Description

In the fast-paced domain of industrial automation, where drive systems falter under erratic loads or communication delays—consider a conveyor line in a packaging plant stuttering from imprecise speed regulation, or a pump station in water treatment battling torque ripples that spike energy use and wear—core control modules often become the weak link. These setups crave stable, responsive logic to synchronize motors and processes without constant oversight, yet legacy boards struggle with real-time demands, risking inefficiencies or outright halts in process control. The ABB PPC907BE 3BHE024577R0101 enters as a high-performance AMC 34 control board, rooted in ABB’s AC 800+ platform, to deliver precise I/O signal management and high reliability for variable speed drives, ensuring seamless operation amid variable conditions.

This board proves crucial in mid-scale applications like retrofitting ACS series drives, where modular scalability sidesteps full system teardowns, or in servo-heavy assembly lines needing fault-tolerant execution to maintain throughput. In a metals processing facility, for example, it handles fluxing harmonics from induction motors, stabilizing current loops to prevent overcurrents that could derail shifts. For renewable tie-ins, such as solar inverters, the ABB PPC907BE 3BHE024577R0101 adapts to intermittent profiles via robust diagnostics, upholding signal integrity without nuisance faults. It’s a go-to for engineers targeting system stability in EMI-rich floors or thermal-variable enclosures, where it isolates noise and supports redundancy to avert single-point vulnerabilities.

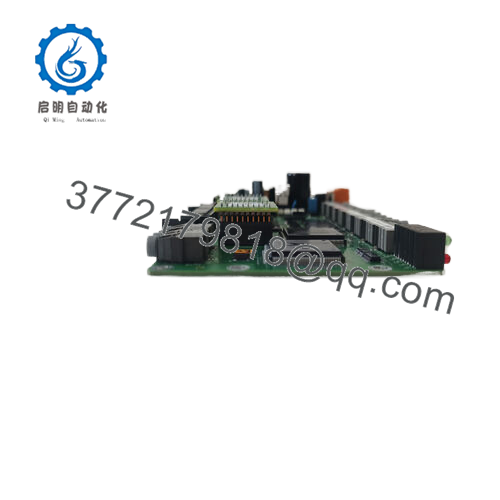

PPC907BE 3BHE024577R0101

PPC907BE 3BHE024577R0101

At heart, it champions your priorities: flexible integration with ABB drives and motors, from soft starters to high-torque servos, while embedding self-monitoring to flag drifts early. In excitation systems for generators, it fine-tunes reactive power distribution, minimizing voltage swings in paralleled ops. For teams modernizing brownfield sites, the ABB PPC907BE 3BHE024577R0101 bridges to Ethernet-native networks, cutting reconfiguration time and boosting high-reliability outputs. By centering on adaptive control, it alleviates the grind of mismatched hardware in industrial automation, redirecting efforts to fine-tuning performance rather than patching gaps.

Tying the ABB PPC907BE 3BHE024577R0101 into your architecture frames it as the agile nucleus for drive-centric stacks, where it processes analog and digital I/O signals to orchestrate motor commands within ABB’s ACS ecosystems. This AMC 34 board slots into backplane assemblies via edge connectors, extending the AC 800M’s logic layer to field-level effectors like VFDs and encoders, while upward links feed supervisory HMIs for holistic oversight. In the hierarchy, it perches mid-stack—above raw sensors but below orchestration software—leveraging multi-core processing for parallel tasks like PID tuning and fault logging.

In motion, it interfaces via Ethernet, CANopen, or Profibus for real-time polling, syncing torque references and feedback loops with sub-ms latency to tame oscillations in multi-axis setups. Built-in diagnostics scan for overvoltages or comms timeouts, routing alerts through LEDs or software hooks into Control Builder for predictive tweaks—vital in distributed process control where remote access trumps on-site dives. Redundancy pairs it with duplicate boards for hot-standby, ensuring failover without process hiccups, while expansion slots accommodate add-ons for denser I/O in hybrid zones.

This versatility shines in drive architectures: daisy-chain it with power modules for ACS880 cabinets, configure via USB for custom curves, and validate via simulation runs that mirror live loads. For backplane users, the ABB PPC907BE 3BHE024577R0101 streamlines onboarding, morphing rigid controls into extensible frameworks that evolve with demands, from single-motor tweaks to plant-wide synchronization.

| Specification | Details |

|---|---|

| Model Number | PPC907BE 3BHE024577R0101 |

| Brand | ABB |

| Type | AMC 34 Control Board |

| Input Voltage | 24 VDC |

| Operating Temp Range | -25°C to 55°C |

| Mounting Style | DIN Rail / Backplane |

| Dimensions | 40 x 22.5 x 11.5 mm |

| Weight | 0.5 kg |

| Interface/Bus | Ethernet, CANopen, Profibus |

| Compliance | CE, RoHS |

| Supported Protocols | Modbus, Profibus DP |

| Typical Power Draw | 5 W |

Integrating the ABB PPC907BE 3BHE024577R0101 yields steadfast drive harmony, with its multi-core engine sustaining cycle times under 1 ms for loops that demand unyielding torque precision—crucial in variable-load scenarios where lags compound into material waste or safety lapses. This steadiness curbs energy spikes by optimizing vector control, easing strain on upstream supplies and extending motor life in cyclic duties, all while its rugged casing shrugs off vibrations that degrade lesser boards.

The integration edge compounds through native ACS compatibility, where it reuses cabling and configs to halve deployment spans, letting crews pivot from wiring woes to validation runs. Maintenance sharpens further with embedded health checks that log transients preemptively, trimming downtime diagnostics from shifts to spot-checks via remote portals—fostering a leaner workflow that scales without ballooning headcount. Engineered for longevity in grimy or humid bays, it holds calibration across thermal swings, deferring swaps and aligning with capex cycles in sustained ops.

Forward-looking, this board trims holistic costs by sipping just 5 W, lightening cabinet thermals and UPS loads for greener footprints, while scalable slots future-proof against I/O creep. In reliability-driven realms, the ABB PPC907BE 3BHE024577R0101 acts as a force multiplier, weaving adaptive safeguards into drive chains that weather transients, ensuring your industrial automation pulses with resilient efficiency.

In manufacturing plants, the ABB PPC907BE 3BHE024577R0101 governs variable speed drives for assembly robots, processing fast I/O signals amid dusty floors to guarantee continuous uptime in process control environments where sync slips halt lines. Its high-reliability torque loops adapt to payload shifts, minimizing jams.

Power generation sites embed it in excitation controls for synchronous generators, regulating reactive flows under grid fluctuations—delivering precise voltage stability in harsh, high-vibration turbine halls for critical system uptime. Chemical processing leverages it for pump servos in corrosive zones, supporting modular expansions for batch dosing with unerring flow fidelity. These integrations position the ABB PPC907BE 3BHE024577R0101 as a cornerstone for demanding, uptime-vital industrial automation, where drive mastery meets endurance.

PPC905BE 3BHE010852R0101 – Entry-level variant for lighter drive duties with basic I/O scaling.

AMC 35 3BHE024578R0101 – Upgraded board with enhanced redundancy for safety-integrated loops.

PPC907AE 3BHE024576R0101 – Analog-focused predecessor for legacy ACS retrofits.

3BHE024579R0101 – High-density I/O companion for multi-motor expansions.

PPC908BE 3BHE024580R0101 – Faster processor option for high-throughput servo networks.

AMC 34 Kit 3BHE024581R0101 – Diagnostic add-on module for advanced fault simulation.

3BHE010853R0101 – Compact interface extender for fieldbus-heavy setups.

PPC906BE 3BHE024575R0101 – Cost-optimized model for standard soft-start applications.

Before rack-fitting the ABB PPC907BE 3BHE024577R0101, map backplane pinouts against your ACS chassis—mismatches in edge slots can ghost signals, so prototype a bench test if blending gens. Gauge 24 VDC purity for <5% ripple, as noise bleeds into analog paths; isolate with ferrites if your supply hums from nearby inverters. Prime firmware through ABB’s loader to match AC 800+ revisions, dodging boot loops that stall configs.

In the long haul, stewardship stays grounded to sidestep overhauls. Every other week, eye status LEDs for heartbeat and fault pulses—uniform glows affirm readiness, but intermittents flag a config reload to purge glitches. Biannually, probe comm ports with loopback plugs to vet Profibus integrity, and cycle thermal stress tests per guide specs to benchmark drift under load. For oily or particulate-laden spots, a non-static wipe of contacts quarterly wards corrosion, coupled with torque audits on DIN clips to defy settling. Rooted in ABB’s service playbook, this regimen casts the ABB PPC907BE 3BHE024577R0101 as a durable partner, exacting scant effort for enduring drive poise.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626