Description

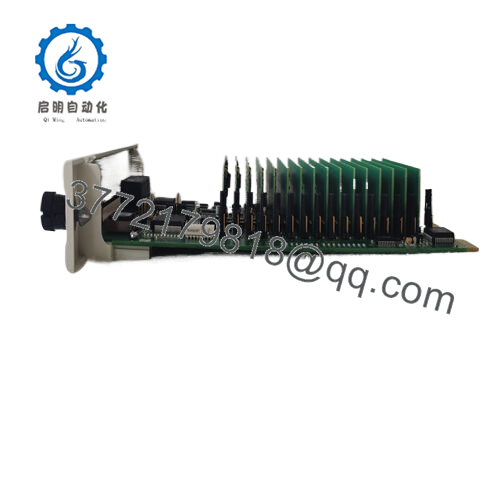

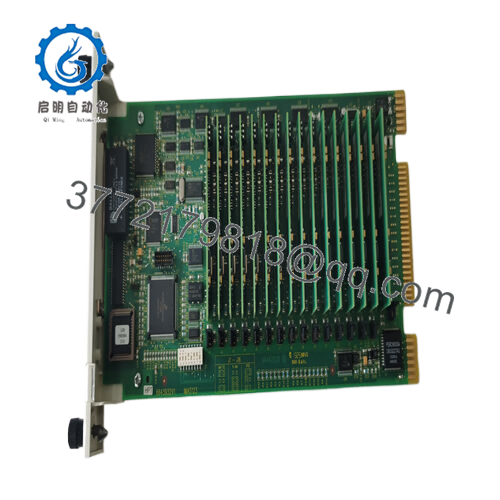

SPASI23 Product Description:

ABB SPASI23 is a safety input/output interface module designed specifically for ABB’s SafetyBuilder M system, which is a leading platform for creating fault safe automation solutions. As a member of the AC 800M control system family, this module serves as a bridge between discrete safety field devices and safety controllers, capable of transmitting binary signals (such as “safety” or “alarm”) while strictly isolating from standard I/O channels.

SPASI23

The core function of this module is to enhance system integrity through hardware diagnostics and redundancy design. Each channel is equipped with independent power and signal paths to ensure that faults in one channel do not propagate to other channels – this is a key design in SIL 3 applications. For engineers, its value lies in reducing the complexity of safety circuit wiring: ABB SPASI23 supports normally open (NO) and normally closed (NC) contacts, making it compatible with a wide range of field devices without the need for rewiring. Its compatibility with ABB Safety Tool software allows for configuring safety logic through a graphical interface without the need for underlying programming, thereby speeding up debugging.

Unlike general security modules,ABB SPASI23 has been optimized for high channel density applications. In a compact DIN rail installation form, it provides 24 configurable input/output points, maximizing the use of panel space in space constrained facilities such as offshore oil platforms or compact food processing lines.

SPASI23

Main features and advantages:

SIL 3 Compliance and Diagnostic Function

ABB SPASI23complies with the IEC 61508 SIL 3 standard and has a diagnostic coverage rate (DC) of over 99% for critical faults. Its built-in self-test program continuously monitors channel resistance, voltage levels, and loop continuity, and marks open or short circuits through LED indicator lights and system alarms. This proactive fault detection can shorten the mean time to repair (MTTR) and ensure that the safety system remains in an effective state throughout its entire lifecycle.

Robust hardware design

This module adopts reinforced isolation barriers to provide 2.5 kV AC voltage isolation between channels and system grounding, protecting against transient surges in industrial power networks. Its wide operating temperature range (-40 ° C to+70 ° C) and anti vibration capability (10-500 Hz) make it suitable for harsh environments such as steel plants or mining operations, where standard electronic equipment may fail prematurely.

Flexible I/O configuration

All 24 channels of ABB SPASI23can be individually configured as secure inputs or outputs through software, providing flexibility for various applications. For input channels, it supports dry contacts (such as mechanical switches) and solid-state signals (such as 24 V DC proximity sensors). The output channel includes a fault safety relay with a switching capacity of 2 A, which can drive solenoid valves or motor starters in emergency shutdown (ESD) scenarios.

Scalable system integration

This module can seamlessly integrate with ABB’s SafetyBuilder M controller and standard AC 800M I/O rack to achieve hybrid safety/non safety systems. It supports Profibus DP V1 (FBP) with secure configuration files, ensuring deterministic communication in safety critical networks with data transfer rates up to 12 Mbps. For large-scale projects, multiple ABB SPASI23 modules can be connected in series, allowing engineers to build scalable security systems without sacrificing performance.

SPASI23

Technical specifications:

ModelABB SPASI23

Brand ABB

Type safe I/O interface module, 24 channels (configurable I/O)

Power supply 24 V DC (19.2-28.8V), with redundant power supply capability

Working temperature -40 ° C to+70 ° C

Installation method: DIN rail installation (compatible with ABB S800 I/O rack)

Dimensions 100 mm (height) x 50 mm (width) x 160 mm (depth)

Weight 0.4 kg

Signal type input: dry contact (NO/NC), 24 V DC; Output: Relay (2 A, 250 V AC/30 V DC)

Certified IEC 61508 SIL 3, IEC 61511, ISO 13849-1 PL e, ATEX (Zone 2), CE, UL

Diagnostic coverage rate (DC) 99% (critical faults)

Communication Profibus DP V1 (FBP), 12 Mbps

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

SPASI23

Application areas:

In high-risk areas of industrial automation, safety, accuracy, and scalability are essential elements, and the lABB SPASI23 safety interface module has become a key component in complex process control systems. This module is designed specifically for industries such as chemical manufacturing, pharmaceutical production, and heavy machinery to connect safety related field equipment (such as emergency stop buttons, safety switches, and pressure relief valves) to Safety Instrumented Systems (SIS).

Taking a pharmaceutical factory that produces life-saving injections as an example, the lABB SPASI23 module serves as a neural connection between sterile processing equipment and a safety programmable logic controller (PLC), ensuring that a fail safe response is immediately triggered in the event of any deviation from preset safety parameters, such as pressure surges or unauthorized entry into a clean room. It adopts a dual channel architecture and built-in diagnostic function, which complies with the IEC 61508 SIL 3 standard. It is indispensable in applications where system failures may cause environmental hazards, production losses, or personnel injuries. On the automotive assembly line, this module can monitor the safety light curtain and protective fence of the robot unit, achieving seamless integration of the safety circuit and the overall automation network, while strictly isolating from non safety control signals.

The engineer chose the lABB SPASI23 module because it can simplify security system design in a distributed environment. Whether renovating old equipment or deploying new automated production lines, its hot swappable design and intuitive configuration can reduce downtime during maintenance or expansion. By centrally processing security signals, this module helps manufacturers meet ISO 13849-1 PL e compliance requirements, reduce liability risks, and ensure regulatory approval in the global market.

SPASI23

Related products:

SPAOI23- Safety Analog Input/Output Module, used to integrate continuous process variables (such as temperature, pressure) into safety circuits, typically paired with SPASI23 in hybrid systems.

SPADI23- Safe Digital Input Module (16 channels), suitable for high-density binary signal applications, is an ideal choice for numerous safety interlocks in large machinery.

SPAOO23- Safety output module (8-channel, relay), used to drive actuators in ESD systems, complementary to SPASI23 in fault safety control circuits.

PM866AK01- The safety controller module of AC 800M, as the processing core, executes safety logic based on the input of SPASI23.

TB836- The wiring terminal accessory of SPASI23 has plug and play connection function, reducing wiring errors during installation.

RIO830- Remote I/O interface, used for expanding secure networks (up to 10 kilometers) through fiber optics, compatible with distributed SPASI23 installations.

SPABUS11- Bus coupler module, used to connect the SafetyBuilder M system to a standard Profibus network, enabling data exchange between secure and non secure domains.

SPASIM23- Simulation module, used to test the configuration of SPASI23 in a controlled environment, reducing risks during debugging.

Installation and maintenance:

Considerations before installation

Safety circuit design: Separate the wiring of safety signal cables from non safety cables to prevent electromagnetic interference (EMI). Use dedicated cable trays or trunking marked as’ safety only ‘to maintain functional safety integrity.

Grounding: Connect the protective grounding (PE) and signal grounding (SG) of the module to a single point grounding system to avoid grounding loops. For facilities with explosive atmospheres, ensure that all connections comply with ATEX’s inherent safety guidelines.

Configuration verification: Before powering on, use ABB’s Safety Tool software to verify channel allocation and safety parameters. Test logic sequences using built-in simulation mode without activating on-site devices.

maintenance agreement

Regular functional testing: Use certified testing equipment (such as input circuit simulators and output load groups) every quarter to test safety circuits to verify response time and fault detection capabilities.

Firmware management: Update firmware annually through Safety Tool to integrate the latest safety algorithms and patches, ensuring compliance with evolving standards.

Spare parts inventory: Reserve at least one SPASI23 module for critical systems, as well as spare wiring terminals and fuses, to reduce downtime during replacement.

Other product models of ABB brand:

ABB UFC933A101 3BHE048062R0101

ABB A0650 3BHT300051R1

ABB SPS01 2VAA008278R001

ABB SPS03-5V 2VAA008280R001

ABB SPS03-15V 2VAA008281R001

ABB BP01-L 2VAA008282R101

ABB BP01-R 2VAA008282R301

ABB BP-K01-AA 2VAA008284R101

ABB MVR 0.80-10KA 800V AC/1000V DC

ABB GFD233A103 3BH022294R0103

ABB PM856AK01 3BSE066490R1

ABB SW-190148

ABB 560PSU02 1KGT011900R0001

ABB AFC094AE02

ABB UAD149A0011 3BHE014135R0011

ABB 3BHE014135R0011

ABB PFVL 141C DIM.D=810 3BSX670292-112

ABB 5SHY3545L0014 3BHE023784R0001

ABB 1TGE120021R001

ABB PM904F

ABB PCD231

ABB HIEE300661R0001 UPC090AE01

ABB FMT200-ECO2

ABB 3BHB040253R0001

ABB SC520M 3BSE016237R1

ABB REC670 1MRK004814-AG

ABB TGM5 P14436-1072510

ABB GOP2000

ABB GOP2010

ABB 3BHE030579R0003

ABB 1SVR040000R1700

ABB XUD194 XUD194A 3BHC018137R0001

ABB XV5628A

ABB Y129740-002

ABB YPI105C

ABB YPK112A 3ASD573001A13

ABB YPO104

ABB YPP-105F(YT204001)

ABB YPP110

ABB YPQ110A

ABB YPQ110A 3ASD573001A5

ABB С-093H

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626