Description

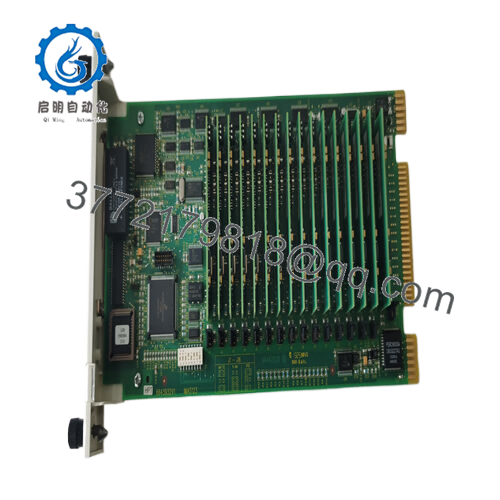

In the intricate fabric of industrial automation, where temperature fluctuations or subtle resistance shifts can derail precision processes—picture a steam boiler in a paper mill where errant thermocouple readings trigger unsafe shutdowns, or a pharmaceutical reactor where RTD drift skews batch quality, leading to discards and regulatory scrutiny—reliable analog signal acquisition is the unsung hero. These scenarios plague process control environments, where noisy field inputs from sensors overwhelm standard modules, causing data inaccuracies, false alarms, or integration snags that inflate downtime and engineering costs. The ABB SPASI23 rises to this as a 16-channel analog input module from ABB’s Symphony Plus series, the modern evolution of the Bailey Infi 90 IMASI23, delivering high-level signal conditioning for thermocouples (TC), millivolts (mV), and resistance temperature detectors (RTD) to ensure unwavering I/O signal fidelity in demanding setups.

This module asserts its value in distributed control systems (DCS) handling multi-sensor arrays, such as retrofitting legacy Infi 90 architectures for extended life without full overhauls, or in utilities where diverse thermal probes monitor turbine inlets amid vibration and EMI. In a food processing line, for instance, it captures RTD feedback from ovens under humid cycles, filtering noise to maintain ±0.1% accuracy and prevent overcooking variances. For petrochemical distillation towers, the ABB SPASI23 processes TC chains across zones, enabling scalable diagnostics that flag open circuits before they cascade into yield losses. It’s a must-have for modular expansions, where high-reliability inputs bridge field devices to central controllers without signal degradation, aligning with goals of system stability in harsh enclosures.

Engineered for the engineer’s toolkit, it supports universal sensor types—J/K/E thermocouples to Pt100 RTDs—with burnout detection to isolate faults swiftly. In EMI-saturated plants or remote outposts, its galvanic isolation fortifies paths, while hot-swappable design minimizes intrusion during live ops. For teams upgrading to Symphony Plus, the ABB SPASI23 demystifies migration, reusing Infi 90 footprints to cut reconfiguration time, turning potential bottlenecks into robust, future-ready nodes in industrial automation where precision sensing underpins every loop.

SPASI23

SPASI23

Slotting the ABB SPASI23 into your DCS framework reveals it as the steadfast aggregator for thermal and low-level signals, where it conditions 16 isolated channels to feed clean digital representations into Symphony Plus controllers or compatible backplanes. This module integrates via the INFI 90 bus or Symphony’s S+ network, positioning it at the field I/O layer—directly above transducers but below logic engines—while supporting redundancy through dual modules for failover in critical paths. In a typical stack, it pairs with output siblings like SPAO23 for closed-loop control, distributing load across cabinets without bus overloads.

Operationally, each channel auto-detects sensor types, applying linearization for TC cold-junction compensation or RTD 3/4-wire schemes to yield mA-equivalent outputs with 16-bit resolution, syncing via Modbus or Profibus extensions for HMI polling. Diagnostics embed via status LEDs and software interfaces, surfacing channel health—like lead breaks or overrange—directly in engineering tools for remote trending, ideal for process control where on-site checks disrupt flows. Without native redundancy, it thrives in duplex configs, where heartbeat polling ensures seamless handover, while expandable racks accommodate denser arrays in large-scale plants.

This seamlessness extends to hybrid environments: snap it into DIN rails with minimal cabling, configure ranges via front DIP switches or PC loaders, and test linearity with built-in simulators to verify against noise floors. For backplane veterans, the ABB SPASI23 feels intuitive, evolving sensor farms into resilient subsystems that scale with sensor proliferation, enhancing industrial automation from raw data chaos to refined, actionable insights.

| Specification | Details |

|---|---|

| Model Number | SPASI23 |

| Brand | ABB |

| Type | Analog Input Module (Symphony Plus) |

| Input Voltage | 24 VDC |

| Operating Temp Range | -20°C to 60°C |

| Mounting Style | DIN Rail / Rack |

| Dimensions | 269 x 361 x 74 mm |

| Weight | 2.1 kg |

| Interface/Bus | INFI 90 Bus / S+ Network |

| Compliance | CE, RoHS, UL |

| Supported Protocols | Modbus RTU, Profibus DP |

| Typical Power Draw | 8 W |

Opting for the ABB SPASI23 equips your sensing backbone with enduring accuracy that defies environmental gauntlets, its per-channel isolation—up to 500 Vrms—clamping noise to microvolt levels, ensuring thermal profiles hold true across gradients that would skew lesser modules and erode process yields. This fidelity cascades into operational poise, as auto-ranging adapts to TC/RTD variances without manual swaps, stabilizing loops in variable-temp zones like kilns or reactors where drift means scrap.

The deployment dividend compounds through Symphony heritage, where it inherits Infi 90 pinouts to repurpose legacy harnesses, compressing integration from weeks to shifts and easing opex in phased modernizations. Maintenance streamlines via onboard fault LEDs and diagnostic registers that log excursions preemptively, condensing hunts from panel teardowns to console queries—empowering teams to forecast sensor life rather than chase ghosts. Built for grit in steamy or dusty bays, it sustains linearity over thermal cycles, postponing verifications and harmonizing with audit paces in compliant ops.

Horizon-wide, it curtails ecosystem drag with efficient 8 W draw that slims cabinet cooling, while 16-channel density defers expansions for leaner footprints that flex with sensor growth. In high-reliability domains, the ABB SPASI23 tempers aggregate frailties, from burnout alerts that quarantine bad probes to supervision that baselines drifts for early swaps, crafting a sensing lattice that endures caprice in process control.

In pulp and paper mills, the ABB SPASI23 harvests TC inputs from digester zones, conditioning signals amid steamy vapors to anchor critical system uptime in process control environments where temp fidelity guards pulp quality. Its high-reliability RTD handling filters EMI from agitators, ensuring seamless batch flows.

Cement kilns deploy it for multi-point pyro profiles under abrasive dust, overseeing mV from thermocouples in high-vibration shafts—delivering precise I/O signals for continuous clinkering where deviations spell kiln rings. In semiconductor fabs, it monitors chamber RTDS in clean, thermal-swing vaults, supporting modular arrays for etch uniformity. These arenas crown the ABB SPASI23 as a sensor savant in arduous, precision-bound industrial automation, where input purity propels unyielding performance.

IMASI23 – Legacy Infi 90 predecessor for brownfield compatibility in basic thermal setups.

SPASI11 – Voltage/current variant for broader analog ranges in hybrid sensor mixes.

SPAO23 – Companion output module for balanced actuator signaling.

SPASI13 – High-density 32-channel edition for expansive monitoring needs.

SPDSI23 – Digital input counterpart for mixed I/O expansions.

Symphony Plus Kit – Configuration toolset for Symphony migrations.

SPASI22 – Enhanced isolation model for EMI-critical zones.

Bailey AI Module – Universal add-on for non-thermal mV/RTD bridging.

Before racking the ABB SPASI23, align bus connectors with your Symphony chassis—slight offsets ghost channels, so bench-verify continuity if splicing gens. Scrutinize 24 VDC for <2% ripple, as hum infiltrates low-mV paths; ferrite clamps help if VFDs nearby buzz. Load firmware parity via ABB’s updater to dodge handshake stalls during Modbus inits.

Astride, nurture distills to lean scans that mesh with rotations. Monthly, parse LEDs for channel vigils—steady norms clear decks, but blinks beckon a register pull to trace outliers. Semiannually, loop test signals through spares to peg linearity under 0.2%, and swab terminals against oxide in humid holds. Profibus arms crave quarterly cable audits for attenuation, twinned with annual rack-wide sims to affirm bus loads. Per ABB’s field ledger, this tempo frames the ABB SPASI23 as a tacit curator, reaping acuity with sparing lifts in your sensing vigil.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626