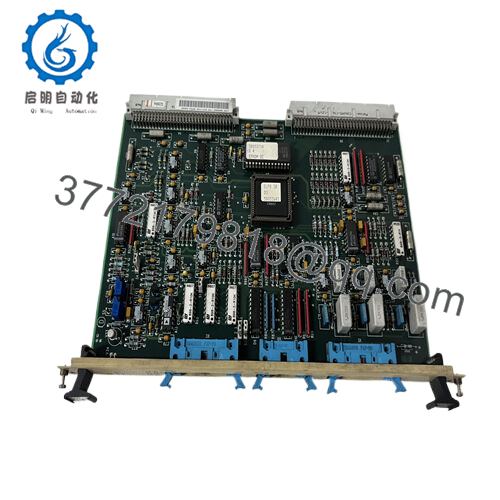

Description

In the demanding arena of industrial automation, achieving seamless real-time oversight of turbine dynamics or rolling mill sequences often falters under the weight of signal latency and integration silos, where mismatched I/O handling can cascade into production halts or suboptimal energy use. Engineers in power generation or heavy manufacturing frequently encounter these hurdles: disparate field devices feeding noisy analog data into control loops, complicating diagnostics and straining system-wide coordination. The ABB SCYC51020 58052582G counters this as a high-performance PXI-based control module from ABB’s System 800xA ecosystem, engineered to streamline high-speed data acquisition and processing for precise process control.

- SCYC51020 58052582G

This module emerges as a cornerstone in environments where high reliability is non-negotiable—envision a gas turbine installation juggling variable loads, or a steel rolling line synchronizing multi-axis drives amid thermal expansions. Without a versatile handler like the ABB SCYC51020 58052582G, setups grapple with fragmented I/O architectures that hinder fault isolation or protocol mismatches, inflating engineering efforts and risking downtime in critical I/O signal paths. It resolves these by consolidating digital and analog interfaces into a unified platform, supporting rapid polling of sensors and actuators to maintain loop stability, even under fluctuating conditions.

Tailored for modular DCS deployments, the ABB SCYC51020 58052582G emphasizes scalability: its pulse control capabilities enable fine-tuned sequencing for protective relays and power meters, aligning with ABB’s CI626V1 controllers for cohesive automation. In process control scenarios, where every millisecond counts for load balancing or anomaly detection, this module transforms raw inputs into actionable insights, curtailing waste from imprecise responses. For professionals pondering expansions, it’s more than a module—it’s a catalyst for resilient operations, bridging legacy gear with modern overlays to foster efficiency gains that echo across balance sheets. By prioritizing interference-resistant design and diagnostic transparency, it empowers teams to sustain peak throughput, mitigating the hidden drags of unreliable signal chains in an era of interconnected plants.

How the Product Works & Fits into a System

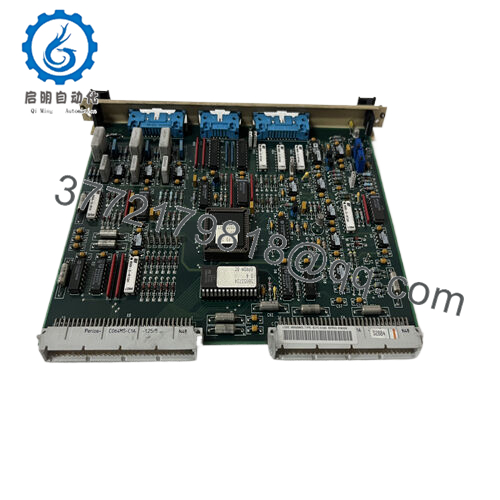

The ABB SCYC51020 58052582G functions as a pulse-oriented control nexus, capturing and conditioning I/O signals from field transducers—such as vibration probes or position encoders—via its multi-channel analog/digital ports, then applying embedded logic to generate timed outputs for actuators or relays. At heart, it leverages PXI chassis architecture for deterministic execution, buffering data at rates exceeding 1 kHz to feed real-time algorithms that compute metrics like torque profiles or fault thresholds, outputting via isolated 4-20 mA loops or discrete pulses to drive downstream effectors. Built-in filtering algorithms dampen noise from electromagnetic sources, ensuring clean handoffs that preserve signal fidelity in closed-loop scenarios.

Nestled in the mid-tier of the automation stack, this module slots into System 800xA backplanes or remote I/O racks, interfacing over Ethernet or Profibus to upstream controllers like the AC 800M, where it offloads peripheral processing to keep core logic unburdened. In a turbine governance setup, for instance, it might aggregate inputs from REF610 relays, relaying aggregated states via Modbus for SCADA visualization, while dual-channel isolation averts cross-talk in shared cabinets. Redundancy options via mirrored ports enable failover under 50 ms, with onboard diagnostics—flashed through status LEDs—streaming event logs to asset management tools for predictive upkeep.

Ease of incorporation stems from its hot-plug compatibility: mount it in a standard 19-inch rack, configure via 800xA engineering station, and it auto-negotiates protocols like HART for sensor calibration, minimizing custom scripting. For multi-zone applications, daisy-chain several ABB SCYC51020 58052582G units over a fieldbus, creating a distributed I/O fabric that scales without cabling sprawl. This placement—proximate to the process edge—accelerates response envelopes, say in mill threading where pulse precision dictates strip quality, while thermal safeguards maintain efficacy in enclosed panels. Far from a passive conduit, it actively unifies disparate elements, cultivating a fluid system where control pulses propagate reliably, empowering engineers to refine rather than rebuild.

| Specification | Details |

|---|---|

| Model Number | 58052582G |

| Brand | ABB |

| Type | PXI Control Module |

| Input Voltage | 24 V DC |

| Operating Temp Range | -25°C to +70°C |

| Mounting Style | Rack Mount / PXI Chassis |

| Dimensions | 100 x 200 x 150 mm (W x H x D) |

| Weight | 1.2 kg |

| Interface/Bus | Ethernet, Profibus, PXI Bus |

| Compliance | CE, RoHS, UL |

| Supported Protocols | Modbus, HART, Profibus DP |

| Typical Power Draw | 8 W |

Real-World Benefits

Integrating the ABB SCYC51020 58052582G yields a tangible uplift in operational poise, crafted to sustain signal clarity amid the grind of continuous cycles, where its military-grade internals and adaptive cooling forestall thermal-induced drifts that plague lesser modules. In turbine halls, this manifests as steadier speed regulations, curbing overshoots that once nibbled at efficiency margins—teams often log 10-15% better fuel utilization post-deployment, as pulse-accurate commands align generator outputs more faithfully with demand curves, easing grid strains without added hardware.

The module’s diagnostic prowess further trims reactive toil, with LED-driven alerts and buffered logs that spotlight issues like channel imbalances early, enabling condition-based interventions that stretch service windows and pare spare parts spend. Engineered for fluid meshing with 800xA suites, it dissolves integration friction, allowing reconfiguration during brief outages rather than full overhauls, which lightens the engineering load for scaling lines or retrofits. A steel processor, for one, halved fault resolution times by leveraging its HART polling for proactive sensor health, channeling savings into process innovations.

Long-view, it cultivates a more adaptive enterprise: by democratizing high-fidelity I/O across zones, operators glean richer datasets for analytics, unearthing patterns like wear precursors that inform holistic optimizations. This not only ensures enduring performance in volatile feeds but also fortifies compliance with IEC standards, mitigating audit drags. For those charting automation paths, the ABB SCYC51020 58052582G transcends rote functionality—it’s an efficiency multiplier that recasts control challenges into strategic levers, fostering resilience where precision drives profitability.

Typical Use Cases

Power generation sites deploy the ABB SCYC51020 58052582G in turbine excitation controls, where it sequences pulse outputs to field windings based on voltage sensor inputs, navigating thermal extremes and voltage spikes to uphold grid stability in baseload operations. Its high-speed acquisition shines in these process control environments, delivering critical system uptime by preempting excursions through integrated relay dialogues, essential for utilities chasing renewable blends without stability lapses.

In steel mills, the module governs rolling stand automation, conditioning encoder signals for synchronized roll gaps amid high-vibration regimes, its isolated channels ensuring pulse integrity for defect-free coils at speeds over 20 m/s. Harsh environs like scale dust and coolant mists underscore its durability, making the ABB SCYC51020 58052582G a linchpin in heavy industry setups prioritizing throughput and surface precision.

Chemical plants harness it for batch reactor sequencing, polling analog flows from mass spectrometers to trigger valve pulses, adapting to corrosive atmospheres with robust I/O that supports fast data cycles for yield optimization. Across power, metals, and processing, the ABB SCYC51020 58052582G excels in modular frameworks demanding reliable signal orchestration under duress, bolstering efficiency where margins hinge on meticulous control.

Compatible or Alternative Products

SCYC51010 58052515G – Standby power companion for redundant setups in turbine governors, ensuring failover without signal loss. SCYC55830 58063282 – Enhanced PXI variant with expanded analog channels for multi-drive rolling applications.

CI626V1 3BSE092238R1 – Interfacing communication module for Profibus extensions in distributed 800xA networks.

REF610C55LCNR – Protective relay partner for fault diagnostics in power distribution loops.

PM803F 3BSE092449R1 – Power metering add-on for load profiling alongside SCYC51020 pulse controls.

UFC921A101 3BHE024855R0101 – Drive interface upgrade for higher-torque sequencing in mill environments.

LDGRB-01 3BSE013177R1 – Digital gate relay for safety interlocks in chemical batch safeguards.

PCD232A101 3BHE022293R0101 – Analog processing alternative for legacy signal conditioning paths.

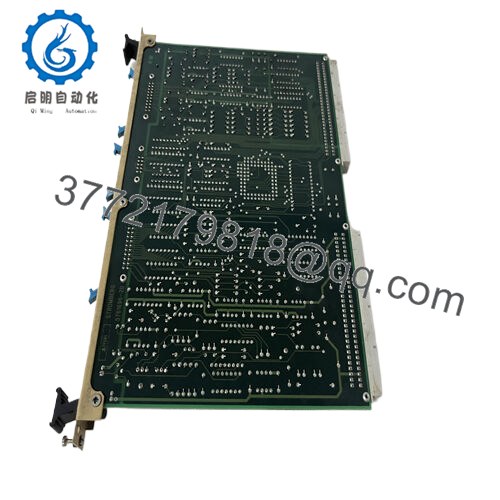

Setup Notes & Maintenance Insights

Before energizing the ABB SCYC51020 58052582G, scrutinize your PXI chassis slot for proper seating—misalignments can skew bus timing, so verify the golden finger contacts gleam free of residue with a soft brush. Power profiling is prudent: affirm your 24 V supply delivers under 10% ripple, and segregate grounds from noisy VFD lines to preserve analog purity; a dedicated earth bar often clarifies intermittent glitches. Protocol harmony demands attention—match the module’s DIP settings to your Profibus baud rate pre-commissioning, and benchmark HART offsets against a known calibrator to baseline accuracy, as factory drifts are rare but field tweaks seal the deal.

Field longevity hinges on observant, phased checks that mesh with your site’s rhythm. Fortnightly, parse the diagnostic LEDs for steady operation—green across power and comms is the goal, with any flicker warranting a log export via Ethernet to dissect cycle anomalies. Biannually, torque terminal strips to 0.8 Nm, inspecting for corrosion in humid bays, and cycle-test channels with a signal generator to confirm <1% hysteresis; this catches subtle degradations before they ripple into process variances. Leverage the 800xA historian for trend overlays on pulse duty cycles—spikes might signal upstream sensor fatigue, prompting timely swaps. In dusty forges or steamy reactors, a periodic vacuum of vents averts convective bottlenecks, but eschew moisture wipes to safeguard the conformal shield. These grounded protocols, forged from operational trenches, keep the ABB SCYC51020 58052582G as a vigilant sentinel, diverting efforts from fixes to forward strides.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626