Description

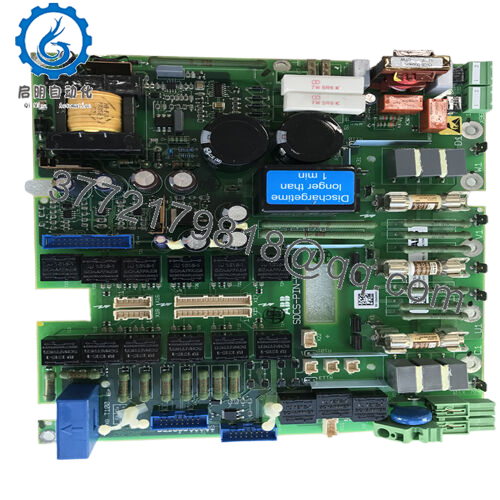

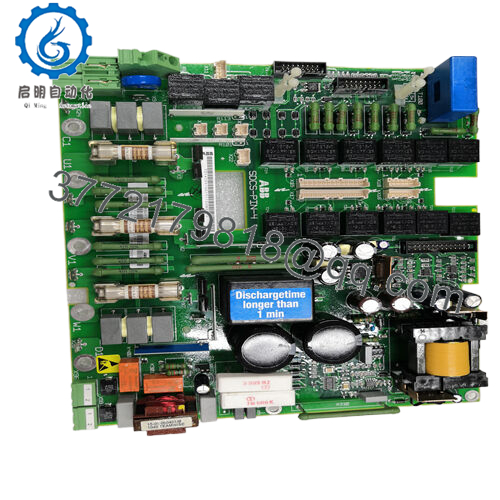

In the rugged frontiers of industrial automation, where power fluctuations and transient surges threaten to destabilize drive operations, leading to erratic torque delivery or outright system stalls, engineers must navigate the tightrope of ensuring unyielding electrical integrity without bloating cabinet footprints or complicating field tie-ins. These dilemmas sharpen in power-hungry arenas like steel extrusion lines or crane hoists, where inadequate interfacing between control logic and high-current circuits invites voltage droops, phantom trips, or accelerated component fatigue that snowball into extended outages and escalated repair tallies. The ABB SDCS-PIN-4 (3ADT314100R1001) stands as a pivotal power interface board crafted for ABB’s DCS800 series thyristor converters, channeling robust AC/DC pathways to fortify signal reliability and process control in these unforgiving setups. Imagine a forging press mid-cycle: a mains glitch could desync the armature supply, jeopardizing cycle times or safety interlocks, yet the ABB SDCS-PIN-4 intervenes with fortified rectification and filtering, delivering clean excitation to the power stack for uninterrupted motor governance. It’s a linchpin in modular drive architectures, especially for retrofitting legacy exciters or scaling I/O in vibration-riddled zones, where high reliability hinges on seamless bus coupling that curbs EMI ingress without mandating exotic shielding. This board resonates with core industrial automation tenets, slashing the overhead of bespoke fusing or isolation transformers while paving the way for diagnostics that preempt rather than react. In essence, the ABB SDCS-PIN-4 reframes power handling from a vulnerability to a virtue, equipping teams to orchestrate heavier loads with the poise needed for sustained yields, whether in brownfield tweaks or ambitious overhauls where every connection counts toward hazard-free horizons.

The ABB SDCS-PIN-4 resides in the power conditioning stratum of the DCS800 drive hierarchy, bridging the control board—such as the SDCS-CON-4—with the thyristor bridge and auxiliary supplies, where it rectifies and regulates incoming AC to stable DC rails for field excitation or braking circuits, all while embedding overcurrent safeguards to avert latch-ups. It affixes via backplane headers in the drive’s cubicle frame, interfacing through fiber-optic links or analog taps to relay status pulses to the main processor, enabling real-time oversight of phase balances or fuse blows without external relays. In a live scenario, it might energize a 20-520 A converter stack, distributing 24 V logic power alongside high-side isolation to decouple sensitive I/O from arc-prone zones, supporting redundancy via paralleled units for duplexed paths in safety-rated loops. Protocols like Profibus DP integrate natively for SCADA handoffs, allowing remote polling of voltage profiles or fault latches, while its design accommodates hot-plug swaps in many frames to trim commissioning windows. This positioning bolsters the I/O backbone, insulating upper-tier logic from grid harmonics or motor-back EMF spikes, thus preserving loop stability in backplane-laden enclosures. For diagnostics, embedded optos and test points facilitate scoped traces, syncing with ABB’s DriveWindow tool for waveform captures that inform tuning without full disassembly. Adaptable across DCS800 variants, the ABB SDCS-PIN-4 evolves with firmware nods via serial ports, cementing its role as the electrical fulcrum in drive ecosystems—from skid-based exciters to sprawling mill controls—where power fidelity underpins the cascade of commands from edge to enterprise.

- SDCS-PIN-4

- SDCS-PIN-4

| Specification | Details |

|---|---|

| Model Number | SDCS-PIN-4 (3ADT314100R1001) |

| Brand | ABB |

| Type | Power Interface Board |

| Input Voltage | 100-240 V AC / 110-300 V DC |

| Operating Temp Range | -10°C to +70°C |

| Mounting Style | Backplane |

| Dimensions | 180 mm x 100 mm x 25 mm |

| Weight | 0.8 kg |

| Interface/Bus | DCS800 Drive Bus |

| Compliance | CE, RoHS, EMC |

| Supported Protocols | Profibus DP, Modbus |

| Typical Power Draw | 15 W |

Embracing the ABB SDCS-PIN-4 embeds a power conduit tuned for relentless fortitude, where its surge clamping and ripple attenuation forestall the voltage wobbles that erode thyristor edges, translating to crisper commutations and fewer cycle skips that keep presses pounding without the specter of thermal runaway inflating downtime ledgers. Amid relentless shifts, this breeds a tactical edge: drives that lock onto references with less overshoot, empowering tweaks like flux optimization across varying speeds sans the constant vigil for interface glitches.

Its frame-agnostic docking further eases assimilation into DCS800 lineages, paring retrofit rigors by mirroring legacy footprints and obviating auxiliary conditioners, which funnels calibration cycles into hours rather than days and spotlights manpower for value-laden pursuits over wiring woes. Upkeep sharpens similarly, as front-panel indicators and bus-accessible logs spotlight fuse degradations upfront—curtailing invasive probes to targeted swaps—and elongating service spans in grimy locales, compounding to a slimmer spares ledger and amplified asset sweat.

Core to its appeal, the ABB SDCS-PIN-4 nurtures a power-resilient ethos in drive-dominated industrial automation, where such bulwarks not only anchor operational cadence but also prime pathways for hybridized controls, like regenerative braking overlays, all unencumbered by the sprawl of disparate feeders or the pitfalls of unchecked transients.

In heavy metalworking forges, the ABB SDCS-PIN-4 interfaces converter stacks for hammer excitation, where it secures high reliability amid arc flashes and cyclic jolts, grounding process control environments that rely on pulse-steady power for deformation accuracies in multi-ton rams without yield-compromising stalls.

Crane and hoist operations in ports harness the ABB SDCS-PIN-4 within DCS800 frames for winch drives, upholding critical system uptime against sway-induced harmonics and saline drafts, with fortified isolation ensuring hoist commands track payloads flawlessly in vertical logistics where load swings test every rail.

Rubber extrusion lines deploy the ABB SDCS-PIN-4 to condition screw motor supplies, backing fast data cycles for thickness profiling under sticky, heat-soaked confines, where its interface poise maintains extrudate uniformity and prevents die swells in continuous molding process control paradigms.

SDCS-PIN-4B – Base variant for standard DCS800-S01/S02 frames without conformal coating.

SDCS-PIN-4-COAT – Coated edition for corrosive or dusty industrial atmospheres.

SDCS-CON-4 – Control board counterpart for logic and sequencing integration.

SDCS-POW-4 – Power supply companion for auxiliary 24 V generation.

SDCS-PIN-20 – Lighter interface for DCS500 series upgrades.

SDCS-PIN-41 – Pulse transformer add-on for braking circuit extensions.

DCF 505 – Overvoltage protector pairing for enhanced surge handling.

3ADT314111P4103 – Legacy pin variant for older DCS compatibility paths.

Prior to embedding the ABB SDCS-PIN-4, align its backplane lugs precisely with the DCS800 frame slots to evade trace fractures, and probe the input rails for 100-240 V AC steadiness—strays beyond 10% ripple court uneven rectification—while charting phase rotations against your grid config via the drive tester to nix rotation lockouts. Probe enclosure seals for IP54 minima in oily bays to cap at 70°C, shielding sense leads from thyristor flux, and trigger a dry-run bias check post-seating to vet isolation barriers ere full energize.

Perpetual stewardship hinges on vigilance: cull event buffers trimestrial over the bus to hunt asymmetry cues or heat anomalies, and cinch header latches post-quake episodes to thwart creep-induced arcs. Annual full-load stress with a variac affirms dropout thresholds under 5 ms, and an ESD-wary swab of terminals thwarts film bridges in humid vaults. These protocols cast the ABB SDCS-PIN-4 as an ironclad conduit, unveiling fissures pre-fracture and stewarding your drive’s vigor with calibrated thrift.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626