Description

Real-World Use & Application Scenarios

The ABB SAFT183VMC is a safety monitoring and control module widely used in industrial automation sectors where functional safety is a top priority. This module is commonly deployed in process industries such as chemical plants, oil and gas facilities, food and beverage manufacturing, and power generation, where safeguarding personnel and equipment through reliable safety systems is critical. It is designed to support safety-related automation tasks, including emergency stops, safety gate monitoring, and interlocking, providing essential protection to prevent accidents and unplanned shutdowns. The SAFT183VMC addresses challenges in integrating safety functions into complex control systems while maintaining high availability and compliance with international safety standards.

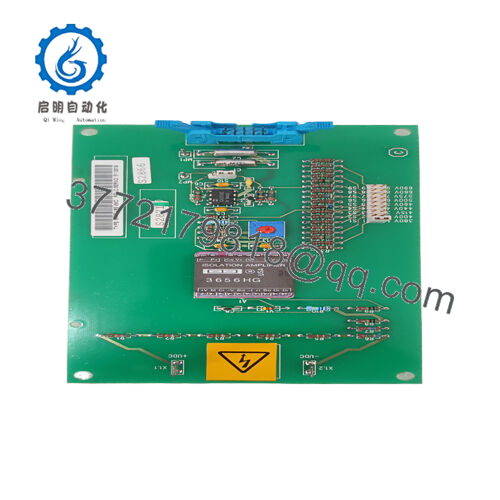

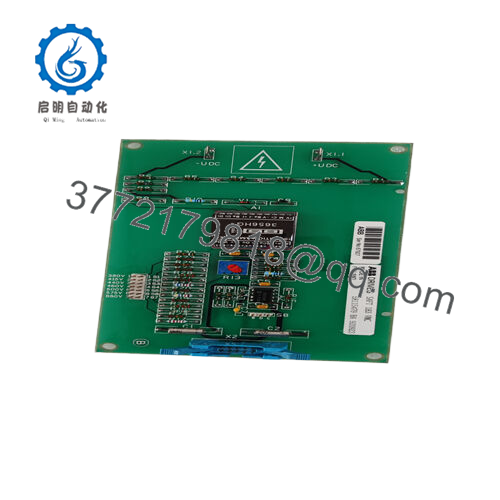

- SAFT183VMC

- SAFT183VMC

Product Introduction & Positioning

The ABB SAFT183VMC is a certified safety controller module that forms part of ABB’s portfolio of safety products, designed to deliver SIL 3 (Safety Integrity Level) compliant performance according to IEC 61508. It integrates smoothly with ABB’s overall automation system to provide monitoring and control of safety inputs and outputs with high reliability. This controller supports communication via PROFIBUS DP and Modbus RTU, enabling efficient interaction with other control system components. Engineers use the SAFT183VMC to implement advanced safety logic and diagnostics in safety-critical applications, benefiting from a compact design and comprehensive certification that assures confidence in both machine and personnel safety.

Key Technical Features & Functional Benefits

The SAFT183VMC features eight safety inputs and four relay safety outputs, allowing it to monitor a wide range of safety devices such as emergency stop buttons, safety light curtains, and safety interlocks. It offers fast processing speeds (100 ns cycle time) for real-time safety signal handling and supports continuous self-diagnostics to detect faults within the module or connected devices. Its robust communication interfaces ensure secure and timely data exchange within distributed automation environments, enhancing coordinated safety response.

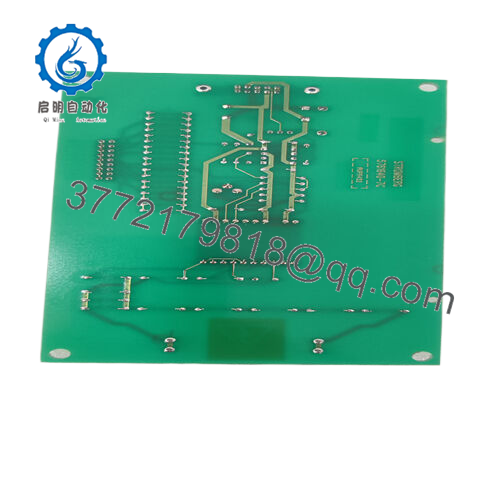

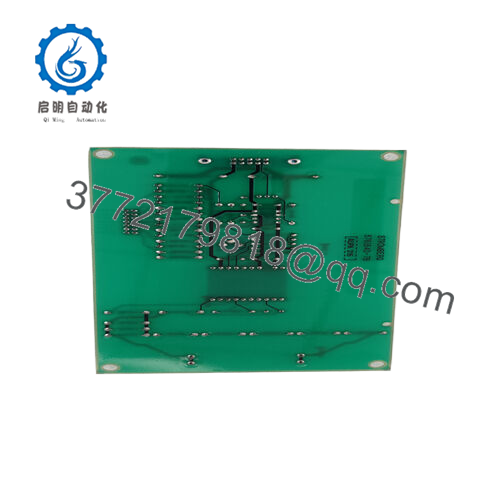

The module is designed for mounting on standard DIN rails, ensuring easy integration into existing systems and control panels. The low power consumption and durable construction make it suitable for continuous operation in industrial environments. Combined with ABB’s configuration and diagnostic software tools, the SAFT183VMC simplifies setup, monitoring, and maintenance processes while meeting stringent safety and performance criteria.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | SAFT183VMC |

| Brand | ABB |

| Type | Safety Monitoring and Control Module |

| Safety Inputs | 8 safety inputs |

| Safety Outputs | 4 safety relay outputs |

| Communication Protocols | PROFIBUS DP, Modbus RTU |

| Processing Speed | 100 ns cycle time |

| Power Supply Voltage | 24 V DC ± 20% |

| Power Consumption | ≤ 5 W |

| Mounting | DIN Rail |

| Safety Integrity Level | SIL 3 (IEC 61508 certified) |

| Operating Temperature | -25°C to +60°C |

| Dimensions (W x H x D) | Approx. 84 mm x 45 mm x 120 mm |

| Protection Rating | IP20 |

Related Modules or Compatible Units

SAFT181VMC – Smaller safety controller module with fewer inputs/outputs for less complex applications.

SAFT182VMC – Safety module offering additional I/O configurations.

PM864 HI – High integrity process control CPU compatible with ABB safety modules.

SM810 Safety CPU – Safety CPU module kit for high-integrity control systems.

CI853 Communication Interface – Network interface supporting PROFIBUS and Modbus communication.

Tina Adaptors – Accessories to connect external safety devices to ABB safety controllers.

Installation Notes & Maintenance Best Practices

Installation of the ABB SAFT183VMC demands secure DIN rail mounting inside control panels protected from dust and moisture. Proper wiring with shielded cables and grounding is critical to ensure signal integrity and reduce electromagnetic interference. Clear labeling and structured cabling support easier maintenance and troubleshooting.

Routine maintenance includes periodically checking signal input and output integrity, inspecting relay operation, and performing diagnostics via ABB’s configuration software. Firmware updates are recommended to maintain compliance with evolving safety standards and keep diagnostic functions current. Regular review of safety logs and event histories enhances system reliability and safety compliance.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626