Description

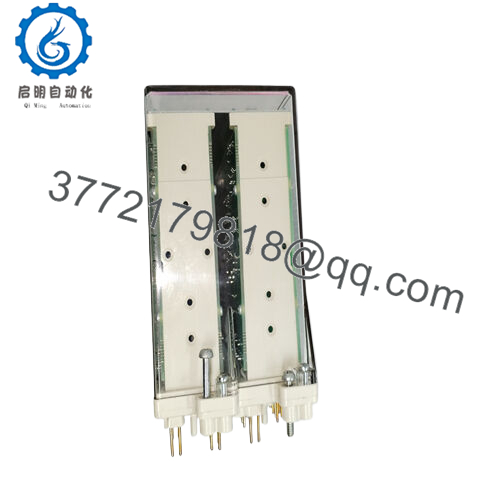

| Model | RXDS 4 |

| Brand | ABB |

| Type | Residual Current Device |

| Rated Voltage | 230V AC / 400V AC (depending on model) |

| Rated Current Range | 16A – 125A |

| Residual Current Sensitivity | 30 mA, 100 mA, 300 mA (selectable models) |

| Tripping Time | < 30 ms at rated residual current |

| Mounting | DIN – rail mounting (35mm) |

| Dimensions | 72mm x 90mm x 60mm (W x H x D) |

| Weight | 0.3 kg |

| Environmental Rating | IP20 (suitable for indoor use) |

| Certifications | IEC 61009 – 1, CE |

RXDS 4

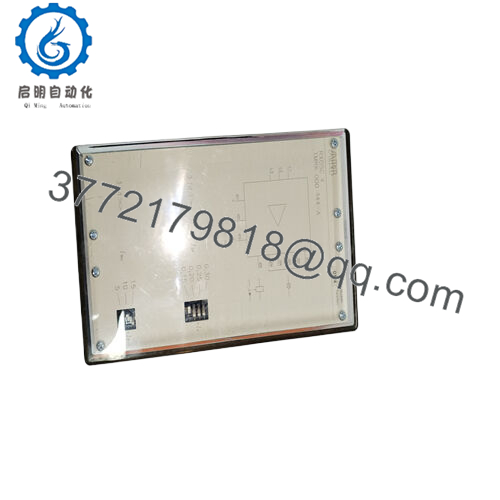

The ABB RXDS 4 is engineered to detect and respond to residual currents, which are the unbalanced currents that flow through the protective earth conductor in an electrical circuit. As a vital part of electrical safety infrastructure, it combines high – sensitivity current detection capabilities with rapid tripping mechanisms. This device acts as a vigilant guardian, constantly monitoring the electrical current in the circuit. When it detects a residual current above its set threshold, it quickly interrupts the circuit, preventing potentially dangerous electrical situations from escalating.

RXDS 4

The ABB RXDS 4 integrates seamlessly with different types of electrical panels, be it in a standard industrial control panel or a modular distribution board in a commercial building. Its compact design allows for easy installation even in spaces with limited room, while still providing reliable protection. What makes the ABB RXDS 4 particularly valuable is its ability to operate accurately in both single – phase and three – phase electrical systems, making it versatile for a wide range of applications.

RXDS 4

Main features and advantages:

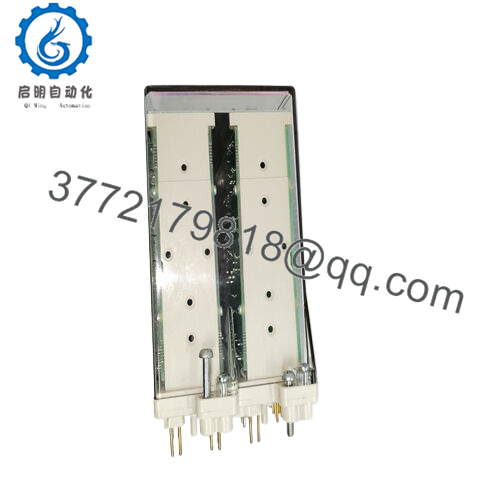

The ABB RXDS 4 offers high – precision residual current detection with a sensitivity down to 30 mA, ensuring that even the smallest abnormal currents are detected promptly. It has a fast tripping time, typically within milliseconds, which is crucial for preventing electric shocks and minimizing damage to equipment in case of a fault. The device supports a wide range of rated currents, making it suitable for applications with different load requirements, from small – scale electrical setups to large – capacity industrial machinery.

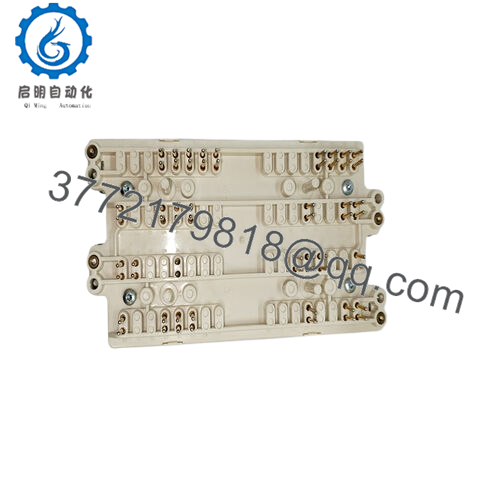

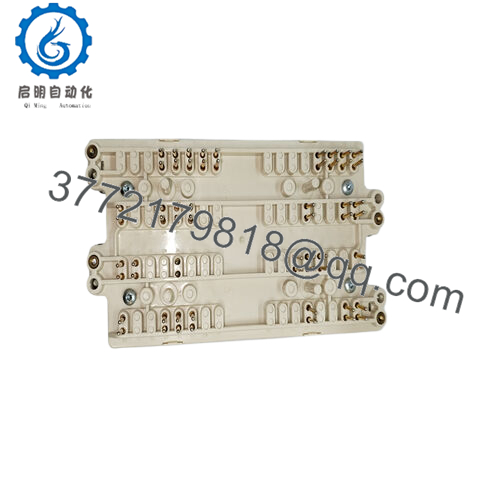

Hardware design features include a robust enclosure that can withstand harsh environmental conditions, with an operating temperature range from – 25°C to + 55°C. This makes it suitable for installation in areas with extreme temperatures, such as outdoor electrical enclosures in industrial plants or in unconditioned storage areas in commercial facilities. The connection terminals are designed for easy and secure wiring, allowing for quick installation and maintenance. Additionally, the device is designed to be vibration – resistant, ensuring stable operation in environments with mechanical vibrations, like those found in industrial manufacturing plants.

RXDS 4

Application areas:

In the complex landscape of electrical distribution systems, safeguarding personnel and equipment from the perils of electrical faults, especially those related to residual currents, is of utmost importance. Industries such as manufacturing, where high – power machinery operates continuously, and commercial buildings with a multitude of electrical appliances, face the challenge of ensuring electrical safety in environments with diverse loads and potential for electrical malfunctions. Whether protecting workers from electric shocks in industrial workshops or preventing property damage due to electrical fires in shopping malls, reliable residual current protection devices are essential.

This is where the ABB RXDS 4 shines. It is a state – of – the – art residual current device designed to provide comprehensive protection in various electrical installations. In industrial settings, it can be installed in control panels of large – scale manufacturing equipment, monitoring and swiftly reacting to any abnormal residual currents that could indicate a fault in the machinery’s electrical system. In commercial buildings, it serves as a crucial component in the electrical distribution network, protecting multiple circuits that power lighting, HVAC systems, and other electrical amenities. With a track record of reliability in demanding electrical applications, the ABB RXDS 4 has become a trusted choice for electrical engineers, facility managers, and safety – conscious installers worldwide.

Related products:

ABB S4 – related Control Panels – These can be integrated with the ABB RXDS 4 to provide comprehensive electrical protection in industrial control applications.

ABB DS204 AC – C40/0.03 – Another residual current – related device that can complement the ABB RXDS 4 in more complex electrical protection setups, especially in scenarios where different levels of protection are required.

ABB QA/S4.64.1 Energy Analyzer – Can work in tandem with the ABB RXDS 4 in commercial building electrical systems, where energy monitoring and safety protection are both important. The analyzer can help in understanding power consumption patterns, while the ABB RXDS 4 ensures electrical safety.

ABB F204A – 40/0.3 – This device can be compared with the ABB RXDS 4 in terms of its protective capabilities, and in some cases, can be used in parallel or as a backup in electrical installations where high – reliability protection is needed.

Installation and maintenance:

Before installing the ABB RXDS 4, carefully check the electrical panel where it will be installed. Ensure that the panel has sufficient space for the device and that the DIN – rail is in good condition. Verify that the electrical system’s voltage and current ratings are compatible with the ABB RXDS 4 model being installed. Also, make sure to turn off the power supply to the circuit where the device will be installed to prevent any electrical accidents during installation.

During installation, firmly mount the ABB RXDS 4 on the DIN – rail, ensuring that it is securely fastened. Connect the incoming and outgoing electrical wires to the appropriate terminals, following the wiring diagram provided with the device. Pay close attention to the wire gauges and ensure that they are suitable for the rated current of the circuit. After installation, perform a visual inspection of all connections to make sure they are tight and secure.

Other ABB product models:

ABB 3BHE044249R0003

ABB 3BHE046836R0101

ABB 3BHE046836R0102 GFD563A102

ABB 3BHL000250P0002

ABB 3BHL000391P0101 5SHX1445H0001

ABB 3BHL000406P0009

ABB 3BHL000406P0103

ABB 3BHL000519P0001

ABB 3BHL000734P0003

ABB 3BHL000986P0006

ABB 3BHL001433P0001

ABB 3BHT300011R1

ABB 3BSE003816R1 SC520

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004160R1 PFTL101A 0.5KN

ABB 3BSE004172R1 PFTL101A-2KN

ABB 3BSE004172R1 PFTL101A 2KN

ABB 3BSE018135R1

ABB 3BSE019050R200 PFTL301E-0.2kN

ABB 3BSE030928R1 SM810K01

ABB 3BSE042235R2

ABB 3BSE042236R1 PP865

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE042237R2 PP836A

ABB 3BSE043660R1 CI867K01

ABB 3BSE056899R1 CI873K01

ABB 3BSE066490R1

ABB 3BSE076939R1 PM866AK01

ABB 3BSE091722R1 LD 810HSE EX

ABB 3BSE092689R1

ABB 3BSE092689R1 CI867AK01

ABB 3BSE092978R1 PP881

ABB 3BUS208797-001

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626