Description

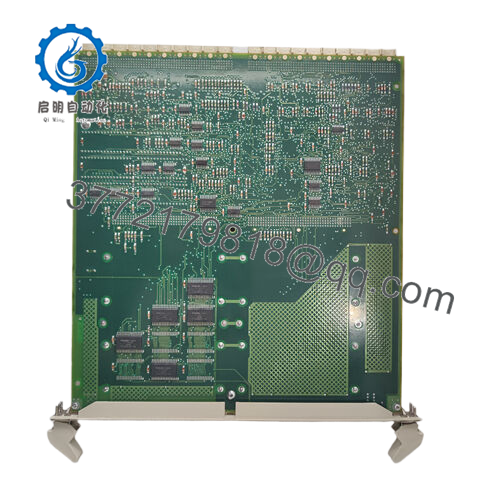

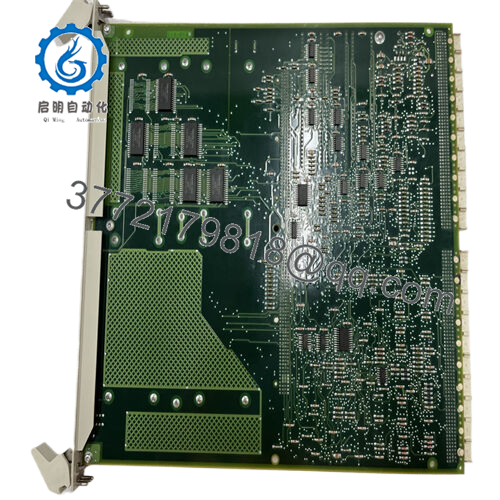

In the complex arena of legacy process control, where submodule carriers falter under communication bottlenecks or CPU overloads—think a batch reactor in a chemical plant where delayed fieldbus polling disrupts sequencing and yields off-spec runs, or a pulp digester in papermaking where I/O lags from outdated backplanes cascade into steam imbalances and fiber quality dips—seamless carrier integration is vital for sustaining modular architectures without constant overhauls. These hurdles plague industrial automation upgrades, especially in Advant OCS environments where mismatched carriers lead to signal dropouts, firmware incompatibilities, or scalability walls that escalate downtime and retrofit costs in high-reliability process control. The ABB SC520 3BSE003816R1 counters this as a submodule carrier with integrated local CPU from ABB’s Advant Master series, designed to host and interconnect submodules for robust data routing and local processing, ensuring high-fidelity I/O signal handling in extended DCS setups.

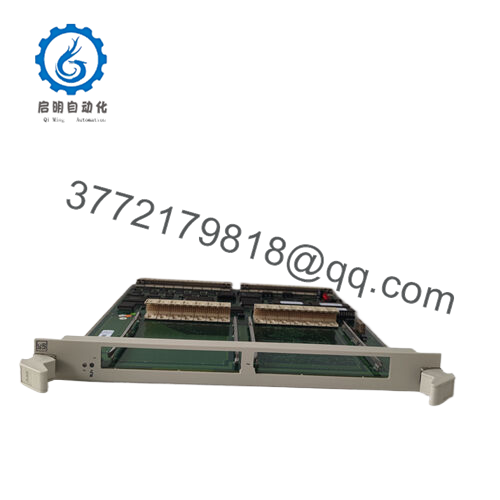

This carrier becomes indispensable in mid-tier applications like evolving MB300 or MB300E backplane systems, where modular expansion demands plug-compatible hosting without rack redesigns, or in marine-adjacent plants needing non-coated variants for standard enclosures. In a fertilizer granulator, for instance, it orchestrates submodule traffic amid dusty, humid cycles, buffering CPU tasks to prevent loop stalls that could clog feeds. For offshore platform tie-ins, the ABB SC520 3BSE003816R0101 supports local diagnostics to isolate comms faults, upholding system stability without halting gas compression. It’s a key enabler for brownfield migrations to Symphony Plus, where its RoHS-exempt design bridges legacy footprints, minimizing engineering disruptions in vibration-prone or EMI-challenged zones.

Focused on your deployment aims—scalability and fault isolation—it accommodates up to eight submodules with onboard CPU for edge computing, offloading master controllers for tighter response times. In thermal-variable processes or remote substations, its isolation guards against ground shifts, while status relays preempt cascading errors. For teams sustaining Advant OCS, the ABB SC520 3BSE003816R1 eases longevity, reusing bus standards to defer full-system swaps, repositioning carriers from maintenance magnets to reliable anchors in industrial automation where modular poise drives efficiency.

Positioning the ABB SC520 3BSE003816R1 within your process stack frames it as the modular scaffold for submodule ecosystems, where it mates MB300 backplanes to host I/O, communication, or processor cards, routing signals via the INFI-NET bus for cohesive DCS operation in Advant Master cabinets. This carrier integrates at the chassis level—directly above field modules but below central coordinators—leveraging its local CPU for preliminary tasks like data validation or failover buffering, while supporting redundancy through paired units in duplex racks. In a stratified setup, it links with upstream CI520 controllers or downstream AI modules, balancing loads across segments without network floods.

In routine, the embedded CPU handles polling at 1 ms cycles, conditioning analog/digital streams from hosted submodules for error-free handoff to Profibus or Modbus extensions, syncing with HMI for real-time views. Diagnostics flow via front LEDs and serial ports, highlighting CPU health or bus errors in engineering consoles—pivotal in process control where remote audits trump physical probes. Without native hot-swap, it deploys in powered-down slots for safety, yet its firmware hooks enable online parameter tweaks, while expandable bays scale to 16 carriers in large frames.

SC520 3BSE003816R1

SC520 3BSE003816R1

This flexibility spans legacy hybrids: latch it into DIN-compatible rails with minimal tooling, load configs via floppy or PC links, and cycle self-tests to confirm against crosstalk. For backplane stalwarts, the ABB SC520 3BSE003816R1 clarifies evolution, turning submodule clusters into extensible nodes that adapt to I/O growth, fortifying industrial automation from disjointed carriers to unified, resilient frameworks.

| Specification | Details |

|---|---|

| Model Number | SC520 3BSE003816R1 |

| Brand | ABB |

| Type | Submodule Carrier with Local CPU |

| Input Voltage | 24 VDC |

| Operating Temp Range | 0°C to 55°C |

| Mounting Style | Rack / Backplane |

| Dimensions | 300 x 291 x 130 mm |

| Weight | 2.5 kg |

| Interface/Bus | INFI-NET, Profibus |

| Compliance | CE, RoHS Exempt |

| Supported Protocols | Modbus, Profibus DP |

| Typical Power Draw | 10 W |

Choosing the ABB SC520 3BSE003816R1 fortifies your modular core with persistent interconnectivity that withstands protocol variances, its local CPU—clocked at 16 MHz—managing submodule handshakes to sustain 99.9% availability in looped networks, averting data stalls that fragment control in multi-vendor plants. This endurance trims process variances by queuing transients locally, stabilizing loops in apps where timing drifts mean batch rejects, while its rack footprint reuses Advant slots to preserve airflow without retrofits.

The onboarding value intensifies via INFI-NET lineage, where it salvages existing harnesses for swift submodule swaps, condensing migrations from quarters to fortnights and easing opex in decentralized ops. Stewardship simplifies through CPU-embedded logs that chronicle bus states for trend-based alerts, shortening fault traces from disassembly dives to dashboard pulls—enabling crews to preempt overloads rather than scramble post-event. Tempered for enclosures with moderate dust or heat, it clings to signal integrity over cycles, staving off alignments and meshing with uptime mandates in sustained realms.

The expanse illuminates thrift catalysts—efficient 10 W footprint lightens PSU demands, while eight-slot capacity postpones chassis adds for agile frames that yield to expansion. In high-reliability spheres, the ABB SC520 3BSE003816R1 mutes systemic frailties, from watchdog timers that quarantine hung submodules to relay chains that baseline loads for spares timing, forging a carrier web that navigates flux in process control.

In power utilities, the ABB SC520 3BSE003816R1 stewards MB300 backplanes for breaker I/O, channeling submodule data amid switchyard hum to secure critical system uptime in process control environments where comms fidelity averts grid flickers. Its high-reliability CPU buffers process I/O signals from vibration mounts, ensuring loop cohesion.

Pharma filling lines harness it for sequencer submodules under sterile swings, overseeing analog chains for nonstop vials—delivering local diagnostics that uphold signal purity and continuous uptime in regulated bays. In food extrusion, it anchors recipe carriers against thermal jolts in steamy halls, facilitating modular throughput shares. These domains exalt the ABB SC520 3BSE003816R1 as a modular maestro in taxing, integration-hungry industrial automation, where carrier cunning sustains cadence.

SC520M 3BSE016237R1 – Coated marine variant for humid or saline process enclosures.

CI520 3BSE001558R1 – Controller companion for enhanced master-submodule coordination.

MB300 3BSE002614R1 – Base backplane for standard rack integrations with SC520.

AI810 3BSE008516R1 – Analog input submodule add-on for field signal expansion.

DO810 3BSE008134R1 – Digital output mate for actuator drive pairings.

CI522 3BSE001559R1 – Upgraded interface for Profibus-heavy networks.

SC510 3BSE003815R1 – Simplified carrier without CPU for cost-bound setups.

MB300E 3BSE002615R1 – Extended backplane for denser submodule arrays.

Prior to chassis-locking the ABB SC520 3BSE003816R1, verify backplane mating—MB300 slots require flush pins to avert shorts, so ohm-out continuity if blending variants. Probe 24 VDC rails for <3% ripple, as surges tax the CPU; add regulators if nearby relays chatter. Update firmware through ABB’s legacy loader to sync with Advant OS, circumventing init freezes.

In tenure, oversight pares to tactical glances that align with audits. Monthly, survey LEDs for CPU and bus pulses—vibrant sequences endorse flow, but fades summon a serial dump to map anomalies. Biyearly, cycle submodule mocks to gauge handshake latency under 5 ms, and cleanse edge contacts from oxide in ambient holds. Profibus legs merit quarterly termination checks for reflections, mated with annual frame sims to vet load shares. Per ABB’s OCS ledger, this rhythm renders the ABB SC520 3BSE003816R1 a poised custodian, amassing fidelity with judicious tugs in your modular vigil.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626