Description

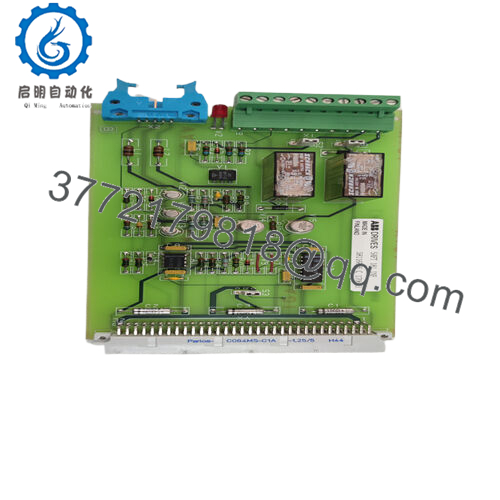

In the intricate web of industrial automation, where seamless data exchange between field devices and central controllers can spell the difference between fluid operations and fragmented workflows, engineers often contend with integration silos that stifle scalability and expose systems to communication breakdowns. These hurdles are particularly acute in legacy DCS environments or hybrid setups, such as those in pulp and paper mills or semiconductor fabs, where expanding I/O capabilities without invasive rewiring risks signal latency or protocol mismatches, ultimately undermining process control precision. The ABB SAFT181INF (SAFT 181 INF) confronts these realities as a dedicated interface board, forging reliable bridges for information flow within ABB’s SAFT series architecture to bolster high reliability and modular connectivity. Visualize a bottling plant scaling up sensor arrays for fill-level monitoring: disparate fieldbus signals could overwhelm legacy buses, leading to jittery feedback loops or dropped packets that halt lines, but the ABB SAFT181INF intervenes by normalizing inputs into a cohesive I/O signal stream, enabling tighter synchronization and reduced troubleshooting cycles. It’s vital in scenarios demanding robust process control, like fault-tolerant networks in pharmaceutical blending, where every interface must uphold data integrity amid varying loads. This board advances objectives such as streamlined diagnostics and future-ready expansions, curtailing the downtime costs tied to mismatched hardware in industrial automation. Far from a mere connector, the ABB SAFT181INF embodies a consultative pivot toward resilient architectures, where enhanced signal reliability empowers proactive oversight rather than perpetual patching, aligning with the pragmatic needs of teams navigating evolving regulatory and throughput pressures.

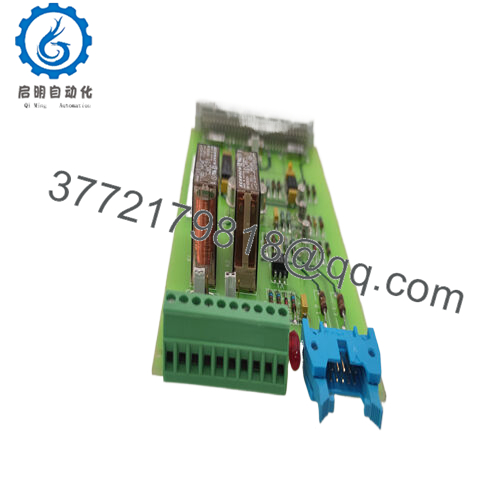

The ABB SAFT181INF operates at the nexus of field and supervisory layers in ABB’s SAFT or Advant OCS control frameworks, serving as an interface board that decodes and routes analog/digital signals from remote I/O modules to the host processor, ensuring low-jitter handoffs in the overall automation stack. It embeds into backplane assemblies alongside CPUs like the SAFT 185 or communication carriers, where it leverages the system bus to distribute conditioned data—handling tasks from voltage translation to isolation buffering without introducing ground loops that plague noisy environments. In a practical rollout, you’d slot it into a rack-mounted enclosure, linking field terminations via screw or pluggable connectors to upstream logic units, supporting up to multiple channels of mixed-signal traffic while integrating diagnostics for real-time parity checks. This fosters interoperability with protocols like Modbus RTU or Profibus DP, allowing it to mesh with diverse vendor gear in DCS migrations, and redundancy schemes where a mirrored ABB SAFT181INF shadows primaries for seamless cutovers during faults. Positioned mid-stack, it shields higher-level controllers from raw field variances, like EMI from motors, by applying galvanic isolation that preserves I/O signal fidelity for accurate alarming or setpoint adjustments. For diagnostics, embedded status lines feed into central HMIs, spotlighting issues like channel faults via simple polling, without derailing core computations. This makes the ABB SAFT181INF a linchpin in backplane-centric designs, where it not only conveys data but also fortifies the architecture against expansion-induced strains, promoting a layered resilience that scales from standalone cabinets to enterprise-wide process control webs.

| Specification | Details |

|---|---|

| Model Number | SAFT181INF (SAFT 181 INF) |

| Brand | ABB |

| Type | Interface Board |

| Input Voltage | 24 V DC |

| Operating Temp Range | -10°C to +60°C |

| Mounting Style | Backplane or Rack |

| Dimensions | 150 mm x 50 mm x 100 mm |

| Weight | 0.25 kg |

| Interface/Bus | SAFT System Bus |

| Compliance | CE, RoHS, EMC |

| Supported Protocols | Modbus, Profibus DP |

| Typical Power Draw | 4 W |

Incorporating the ABB SAFT181INF fortifies your control ecosystem with an interface layer crafted for steadfast translation, where its isolation tactics avert noise-induced anomalies that might skew actuator timing, yielding steadier cycles and fewer variance-induced rejects in precision-driven runs. This reliability cascades into operational steadiness, letting crews dial in optimizations like predictive analytics on cleaner datasets, rather than sifting through error logs that balloon support tickets.

- SAFT181INF

- SAFT181INF

Ease of weaving into extant setups stands out too, as standardized pinouts and bus alignment shave hours off integration proofs, enabling parallel testing that accelerates go-lives without inflating validation budgets. From a maintenance lens, its diagnostic transparency spotlights drifts early—say, via threshold alerts—trimming inspection scopes to targeted scans, which in turn bolsters mean time between failures and frees technicians for strategic upgrades over rote checks.

Fundamentally, the ABB SAFT181INF unlocks sustained agility in flux-prone industrial automation realms, where dependable interfaces underpin not only current efficiencies but the latitude to layer in AI-driven controls, all sans the entanglement of bespoke adapters or cascading reworks.

In pulp and paper production, the ABB SAFT181INF interfaces stock preparation sensors with DCS cores, where it sustains high reliability for moisture and thickness profiling amid steamy, fibrous environs, ensuring process control environments deliver uninterrupted web speed adjustments for minimal waste in continuous rolls.

Semiconductor wafer fabs deploy the ABB SAFT181INF to link etch chamber I/O to oversight logic, championing critical system uptime against cleanroom static and rapid cycle demands, where precise signal routing prevents alignment drifts that could scrap batches in nanoscale etching ops.

Food and beverage lines harness the ABB SAFT181INF for packaging integrity checks, integrating vision systems into PLC backplanes under washdown conditions, supporting fast data cycles that lock in fill accuracies and seal validations for compliant, high-volume throughput.

SAFT185TBC – Terminal block companion for expanded field wiring in SAFT racks.

SAFT188IOC – I/O connection board variant for denser signal aggregation.

SAFT187CON – Control interface add-on for enhanced protocol bridging.

CI532 – Communication module that pairs with SAFT181INF for fieldbus extensions.

PM511 – Processor unit integrating SAFT interfaces for MOD 300 upgrades.

AI810 – Analog input module buffered through SAFT181INF for noise rejection.

DO820 – Digital output counterpart for actuator signaling in hybrid setups.

3BSE008516R1 – Legacy interface alternative with firmware for older OCS ties.

Before slotting in the ABB SAFT181INF, audit your backplane’s slot pitch and voltage rails to the 24 V DC norm, guarding against shorts from mismatched adapters, and map channel assignments against your I/O manifest to preempt crosstalk in multi-board arrays. Ambient scouting matters—keep it clear of radiant heat sinks to stay under 60°C, and affirm enclosure seals hit IP54 for dusty floors, while a firmware handshake test with the host CPU via ABB’s loader tool nips boot loops in the bud.

Sustaining it boils down to pattern watches: ping status registers monthly through the system console for anomaly spikes, and eyeball connectors post-vibration events for seating firmness, as loose ties amplify attenuation over runs. Half-yearly loop-back trials with a signal generator validate throughput sans degradation, and a soft wipe-down of contacts with isopropyl curbs oxidation in humid bays. These rituals position the ABB SAFT181INF as a quiet workhorse, surfacing quirks before they thread into outages and preserving your network’s cadence with judicious effort.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626