Description

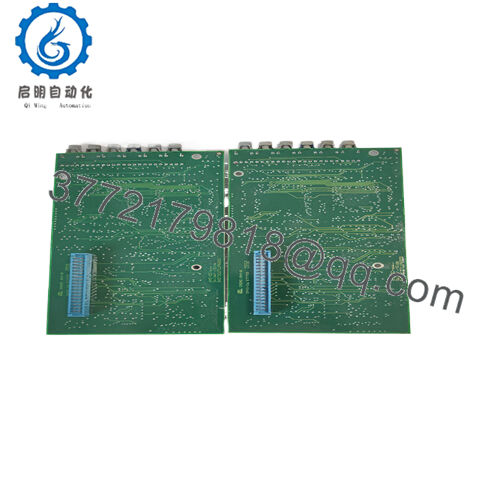

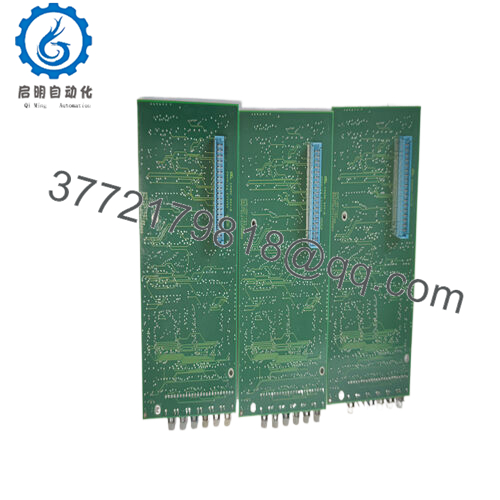

The ABB SDCS-AMC-DC2 is a precision control board specifically designed for ABB DCS600 and related direct current (DC) drive systems, playing a critical role in managing and optimizing DC drive operations. It functions as a vital control unit board that executes real-time system diagnostics, interfaces directly with I/O modules, and manages communication with power electronics within the drive system, ensuring smooth and efficient operation.

Used extensively in industrial automation industries like manufacturing, mining, and energy sectors, this control board is engineered to deliver precise drive control, essential for applications requiring reliable speed regulation, torque control, and system protection. It supports digital signal processing methods, maximizing control accuracy and dynamic response for DC motors in complex environments. Its integration capability with ABB DCS600 platform helps streamline data flow and system responsiveness, making it a go-to choice for engineers working on control systems needing robust digital control techniques.

- SDCS-AMC-DC2

Technically, the ABB SDCS-AMC-DC2 operates typically at a DC 24V supply voltage and is housed within a compact, durable engineering plastic frame measuring approximately 8.3 cm by 2.5 cm by 16.5 cm, and weighing around 0.1 kg. It features communication interfaces such as RS-232 for seamless interaction with drive electronics and system diagnostics tools. Built for reliability, it withstands industrial conditions while facilitating efficient system monitoring and fault management, reducing downtime and improving plant availability.

In summary, the ABB SDCS-AMC-DC2 is a specialized, rugged controller module integral to ABB’s DC drive solutions, engineered for precise, reliable, and integrated industrial automation performance in applications demanding exact drive control and system diagnostics.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626