Description

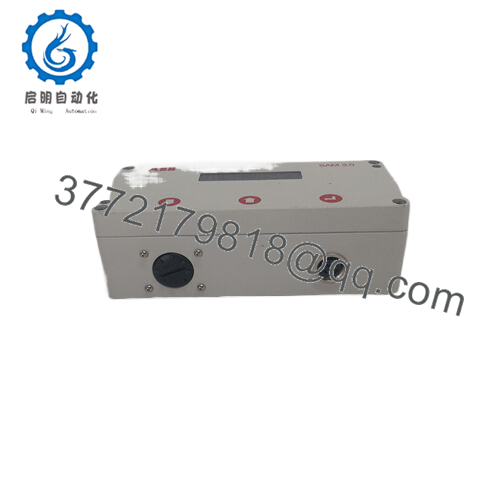

ABB SAM3.0 is a multifunctional industrial control and monitoring system. In terms of industrial control, it functions as an advanced modular automation system. This control module is designed to interface with various components in industrial environments.

SAM3.0

It has a wide input voltage range, typically 24-240 VAC, which makes it compatible with various power sources in different industrial applications. The output voltage range is 10-240 VAC, and the output current capacity is up to 5 A. This flexible power processing capability enables it to drive and control various industrial equipment.

SAM3.0

Main features and advantages:

In terms of communication, ABB SAM3.0 supports multiple industry standard protocols such as Modbus, Profibus, and Ethernet/IP. This extensive protocol support is crucial as it enables seamless integration with other devices in industrial networks. Whether communicating with sensors, actuators, or other control systems, ABBSAM3.0can efficiently exchange data for real-time monitoring and control. It has an IP65 protection rating, which means it has excellent protection against dust and water. This makes it suitable for harsh industrial environments where dust and moisture are common. Its working temperature range is -25 ° C to+70 ° C, further highlighting its durability and enabling it to operate normally under extreme temperature conditions. In addition, its storage temperature range is -40 ° C to+85 ° C, ensuring its durability even when not in use. It also holds certifications such as CE, UL, and CSA, which are globally recognized safety marks indicating compliance with international standards.

In terms of mechanical monitoring, ABB SAM3.0 is an advanced system that can monitor various machine parameters in real-time. It can monitor vibration, which is an important indicator of the health status of the machine. Abnormal vibration may indicate issues such as misalignment, bearing wear, or load imbalance. By continuously collecting and analyzing vibration data, the system is able to detect potential problems long before they cause machine malfunctions. Temperature monitoring is another important function. Overheating can cause serious damage to machine components, and ABB SAM3.0 can accurately track the temperature of critical components. It also monitors speed to ensure that the machine operates within the expected range. This real-time data collection and analysis enables operators to make informed decisions, perform proactive maintenance, and reduce unplanned downtime.

In high-voltage applications, ABB SAM3.0serves as an advanced monitoring system for medium and high voltage networks, as well as gas insulated switchgear (GIS). It can measure leakage current, which is crucial for evaluating the integrity of insulation in high-voltage systems. Leakage current may indicate insulation aging, and if left untreated, it may lead to electrical breakdown. The system can also count and classify surge amplitudes. It can sensitively record surges from sources such as lightning strikes and switch operations. Then, these surge amplitudes are combined with the total leakage current and displayed in digital form on an electronic screen. This provides operators with a comprehensive view of the electrical condition of the high-voltage network. The system categorizes surge current pulses into three types and records the time and date information (timestamp) of overvoltage events. These historical data can be used for in-depth analysis of network performance and prediction of potential issues.

ABB SAM3.0 is designed to be compact and aesthetically pleasing. This not only minimizes space requirements to the greatest extent possible, but also makes it relatively easy to install and integrate into existing infrastructure. The ergonomic connectors and easy to read indicator lights on the device further simplify the installation process. Its modular design also makes maintenance easier, as individual components can be replaced or upgraded without the need for major repairs to the entire system. It is made of high-quality materials, ensuring long-term durability even in the most demanding industrial environments. The precision engineering of ABB SAM3.0 ensures its consistent performance over a long period of time.

SAM3.0

Application areas:

In manufacturing plants, ABB SAM3.0 can be used to monitor and control various equipment. For example, in a factory that produces automotive parts, it can be installed on a conveyor belt to monitor its speed and vibration. This ensures smooth material flow and enables early detection of any mechanical issues that may interrupt production. In energy related industries such as power plants, ABB SAM3.0 can be used to monitor high-voltage switchgear. By measuring leakage current and classifying surge amplitudes, it helps maintain the safety and reliability of the distribution network. In the chemical industry, precise control of processes is crucial, and ABB SAM3.0 can be used to control the speed and temperature of mixing equipment to ensure consistent product quality.

SAM3.0

Installation and maintenance:

Before installing ABB SAM3.0, it is necessary to ensure that the power supply voltage at the installation site is within the input voltage range of the equipment. It is also necessary to verify the compatibility of communication protocols with existing industrial networks. Adequate installation space should be allocated, while considering the size of the equipment and appropriate ventilation requirements.

It is crucial to follow the detailed guidelines provided in the user manual during the installation process to ensure the proper functioning of the device.

For maintenance, it is recommended to regularly check the connectors for signs of wear or corrosion. The performance of equipment should be regularly evaluated by comparing monitoring parameters with expected values. Software updates should be installed promptly to take advantage of new and improved features.

SAM3.0

Other ABB product models:

ABB 3AUA0000036521

ABB 3AUA0000110430

ABB 3BDS005799R1 PM665

ABB 3BHB003688R0101

ABB 3BHB003688R0101

ABB 3BHB003689

ABB 3BHB003689

ABB 3BHB003689

ABB 3BHB003689 3BHB003688R0101

ABB 3BHB005243R0105

ABB 3BHB005243R0106 KUC755AE106

ABB 3BHB005243R0117

ABB 3BHB005245R0101

ABB 3BHB005922R0001

ABB 3BHB006309R0001

ABB 3BHB006338R0001

ABB 3BHB006714R0217 SYN 5201a-Z.V217

ABB 3BHB006715R0277

ABB 3BHB007030R0102 UFC760BE102

ABB 3BHB012961R0002

ABB 3BHB015651P0001

ABB 3BHB015651P0001

ABB 3BHB015651P0001

ABB 3BHB015651P0001

ABB 3BHB030310R0001

ABB 3BHB043807R0001

ABB 3BHB043808R0001

ABB 3BHE003604R0102

ABB 3BHE003604R0106

ABB 3BHE004573R0142

ABB 3BHE006373R0101

ABB 3BHE006412R0101

ABB 3BHE009681R0101

ABB 3BHE014377R0001 PVD164

ABB 3BHE017628R0002 PPD115A02 SG579989013

ABB 3BHE022293R0101

ABB 3BHE022293R0101

ABB 3BHE022294R0101 GFD233

ABB 3BHE023784R0001

ABB 3BHE024313R0101 KSD211A101

ABB 3BHE024577R0101

ABB 3BHE024577R0101 11790750105 PPC907BE

ABB 3BHE024747R0101

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626