Description

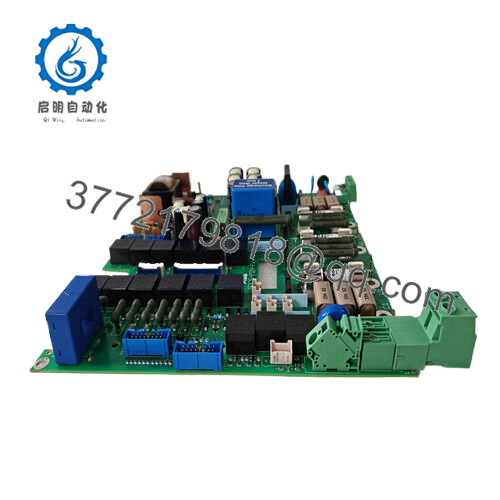

In the high-stakes realm of DC drive systems, where power fluctuations or interface glitches can grind operations to a halt—envision a steel rolling mill where erratic armature feedback triggers erratic speeds and material defects, or a crane in a port facility where voltage dips expose control loops to instability, risking overloads and safety breaches—reliable power interfacing is the bedrock of smooth performance. These pain points are rampant in industrial automation, particularly in legacy DCS setups where mismatched boards lead to signal noise, dropped commands, or inefficient energy routing that hikes opex and downtime in process control environments. The ABB SDCS-PIN-4B addresses this squarely as a power interface board for ABB’s DCS800 DC drives, engineered to bridge power electronics with control logic for precise armature and field handling, ensuring high reliability and seamless I/O signal flow under variable loads.

This board shines in retrofits of aging DCS400/800 architectures, where modular swaps extend asset life without panel teardowns, or in heavy-duty apps like metal extrusion presses demanding robust isolation to tame EMI from high-current paths. In a mining hoist, for instance, it conditions power signals amid dusty, vibration-laced shafts, stabilizing field weakening to prevent torque surges that could jam skips. For textile winders with regenerative braking, the ABB SDCS-PIN-4B filters transients for clean feedback, upholding system stability without nuisance faults. It’s essential for expansions in multi-drive cells, where its conformal coating variant wards humidity or particulates, aligning with goals of scalable integration in harsh zones.

Tailored for the engineer’s vantage, it supports dual-armature configs with opto-isolated gates, adapting to voltages up to 1500 V without derating. In EMI-dense floors or thermal-hot cabinets, its barriers shield against ground loops, while diagnostic ties flag overcurrents early. For teams modernizing brownfield sites, the ABB SDCS-PIN-4B simplifies upgrades, reusing DCS800 footprints to slash commissioning, transforming vulnerable interfaces into resilient hubs in industrial automation where drive precision dictates throughput.

- SDCS-PIN-4B

- SDCS-PIN-4B

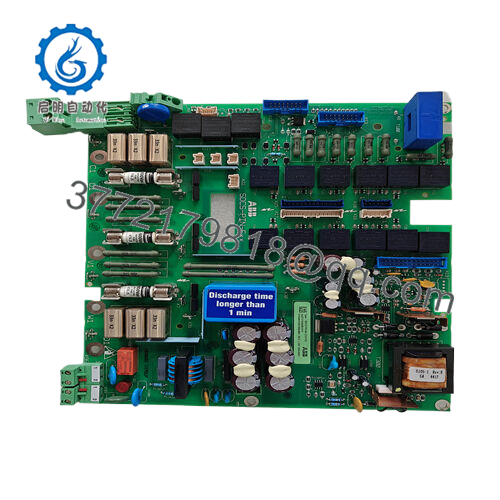

Integrating the ABB SDCS-PIN-4B into your drive stack casts it as the vital conduit between the power bridge and control processor, where it routes high-power signals—armature currents up to 4000 A, field supplies to 220 V—while conditioning gate pulses for SCR thyristors in ABB’s DCS800 enclosures. This board plugs into the drive’s backplane via edge connectors, nesting at the power I/O tier—directly interfacing converter stacks but feeding the PMC processor for closed-loop oversight. In a layered setup, it syncs with upstream PLCs via Profibus or analog refs, distributing loads across regenerative units without bus contention.

In flow, it amplifies gate drives with fiber-optic isolation to shun noise, enabling precise firing angles for speed ramps under 1% ripple, while auxiliary relays handle interlocks for braking choppers. Diagnostics route through status LEDs and serial links, surfacing bridge health—like snubber faults or phase losses—into DriveWindow tools for remote polling, crucial in process control where downtime probes disrupt shifts. Lacking inherent redundancy, it pairs with duplex drives for failover, where sync pulses ensure bumpless transfer, while optional coatings bolster it for marine or chemical exposures.

This adaptability reaches varied configs: mount it in IP00 cabinets with heat sinks, tune gains via DIP settings or software, and bench-test pulse fidelity to affirm against transients. For backplane pros, the ABB SDCS-PIN-4B demystifies power tiers, evolving raw converters into tuned systems that scale with torque demands, bolstering industrial automation from jittery drives to synchronized powerhouses.

| Specification | Details |

|---|---|

| Model Number | SDCS-PIN-4B |

| Brand | ABB |

| Type | Power Interface Board (DCS800 DC Drives) |

| Input Voltage | 24 VDC (Control), Up to 1500 VDC (Power) |

| Operating Temp Range | 0°C to 50°C |

| Mounting Style | Backplane / DIN Rail |

| Dimensions | 250 x 100 x 50 mm |

| Weight | 0.8 kg |

| Interface/Bus | Edge Connector, Fiber Optic Gates |

| Compliance | CE, UL, RoHS |

| Supported Protocols | Profibus DP, Analog |

| Typical Power Draw | 15 W |

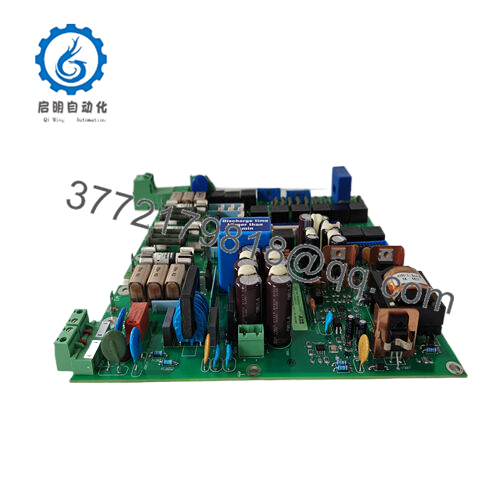

Deploying the ABB SDCS-PIN-4B infuses your drives with unyielding power fidelity that tames electrical chaos, its isolated gate amplifiers—delivering 20 mA pulses with <50 ns rise—ensuring SCR commutation holds firm across voltage sags, preserving torque linearity in apps where speed wobbles cascade into scrap or stalls. This resilience curbs energy losses by optimizing field currents to 1% regulation, easing thermal burdens on bridges and extending SCR life in regenerative cycles, all while its compact form fits legacy slots without airflow hits.

The assimilation boon unfolds in DCS800 affinity, where it inherits pinouts to reclaim existing harnesses, trimming retrofit spans from days to hours and lightening capex in fleet-wide swaps. Upkeep eases via embedded fault relays that log excursions for predictive pulls, shortening diagnostics from scope hunts to console scans—freeing techs for optimizations over overhauls. Forged for endurance in oily or humid bays, it clings to specs amid 50°C heats, deferring tweaks and syncing with MTTR goals in uptime-vital ops.

The long arc spotlights systemic savings—lean 15 W sip trims PSU sizing, while dual-channel handling defers add-boards for denser racks that adapt to amp creep. In high-reliability arenas, the ABB SDCS-PIN-4B dulls total exposures, from snubber monitors that preempt shorts to status chains that baseline drifts for timely spares, etching a drive scaffold that weathers surges in process control.

In metals fabrication, the ABB SDCS-PIN-4B pilots rolling mill drives, channeling armature power amid spark-laced arcs to lock critical system uptime in process control environments where speed fidelity averts strip tears. Its high-reliability gate isolation processes I/O signals from encoders, ensuring ripple-free ramps.

Elevator banks in high-rises enlist it for hoist traction, supervising field weakening under inertial loads in dusty shafts—yielding precise pulse trains for continuous lifts where deviations risk passenger jolts. In rubber extrusion, it guards calender rolls against regen spikes in steamy halls, facilitating modular torque shares. These fronts hail the ABB SDCS-PIN-4B as a power pivot in grueling, sync-thirsty industrial automation, where interface savvy sustains vigor.

SDCS-PIN-3 3ADT310400R0001 – Base variant for lower-current DCS400 drives with standard isolation.

SDCS-PIN-4-COAT 3ADT314100R1001 – Coated edition for corrosive or humid power sections.

SDCS-PIN-5X-1190 3ADT780007R0001 – Measurement-focused upgrade for advanced feedback loops.

SDCS-CON-4 3ADT220110R0001 – Control companion board for paired interface setups.

SDCS-PIN-2B 3ADT310200R0001 – Legacy model for compact, single-quadrant apps.

DCS800 S800 I/O Module – Expansion kit for denser analog/digital tie-ins.

SDCS-PIN-4A 3ADT316200R1510 – Predecessor with fiber gate enhancements.

PMC400 Board – Processor mate for full DCS800 control stacks.

Before backplane-seating the ABB SDCS-PIN-4B, match edge pins to your DCS800 slot—offsets fry traces, so continuity-check with a meter if mixing revisions. Vet 24 VDC control feeds for <5% ripple, as spikes corrupt gates; decouple with RC snubs if bridge noise bleeds over. Flash firmware via ABB’s tool to align with drive OS, lest mismatches stall boot sequences.

Astride duty, care pares to pragmatic sweeps that fit patrols. Bi-monthly, scan gate LEDs for pulse trains—crisp sequences affirm vigor, but drops cue a fiber reseat to nix bends. Quarterly, inject test currents to probe isolation resistance above 10 MΩ, and buff contacts against flux residue in arc-near spots. For coated units, annual visual scans for delams precede full-load sims to vet thermal risers under 40°C. Per ABB’s drive manual, this drill posits the ABB SDCS-PIN-4B as a sturdy linchpin, harvesting poise with lean inputs in your power flow.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626