Description

In the high-stakes domain of industrial automation, where accurate feedback from field sensors can prevent everything from equipment overloads to production bottlenecks, engineers regularly wrestle with the pitfalls of noisy signals, limited channel density, and the hassle of retrofitting measurement hardware into established drive systems. These pain points are amplified in dynamic environments like metal forming presses or winding machines, where imprecise data on current, voltage, or temperature leads to erratic motor behavior, heightened wear, or compliance risks that cascade into unplanned halts. The ABB SDCS-PIN-51A (3BSE004940R1) confronts these head-on as a precision measurement card tailored for ABB’s DCS800 and DCS500 drive families, delivering clean, multi-channel data acquisition to underpin robust process control and signal reliability. Picture a steel rolling mill: fluctuating line currents could mask faults in thyristor converters, inviting inefficiencies or trips, but the ABB SDCS-PIN-51A captures granular metrics—up to 16-bit resolution across analog inputs—filtering out interference to feed controllers with actionable insights that stabilize operations. It’s essential in setups demanding modular I/O expansion, such as upgrading legacy exciters or integrating into SCADA overlays, where high reliability translates to fewer false alarms and smoother scalability. This card dovetails with broader industrial automation strategies, easing the integration of diagnostics without sprawling wiring runs or custom amplifiers. By honing in on measurement fidelity, the ABB SDCS-PIN-51A shifts focus from reactive tuning to forward-looking optimizations, like predictive load balancing, making it a cornerstone for teams tackling the real-world frictions of drive-centric environments where data quality drives uptime.

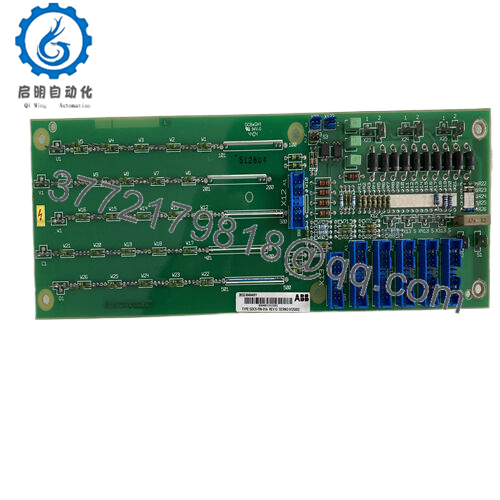

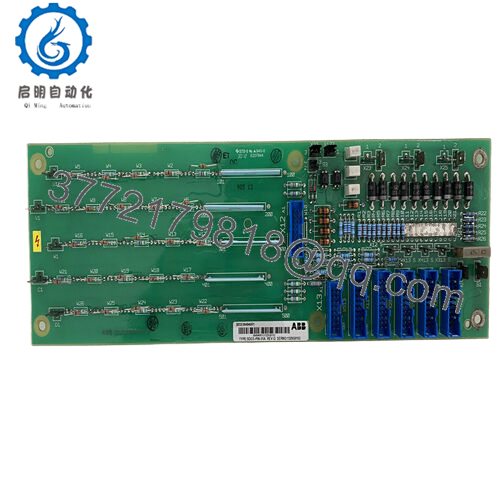

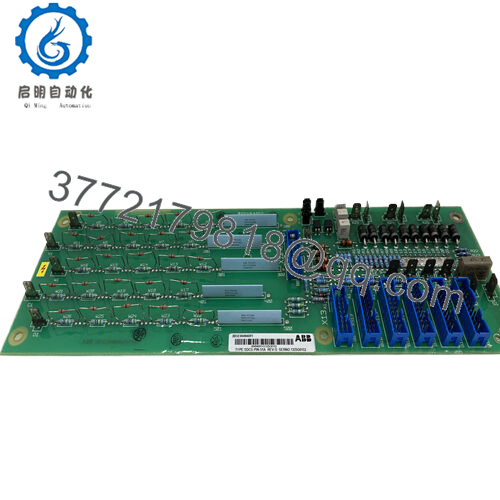

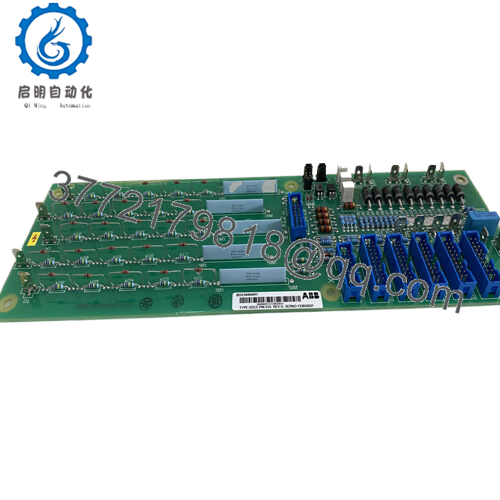

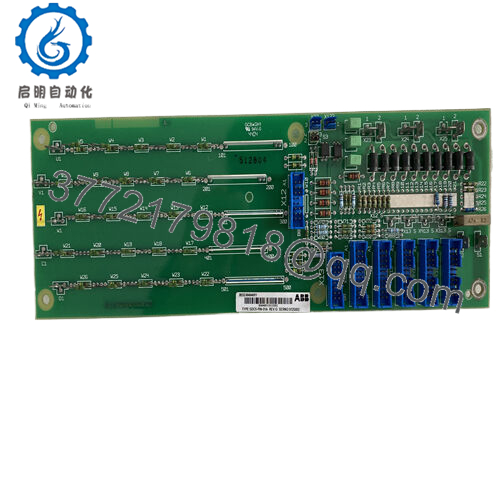

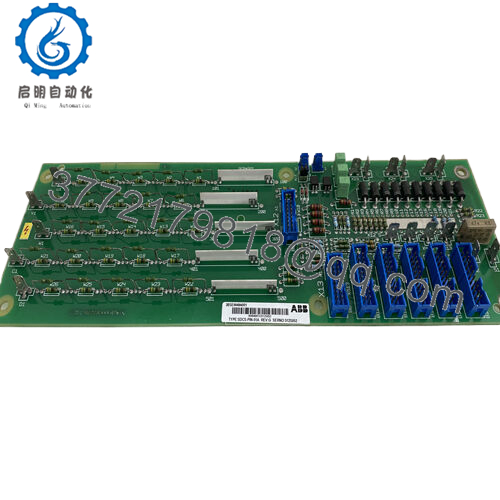

The ABB SDCS-PIN-51A slots into the feedback and monitoring tier of ABB’s DCS drive architectures, acting as a dedicated acquisition board that samples analog parameters from power stages, sensors, or transducers, then digitizes and conditions them for relay to the main control board like the SDCS-CON-2. It mounts directly onto the drive’s internal backplane via edge connectors, positioning it close to the heat sources in converter cabinets where it interfaces with the system’s fiber-optic or serial bus to stream processed data—think voltage/current scaling, temperature profiling, or fault threshold detection—with sub-millisecond latency to avoid loop delays. In a typical configuration, it handles diverse inputs like 4-20 mA loops from CTs or PTs, applying galvanic isolation to shield against EMI from switching thyristors, while supporting redundancy by mirroring channels in duplexed drives for seamless failover in continuous processes. Diagnostics shine through integrated status registers, accessible via Modbus or Profibus extensions, allowing HMIs to poll for overrange events or calibration drifts without halting the drive. This integration fortifies the I/O layer, bridging raw field telemetry to supervisory logic in backplane ecosystems, where it enables features like vector control tuning or exciter synchronization. For hybrid installs, the ABB SDCS-PIN-51A accommodates firmware updates through the drive’s loader port, ensuring compatibility across DCS variants without retooling the enclosure. Essentially, it serves as the discerning ear of your automation stack, distilling noisy realities into precise narratives that empower controllers to act decisively, fostering resilient architectures from compact skid-mounted units to expansive mill-wide networks.

- SDCS-PIN-51A

| Specification | Details |

|---|---|

| Model Number | SDCS-PIN-51A (3BSE004940R1) |

| Brand | ABB |

| Type | Measurement Card |

| Input Voltage | 24 V DC |

| Operating Temp Range | -10°C to +70°C |

| Mounting Style | Backplane |

| Dimensions | 150 mm x 80 mm x 20 mm |

| Weight | 0.2 kg |

| Interface/Bus | DCS Drive Bus |

| Compliance | CE, RoHS, EMC |

| Supported Protocols | Modbus, Profibus |

| Typical Power Draw | 3 W |

Bringing the ABB SDCS-PIN-51A into your drive setup instills a measurement backbone built for unflagging accuracy, where its multi-range sampling quells the distortions that might otherwise inflate error bands in torque estimates, yielding steadier motor performance and slimmer margins for scrap in tolerance-tight runs. This precision ripples outward, letting processes hum with less variance in feedback loops, so you can lean into refinements like energy profiling across shifts without the drag of recalibrating amid drifts.

Its backplane-native design also pares down deployment friction, as drop-in compatibility with DCS frames trims validation loops and spares the rework of external DAQ rigs, channeling efforts toward core logic enhancements over hardware hunts. Maintenance gains a sharper edge too, with self-reporting on channel health that pinpoints excursions early—via simple bus queries—compressing fault hunts to minutes and stretching calibration cadences, which in turn lightens the load on tech rotations and bolsters overall asset longevity.

Ultimately, the ABB SDCS-PIN-51A nurtures a data-rich foundation in measurement-heavy industrial automation, where such clarity not only fortifies day-to-day reliability but also unlocks pathways for layered intelligence, like anomaly detection overlays, all without the sprawl of auxiliary sensors or the pitfalls of signal washout.

In metal processing plants, the ABB SDCS-PIN-51A embeds within DCS800 converters for real-time current and voltage tracking in rolling stands, where it upholds high reliability against arc flash and thermal flux, anchoring process control environments that demand instantaneous fault capture to avert strip breaks in high-speed tandem lines.

Pulp mills deploy the ABB SDCS-PIN-51A to monitor exciter temperatures and field currents in paper machine drives, ensuring critical system uptime amid moist, fibrous exposures, with precise analog reads feeding adaptive speed controls for seamless web tension in continuous drying sections.

Marine propulsion systems integrate the ABB SDCS-PIN-51A into thruster controls, supporting fast data cycles for load sharing under saline vibrations and variable pitches, where its measurement prowess maintains propulsion integrity and fuel efficiencies in demanding offshore process control scenarios.

SDCS-PIN-41 – Pulse transformer variant for high-current interface in braking setups.

SDCS-PIN-20 – Basic power interface board for lighter DCS500 applications.

SDCS-CON-2 – Control board companion for logic integration with measurements.

SDCS-IOB-20 – I/O base module for expanded field connections in drive stacks.

DCS800-S01 – Drive frame that houses SDCS-PIN-51A for exciter duties.

SDCS-PIN-51-COAT – Coated version for corrosive atmospheres.

3BSE004941R1 – Enhanced measurement add-on for higher-resolution inputs.

DCF 505 – Overvoltage protection unit pairing for safe power tie-ins.

As you prep the ABB SDCS-PIN-51A for insertion, align its edge pins meticulously with the DCS backplane slots to dodge bent traces, and verify the 24 V DC rail’s stability—transients over 5% can skew initial offsets—while mapping input scalings to your sensor roster via the drive config tool to preempt range clips. Gauge cabinet humidity below 85% RH to honor the 70°C ceiling, routing sense wires shielded from inverter noise, and baseline a self-test cycle post-mount to confirm channel zeros without live power-up risks.

Keeping it tuned calls for periodic audits: harvest diagnostic logs bi-annually through the bus interface to trace noise floors or gain drifts, and reseat connectors after jolt-heavy runs to sustain contact integrity. Full-span calibrations yearly, using traceable sources against DCS software, lock in traceability, while a gentle ESD-safe wipe of traces wards off conductive films in gritty sites. These practices frame the ABB SDCS-PIN-51A as a dependable gauge, unmasking subtleties before they skew decisions and upholding your drive’s narrative with measured restraint.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626