Description

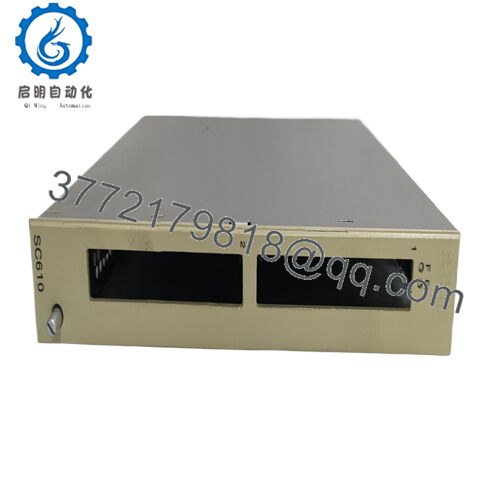

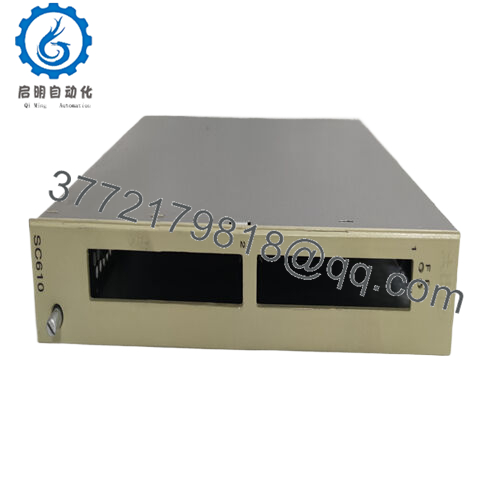

In the fast-paced world of industrial automation, where expanding communication capabilities without overhauling your control cabinet can make or break operational efficiency, engineers often encounter bottlenecks with limited space for adding fieldbus interfaces or data links. This becomes especially critical in legacy systems or compact setups, like those in oil refineries or batch processing plants, where the need for reliable process control demands more I/O channels and protocol support without compromising footprint or introducing wiring complexities. The ABB SC610 (3BSE001552R1) tackles these challenges as a dedicated sub-carrier module, enabling seamless expansion of communication functions within the ABB Advant OCS framework. Consider a scenario in a water treatment facility: as monitoring needs grow with added sensors for flow and quality metrics, squeezing in extra modules risks cluttering panels or weakening signal integrity, leading to delayed responses or integration headaches. Here, the ABB SC610 provides a stable platform to host up to two CI532 communication modules, boosting data transmission rates and protocol handling—like Profibus or Modbus—while maintaining high reliability in the I/O architecture. This approach supports your goals of modular integration and system scalability, reducing the engineering time spent on custom cabling or rack redesigns. In environments prioritizing process control and high-stakes uptime, the ABB SC610 ensures that expanding connectivity doesn’t equate to increased vulnerability, but rather to a more responsive automation network that adapts to evolving demands. It’s a practical enabler for teams aiming to future-proof setups amid tightening space constraints and rising data volumes in industrial automation.

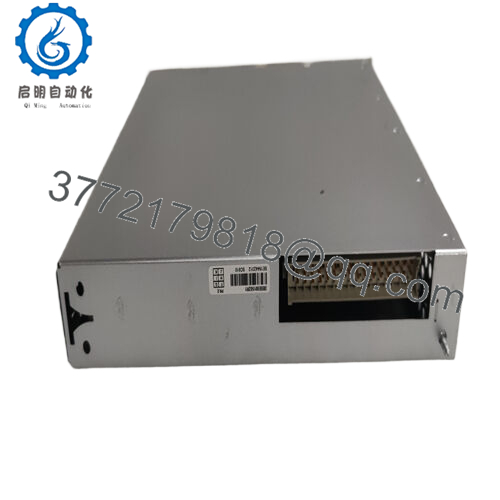

The ABB SC610 serves as a sub-carrier backbone in the Advant OCS distributed control system, specifically designed to mount and interconnect communication daughter modules like the CI532, positioning it as an extension layer in the overall I/O stack. It slots into the backplane or a standard rack alongside controllers such as the ACU or BCU units, where it acts as a physical and electrical bridge, distributing power and signals to attached modules without drawing excessive resources from the main bus. In a real deployment, you’d secure it via DIN rail or screw terminals in the cabinet, then snap in the CI532s for dual-channel fieldbus connectivity—handling tasks from remote diagnostics to real-time data polling from field devices. This setup supports redundancy through mirrored configurations, where a secondary ABB SC610 can take over if vibrations or faults disrupt the primary, ensuring continuous process control loops. Built-in diagnostics via LED indicators and status relays allow quick fault isolation, integrating with ABB’s System 800xA for centralized monitoring, while its compatibility with legacy protocols eases migration from older systems. Think of it as the unsung organizer in your automation hierarchy: it doesn’t process logic itself but empowers the communication tier, facilitating smoother interactions between edge sensors and core controllers in backplane environments. For scalability, multiple ABB SC610 units can chain together, expanding your network without rearchitecting the entire setup, making it a flexible fit for hybrid modernizations where reliability in signal paths is non-negotiable.

- SC610

- SC610

- SC610

| Specification | Details |

|---|---|

| Model Number | SC610 (3BSE001552R1) |

| Brand | ABB |

| Type | Sub-Carrier Module |

| Input Voltage | 24 V DC |

| Operating Temp Range | 0°C to +55°C |

| Mounting Style | DIN Rail or Rack |

| Dimensions | 160 mm x 25 mm x 130 mm |

| Weight | 0.2 kg |

| Interface/Bus | Advant OCS Backplane |

| Compliance | CE, RoHS |

| Supported Protocols | Profibus, Modbus (via CI532) |

| Typical Power Draw | 3 W |

Deploying the ABB SC610 brings a layer of architectural flexibility that’s engineered for longevity in constrained spaces, where its ability to host dual communication modules translates to fewer physical expansions and thus lower risks of cabling errors that could undermine I/O signal quality. Over time, this setup ensures consistent performance by stabilizing connections against industrial jostles, meaning your process control remains agile without the drag of frequent hardware tweaks—ideal for teams juggling upgrades on tight timelines.

What stands out in practice is how it trims integration overhead: by standardizing the carrier for CI532 attachments, engineers can prototype expansions off-site and deploy them with minimal reconfiguration, accelerating commissioning and cutting into the costs of skilled labor hours. Maintenance becomes more intuitive too, as the module’s compact design allows hot-swaps in many cases, preserving uptime during routine checks.

In essence, the ABB SC610 delivers on promises of enhanced modularity, fostering environments where automation evolves hand-in-hand with operational needs, all while upholding the high reliability that keeps critical systems humming through cycles of change.

Within power distribution networks, the ABB SC610 deploys as a sub-carrier for fieldbus extensions in substation controls, where space limitations in enclosures demand compact solutions for monitoring voltage regulators and ensuring critical system uptime amid electromagnetic noise and 24/7 loads. It enables dual Profibus links to remote RTUs, supporting fast data cycles for grid stability without panel overhauls.

Pharmaceutical manufacturing leverages the ABB SC610 in cleanroom process control environments, mounting CI532 modules to interface with sterile sensors for batch validation, where high reliability against contaminants and vibrations maintains compliance and seamless validation data flow in regulated operations.

Oil and gas platforms utilize the ABB SC610 for offshore I/O expansions, providing a rugged carrier in harsh, saline conditions to connect safety interlocks and flow meters, bolstering continuous uptime through redundant communication paths that handle rapid event logging.

CI532 – Primary communication module that mounts directly on SC610 for fieldbus expansion.

SC510 – Single-slot variant for lighter carrier needs in smaller cabinets.

BCU-01 – Base controller unit that integrates with SC610 for core Advant OCS processing.

ACU-01 – Application controller companion for logic handling alongside sub-carriers.

3BSE001460R1 – Enhanced sub-module for additional protocol support in legacy upgrades.

SD822 – Digital input module powered via the same backplane as SC610 setups.

AI521 – Analog input add-on for signal integration in expanded OCS architectures.

DO521 – Digital output unit, pairing with SC610 for actuator control extensions.

When preparing to integrate the ABB SC610, start by mapping your backplane slots to confirm compatibility with the Advant OCS rack—ensure at least two adjacent positions are free for the carrier and its CI532 attachments, and match the 24 V DC supply to avoid voltage mismatches that could strain the system. Factor in ambient conditions too; while it handles up to 55°C, position it away from heat sources or direct drafts in dusty sites, and verify enclosure IP rating exceeds NEMA 12 for vibration-prone areas. Run a pre-install firmware check using ABB’s configuration utility to align with your controller’s version, preventing handshake delays post-power-up.

Ongoing care keeps things predictable: monthly scans of connection points for tightness, especially after high-vibration shifts, paired with LED audits to flag any amber warnings early. Biannual full-system diagnostics via the OCS software can benchmark communication throughput, and if swapping CI532s, power down sequentially to isolate without broad disruptions. Dust off vents quarterly with compressed air to sustain thermal margins, ensuring the ABB SC610 supports your network reliably year after year.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626