures. The built-in self-monitoring features provide early warnings of potential faults, enabling preventive maintenance. ABB recommends periodic software and firmware updates to maintain compatibility with evolving network protocols and automation system enhancements.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626