Description

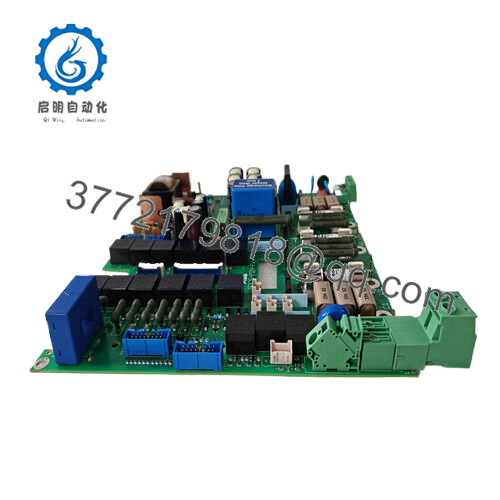

ABB SDCS-PIN-4B Product Description:

ABB SDCS-PIN-4B is a high reliability communication interface module designed specifically for connecting industrial automation systems with drives and motors. As part of ABB’s Software Defined Control Systems (SDCS) product portfolio, it seamlessly integrates with ABB’s ACS800 drivers, PLCs, and SCADA platforms, becoming a key component in the distributed control architecture. This module acts as a protocol converter, converting commands from protocols such as Profibus DP or Modbus RTU into driver specific signals, while aggregating real-time data to support predictive maintenance.

SDCS-PIN-4B

In the control system architecture, ABB SDCS-PIN-4B is located between the field equipment and the monitoring system. It connects the driver through a dedicated signal cable and controls the network through industrial Ethernet or serial interface, allowing engineers to remotely monitor the driver status, adjust parameters, and troubleshoot without physical access. For system integrators, their plug and play design does not require custom programming and can reduce debugging time by up to 30% compared to traditional solutions.

The irreplaceability of this module lies in its ability to handle mixed protocol environments. When modernizing old equipment in factories, ABB SDCS-PIN-4B can serve as a universal converter to ensure communication between traditional drives and state-of-the-art PLCs. This future oriented capability saves costs by extending the lifecycle of existing devices, while supporting gradual migration to smarter and more interconnected systems.

SDCS-PIN-4B

Main features and advantages:

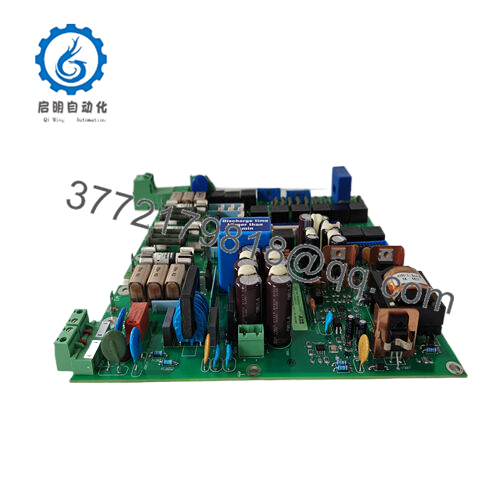

ABB SDCS-PIN-4B performs excellently in terms of functionality and performance, supporting data transfer rates of up to 12 Mbps, making it suitable for real-time control applications. Its dual port architecture supports network redundancy, ensuring continuous operation even in the event of a communication link failure – which is crucial for uninterrupted processes such as pharmaceutical production or data center cooling. The built-in error correction algorithm in the module can reduce signal noise and lower the risk of equipment damage or process interruption caused by communication errors.

In terms of hardware, the module adopts a compact DIN rail installation design (with a width of only 100 millimeters), which can be easily integrated into control panels with limited space. Its reinforced metal shell can withstand up to 5g of vibration and a temperature range of -25 ° C to+70 ° C. This robustness makes it suitable for harsh environments such as mines or paper mills, where dust, moisture, and mechanical stress are persistent challenges. The push in terminal of the module simplifies wiring, reduces installation errors and maintenance time, and has more advantages compared to screw terminal design.

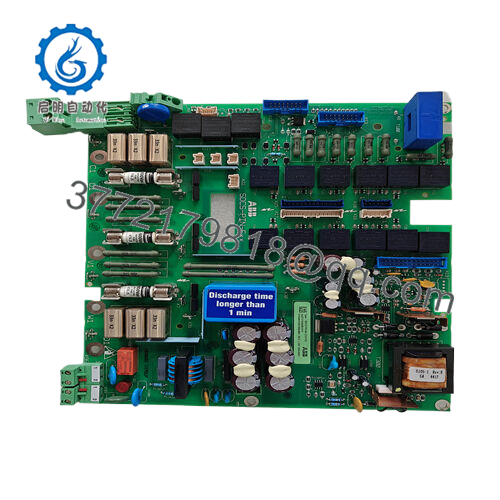

Compatibility is one of the core advantages of this module, which supports multiple industrial protocols from the factory, including Profibus DP, CANopen, and ABB’s own DriveBus. This flexibility enables it to integrate with third-party devices such as non ABB variable frequency drives or IoT gateways, making it a universal choice in multi vendor settings. In terms of network security, this module supports encrypted communication protocols to prevent unauthorized access in the interconnected factory.

Long term reliability is guaranteed through its self diagnostic function, which continuously monitors power stability, signal integrity, and thermal performance. The LED indicator lights provide clear status updates, while the firmware of the module can be remotely updated through ABB’s Drive Composer software to ensure compatibility with evolving automation standards. With an average time between failures (MTBF) of over 500000 hours, ABB SDCS-PIN-4B can provide decades of reliable service without requiring significant intervention.

SDCS-PIN-4B

Technical specifications;

Model ABB SDCS-PIN-4B

Brand ABB

Type: Industrial Communication Interface Module

Power supply 24V DC ± 10%

Working temperature -25 ° C to+70 ° C

Installation method: 35mm DIN rail (snap on design)

Size 100 x 110 x 60 millimeters (width x height x depth)

Weight 0.3 kilograms

Interface Profibus DP, CANopen, DriveBus, RS-485

Certification CE, UL, IEC 61131-2, ATEX (applicable to hazardous areas)

Data rates up to 12 Mbps (Profibus DP) and 1 Mbps (CANopen)

Redundant dual port network redundancy

Protection level IP20 (indoor), IK08 (impact resistance)

Contact Us

Phone:+86 16626708626

WhatsApp WeChat:+86 16626708626

Email: 3772179818@qq.com

SDCS-PIN-4B

Application areas:

In industrial environments, precise signal transmission and reliable connectivity are crucial, and the ABB SDCS-PIN-4B module provides critical support for seamless automation. Taking the automotive assembly line as an example, hundreds of drivers, sensors, and programmable logic controllers (PLCs) need to be synchronized in real-time. ABB SDCS-PIN-4Bacts as a neural network in this process, converting control commands from upper level systems into signals executable by variable frequency drives (VSDs), while transmitting operational data such as motor speed, torque, and fault codes back to the central control room. Without this module, signal misalignment may lead to misalignment of robot welding points, conveyor belt stagnation, or quality control system failure, resulting in high rework costs or downtime.

In the field of renewable energy, such as wind farms, ABB SDCS-PIN-4Bensures reliable communication between turbine inverters and grid management systems. It can handle high-frequency data exchange required for real-time adjustment of blade pitch and generator speed, optimize energy capture efficiency, and protect equipment from voltage surges. In the chemical industry, due to the presence of explosive environments, the requirements for fault safety connections are extremely high. The robust design of this module ensures uninterrupted signal transmission between the process controller and the hazardous area driver, avoiding safety accidents caused by communication delays.

Packaging machinery manufacturers also rely on ABB SDCS-PIN-4B to coordinate multi axis servo systems. For example, on a high-speed filling production line, this module transmits precise position commands and feedback signals at microsecond intervals, synchronizing the movements of the filling valve, capping machine, and labeling machine. This precision can reduce material waste and ensure that each bottle of product meets quality standards, which is crucial for industries where production efficiency is affected by small deviations.

SDCS-PIN-4B

Related products:

SDCS-PIN-4A – Early version, single port communication, suitable for basic driver control in non critical applications.

SDCS-PIN-4C – Enhanced model with built-in network security features, including firewall and encrypted VPN tunnel, suitable for industrial IoT environments.

SDCS-PIN-8B – Multi protocol version, supporting Ethernet/IP and Profinet, suitable for integrating drives into smart factory networks.

SDCS-CON-230- Matching controller module, used for complex motion control, can be used in conjunction with SDCS-PIN-4B to achieve multi axis synchronization.

SDCS-PWR-12B – Redundant power module, compatible with SDCS-PIN-4B, ensuring uninterrupted operation in fault prone systems.

SDCS-IO-16B – I/O Expansion Module, designed to expand analog/digital input/output for SDCS-PIN-4B, suitable for hybrid control systems.

SDCS-PIN-4B

Installation and maintenance:

Preparation before installation: Ensure that the control cabinet has sufficient ventilation (at least 25mm gap between modules) and is grounded to reduce electromagnetic interference (EMI). Connect Profibus using shielded twisted pair cables and separate power and signal wiring to avoid interference. For installation in hazardous areas, please verify whether the ATEX certification of the module matches the area classification and use approved cable sealing kits to achieve explosion-proof enclosures.

Maintenance: Conduct visual inspections every quarter to check for loose terminals or components affected by thermal stress. Use ABB’s Drive Composer software to monitor module health indicators such as signal delay and error rate, and schedule annual firmware updates to obtain new protocol support or security patches. In a dusty environment, clean the module vents with compressed air every six months to prevent overheating. For redundant systems, the fault transfer function is tested every six months by simulating network failures to ensure seamless switching between ports.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626