Description

What This Product Solves

The ABB PPD539A102 3BHE039770R0102 is an advanced excitation control processor designed for precise regulation and management of excitation systems in power generation and industrial motor applications. It meets the critical need for maintaining stable, efficient excitation current to synchronous generators or motors, which directly affects power quality, operational safety, and equipment longevity. The module’s real-time control capabilities help engineers ensure consistent voltage and reactive power, reducing risk of downtime and improving overall system stability.

This controller is essential in industries such as power plants, renewable energy, and heavy industrial processes where excitation control impacts core performance. Keywords like “industrial automation,” “excitation control,” “power system stability,” and “real-time regulation” reflect its role in high-demand automation environments.

How the Product Works & Fits into a System

The ABB PPD539A102 3BHE039770R0102 incorporates a powerful digital signal processor and advanced algorithms to regulate the excitation current accurately. It supports multiple control modes such as constant voltage and constant power factor, adapting to variable load and operating conditions for optimal performance. The controller offers diagnostics, fault protection (overvoltage, undervoltage, overcurrent), and real-time monitoring to prevent system failures.

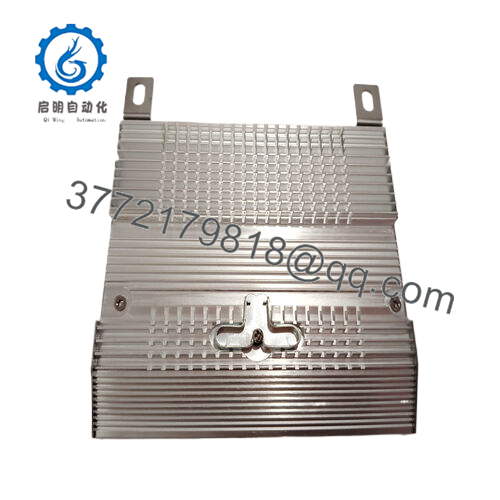

Physically, it features a robust, compact design (about 390 mm × 295 mm × 100 mm) suitable for DIN rail or cabinet mounting, with operating temperature ranges suitable for harsh industrial environments. Communication capabilities include Ethernet and protocols like Modbus and Profibus, allowing seamless integration into SCADA and automation networks for centralized control and data acquisition.

Technical Highlights Summary (Table)

| Specification | Details |

|---|---|

| Model Number | PPD539A102 / 3BHE039770R0102 |

| Brand | ABB |

| Type | Excitation Control Processor |

| Power Supply | 18-30 V DC (24 V rated) |

| Communication Interfaces | Ethernet, Modbus, Profibus |

| Control Modes | Constant voltage, power factor, others |

| Protection | Overvoltage, undervoltage, overcurrent |

| Operating Temp Range | -20°C to +60°C |

| Dimensions | 390 mm × 295 mm × 100 mm |

| Mounting Style | DIN Rail / Control cabinet |

ABB PPD539A102 3BHE039770R0102

Real-World Benefits

The ABB PPD539A102 3BHE039770R0102 enables highly accurate excitation current control, critical for maintaining voltage and reactive power stability in power systems. Its modular design with advanced diagnostics and fault protection reduces downtime and enhances equipment safety. Operators benefit from easy integration with existing control systems, simplified maintenance, and the ability to adapt to varying operational demands through multiple control modes.

Its rugged construction ensures reliable operation in demanding industrial conditions, supporting continuous power generation and efficient motor operation, thus increasing plant availability and reducing operating costs.

Typical Use Cases

This processor is fundamental in power generation plants, substations, and heavy industry applications such as metallurgy, mining, and chemical processing where synchronous generator excitation must be continuously managed. It is also employed in renewable energy systems like wind and hydropower to optimize generator performance and improve grid stability.

The ABB PPD539A102 3BHE039770R0102 supports critical automation functions requiring accurate, real-time regulation of complex excitation systems under diverse operating conditions.

Compatible or Alternative Products

PPD539A102 3BHE039770R0102 – ABB excitation control processor module.

GFD563A101 3BHE046836R0101 – Industrial Ethernet control and communication module.

216AB61 HESG324013R100 – Digital output module for protection and automation.

07KT98C GJR5253100R028 – Programmable automation controller unit.

UFC760BE142 3BHE004573R0142 – High-voltage interface module for automation systems.

Setup Notes & Maintenance Insights

Installation requires ensuring stable 24 V DC power supply and mounting space compliant with DIN rail or control cabinet standards. Communication configurations should match existing network protocols (Ethernet, Profibus) to guarantee seamless integration.

Routine maintenance includes firmware updates, verification of control loop accuracy, and monitoring of fault logs for proactive troubleshooting. Regular inspections of connectors and environmental conditions help maintain reliable excitation control function over long-term operation.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626