Description

Real-World Use & Application Scenarios

In automated industries where monitoring and managing complex machinery and safety processes is paramount, specialized modules like the SCJIE00818 play a crucial role. This product is typically used in sectors such as manufacturing, energy, oil and gas, and critical infrastructure automation, where uninterrupted control and safety signal processing are mandatory. The SCJIE00818 is applicable in control systems designed to monitor, interface, or extend the capabilities of supervisory equipment, providing engineers with reliable performance in environments demanding precision and robustness.

This module supports industrial automation tasks such as signal conditioning, status reporting, and integration with safety instrumented systems. It is especially valuable where operators require real-time feedback on system status to maintain compliance with safety standards and avoid costly downtime. Built to withstand harsh industrial conditions, the SCJIE00818 offers integration flexibility ensuring it complements various control and safety architectures seamlessly.

Engineers often select the SCJIE00818 for applications involving redundancy monitoring, fault-tolerant signal distribution, or interfacing between different industrial communication protocols. Its proven utility in control panels and centralized monitoring rooms reflects its capacity to manage complex system data reliably while facilitating maintenance and diagnostic operations within industrial automation.

Product Introduction & Positioning

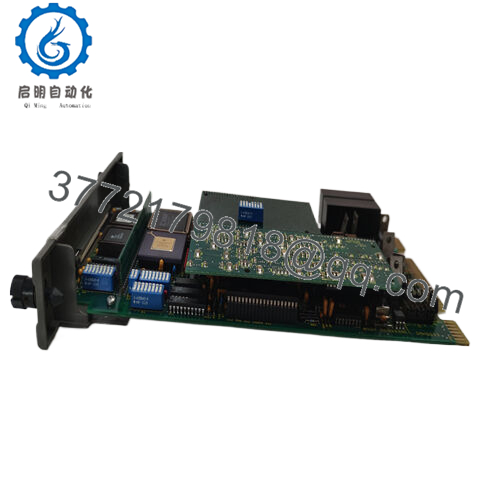

The SCJIE00818 is a precision signal interface module designed to deliver accurate status indication and communication within industrial control and safety systems. Positioned as a vital interface component, it facilitates connection between field devices and higher-level control or safety logic units, ensuring signals are transmitted and interpreted without loss or error. It is compatible with a broad range of industrial automation platforms and is optimized to support functional safety by ensuring data integrity and timely fault detection.

In the architecture of control systems, the SCJIE00818 functions as a translator and distributor of key operational signals. It helps centralize monitoring and control by providing clean, isolated outputs or inputs that reduce noise and interference. This module improves overall system reliability and integration simplicity, which is highly valued by system integrators managing complex infrastructure.

Engineers appreciate the SCJIE00818 for its robust design and ease of integration within existing systems. It reduces the need for additional signal conditioning hardware and streamlines both installation and troubleshooting processes in safety-critical environments.

Key Technical Features & Functional Benefits

The SCJIE00818 excels in providing stable and noise-immune signal interfacing to ensure that control systems receive accurate and reliable status information. Its hardware design incorporates galvanic isolation, which protects sensitive control electronics from electrical faults and transients common in industrial environments. This extends the life of connected devices and enhances system safety.

Equipped with LED indicators, the SCJIE00818 allows on-site personnel to visually verify signal status quickly, aiding preventive maintenance and fault diagnosis without needing complex tools. Its compact form factor supports DIN-rail mounting, optimizing space usage within control cabinets.

The module supports a variety of input and output signal types and is engineered to maintain high accuracy across a wide temperature range, ensuring dependable operation in demanding industrial settings. The robust enclosure protects internal circuitry against dust and mechanical impact, further enhancing long-term reliability.

By simplifying signal management, the SCJIE00818 reduces engineering complexity and helps maintain uptime. This module also facilitates compliance with safety standards by supporting well-defined signal integrity and error detection mechanisms.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | SCJIE00818 |

| Brand | ABB |

| Product Type | Signal Interface Module |

| Input Signal Types | Digital, Relay, Analog (specific types vary) |

| Output Signal Types | Digital, Relay Outputs |

| Operating Voltage Range | 24 V DC (typically) |

| Operating Temperature Range | -20°C to +60°C |

| Mounting | DIN Rail |

| Dimensions | Approx. 90 mm x 70 mm x 60 mm |

| Weight | Approx. 0.3 kg |

| Isolation Voltage | 2500 V AC (galvanic isolation) |

| Indicators | LED status indicators for inputs/outputs |

| Protection Rating | IP20 |

| Certifications | CE, RoHS, Industrial EMC standards |

- SCJIE00818

- SCJIE00818

Related Modules or Compatible Units

SCJIE00815 – Earlier generation signal interface module with limited input options but similar reliability.

SCJIE00820 – Advanced signal conditioning unit designed to extend capabilities of the SCJIE00818.

SCJIE00825 – Redundancy monitoring module that pairs well with signal interface units for high availability.

SCJIE00710 – Power supply module commonly used in control panels alongside the SCJIE00818.

SCJIE00910 – Communication gateway module enabling interface between SCJIE devices and control networks.

Installation Notes & Maintenance Best Practices

During installation of the SCJIE00818, ensure sufficient clearance for cooling and easy access to terminal blocks. Proper grounding and adherence to EMC guidelines are critical to prevent noise interference. The DIN rail mounting system provides mechanical stability but should be installed in a clean, dry environment free from vibrations.

Maintenance is generally low but includes regular visual inspection of LED indicators and tightening of electrical connections. Periodic testing of signal integrity is advised during scheduled shutdowns. Firmware or hardware updates, if any, should be applied according to manufacturer recommendations to maintain compatibility and operational security.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626