Description

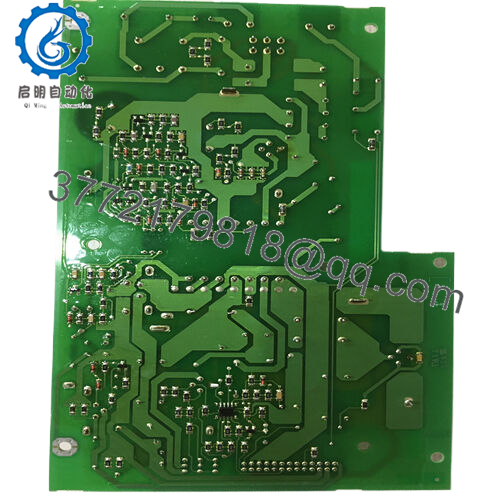

Product Model: SDCS-POW-1

Product Brand: ABB

Product Series: DCS / Drive Spare Modules

Product Features:

- Coated version for enhanced resistance to moisture and dust

- Designed for ABB DCS500 (drive) modules as a dedicated power supply

- Lightweight (≈ 0.44 kg) with compact footprint for module integration

- Provides regulated auxiliary and DC voltages for downstream control electronics

- SDCS-POW-1

- SDCS-POW-1

Product Role & System Fit

In an ABB drive system, power management is critical. The ABB SDCS-POW-1 serves as the dedicated power supply module that delivers the essential auxiliary voltages necessary for controlling, sensing, and logic electronics within the system. While the drive’s main power section handles heavy current conversion, the POW-1 handles the “housekeeping” power—ensuring stable low-voltage rails independent of main line fluctuations.

In practice, the ABB SDCS-POW-1 (also called a coated power supply board) is inserted into the electronic tray of the DCS series or DCS500-compatible modules. It works in tandem with control boards (e.g. signal processing boards, analog/digital I/O, communication modules), offering compatibility with the larger ABB automation architecture. Because it’s a coated version, the SDCS-POW-1 ensures better protection in harsher environments—ideal in medium-voltage drives installed in plants with dust, humidity, or corrosive atmospheres.

From the system integrator perspective, this module must be compatible in terms of mechanical footprint, connector pinouts, and electrical interface. Replacement or upgrade requires matching version (coated vs. uncoated), proper matching to downstream boards, and verifying voltage tolerances.

Applications & Industry Context

In heavy industry settings—steel mills, paper plants, chemical processing, cement factories—industrial drives regulate motor speed, torque, and energy use. In many of these installations, the ambient environment can be punishing: humid atmospheres, airborne particulates, occasional temperature spikes, even condensation.

A module like ABB SDCS-POW-1 finds use in retrofits, maintenance spares, and emergency replacements in those settings. For instance, a pulp & paper mill might keep SDCS-POW-1 units in stock to support its fleet of older ABB DCS500 drives. If a plant experiences a drive failure in the dead of night, having a replacement power supply board on hand can reduce unplanned downtime dramatically.

In mining or mineral processing, where dust and spikes in temperature are common, the coated nature of the SDCS-POW-1 is advantageous: it helps prevent corrosion on PCB traces or connectors and enhances longevity. In a petrochemical plant with tight redundancy requirements, having a reliable drive power module is nonnegotiable—failure of the power board may cascade down to losing control of the entire motor or drive stack.

It’s also used in marine or offshore platforms where humidity and salt-laden air compromise standard boards. The SDCS-POW-1 helps maintain integrity in those harsher climates.

From a practical viewpoint, engineers often remark that when they’ve replaced a faulty SDCS-POW-1 in the field, much of the downstream electronics resume operation immediately—without needing to reflash firmware or reconfigure logic. That makes it a truly plug-and-play spare for many installations.

Technical Features & Benefits

The ABB SDCS-POW-1 stands out due to its focused, robust design and field-proven role. Below are key technical features interwoven with how they benefit your deployment:

- Coated PCB Construction: This version of SDCS-POW-1 comes with conformal or protective coating, which guards against moisture, condensation, dust, and chemical vapors. That extra layer of protection is especially useful in industrial environments where uncoated PCBs might degrade prematurely.

- Regulated Auxiliary Voltages: The module is engineered to provide stable auxiliary rails (often XAUX or similar) that are vital for the control electronics (logic, sensors, analog/digital circuits). It maintains voltage regulation within tight tolerances even under supply fluctuations, ensuring downstream modules do not see voltage sag or noise.

- Compact & Lightweight: At around 0.44 kg net weight, the module doesn’t drastically contribute to cabinet load, yet remains robust enough for industrial use. Its small footprint simplifies board stacking and tray integration without consuming excess space.

- Auto Voltage Detection / Flexibility: The supply may handle a range of AC input (e.g. 115 V or 230 V AC) via automatic detection or jumpers, depending on the version (typical for ABB’s modular boards). This versatility reduces the overhead of stocking multiple variants. (Analogous features are documented for related boards in the DCS800 family

- Low Inrush & Soft Start: To reduce stress on fuses and upstream supply, the SDCS-POW-1 is designed to limit inrush current via internal soft-start or NTC-based measures, mitigating voltage dips when power is applied.

- High Reliability & Field Proven: As an ABB original module, SDCS-POW-1 has a long track record in industrial drive environments. Its known compatibility with existing DCS500 systems means lower risk of integration issues.

- Thermal Stability & Overload Protection: The design accounts for temperature rise in enclosed control cabinets. Overload protection (e.g. fusing on input lines) ensures that faults or downstream shorts don’t cascade damage other boards.

In real-world deployments, installing a fresh ABB SDCS-POW-1 often solves issues where downstream boards experience undervoltage, erratic resets, or spurious faults—especially when the original power board has aged or been exposed to harsh contaminants.

Technical Specifications Table

| Specification | Value / Detail |

|---|---|

| Product Model | SDCS-POW-1 |

| ABB Type / P/N | 10012279 (coated version) |

| Net Weight | ≈ 0.44 kg |

| Intended System | ABB DCS500 / Drives / Spare modules |

| Input Voltage (AC) | 115 V or 230 V (auto-detect or version dependent) |

| Frequency Range | 45–65 Hz (typical) |

| Auxiliary Power Output | Regulated DC outputs for control electronics |

| Protection | Fusing, inrush limiting, overload protection |

| Environmental Protection | Coated / conformal protective treatment |

| Operating Temperature Range | (per general drive environment spec) |

| Mounting / Interface | PCB board form, connector interface consistent with DCS trays |

| Approvals & Standards | Original ABB OEM, RoHS compliance (coated version) |

Related Models

- SDCS-POW-4 – a higher-current or alternate version of the power supply board for DCS drives

- SDCS-POW-1-COAT – explicitly coated version (same as SDCS-POW-1 in many catalogs)

- SDCS-REB-1 – a regeneration or braking module in the DCS family

- SDCS-POW-H01 – used in DCS880 series drives (different family)

- PM851K01 – processor/control module often paired in drive systems

- CI853K01 – communication or interface board in ABB drive arrays

- DCS800 Power Supply Modules – alternate family with similar role in the DCS800 product line

Installation & Maintenance Insights

While the ABB SDCS-POW-1 is straightforward in concept, practical installation and maintenance benefit from a few hard-earned field tips:

- Inspect Before Insertion

Always visually inspect connector pins, solder joints, and the board’s coating (for any flaking or damage) before placing into the drive tray. Even tiny corrosion can cause “no connection” faults. - Sequence Power Application

When powering the system, apply the AC to the power supply section first, and verify that the module initializes (e.g. standby LED or signaling) before turning on the main drive bus. This ensures downstream boards see clean rails during startup. - Torque & Mating

Be careful on connector engagement—don’t overforce. Use consistent torque on screws or guide pins to prevent misalignment. A slight misalignment can damage delicate traces. - Use Fresh Fuses & Protection

Replace input fuses or protective devices when swapping in a new SDCS-POW-1. Old fuses may be fatigued and unreliable under surge conditions. - Periodic Visual Inspection

Under maintenance windows, visually inspect the coated board for signs of blistering or contamination. Even coated boards can suffer under extreme humidity over time. - Keep Spares & Log Part History

Keep a spare ABB SDCS-POW-1 module in your spare parts inventory. Log when each module was installed, and track any failures or anomalies—this helps in trend analysis and preemptive replacement. - Thermal Management

Ensure the control cabinet still has adequate ventilation or forced cooling. Even though this board is modestly powered, in tightly enclosed spaces heat buildup can degrade components over time.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626