Description

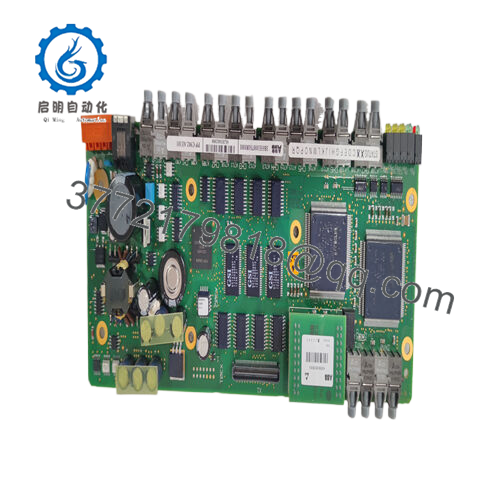

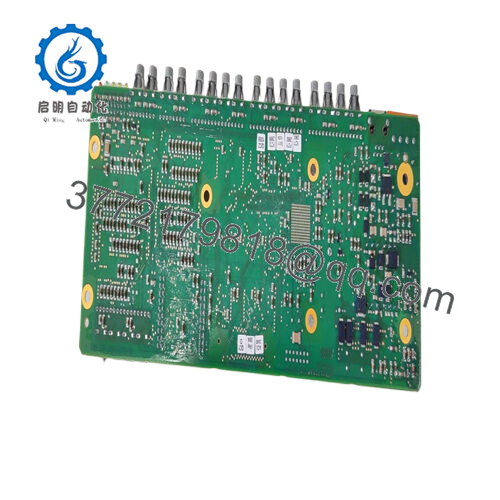

- Product Model: ABB PPC902CE101

- Product Brand: ABB

- Product Series: ABB DCS Controller Series

- Product Features:

- High-speed central processor for complex control tasks

- Seamless integration with ABB distributed control systems

- Designed for long-term reliability in demanding industrial environments

- Flexible configuration and wide compatibility with automation modules

Applications & Industry Context

In modern industrial automation, seamless control and reliable data handling are the backbone of efficiency. The ABB PPC902CE101 plays a critical role in industries where complex processes must be monitored and controlled without interruption. Plants in power generation, oil and gas, chemical refining, pulp and paper, and advanced manufacturing rely on such processors to keep operations stable, optimized, and safe.

Consider a large-scale power plant where hundreds of input signals must be read simultaneously, analyzed, and converted into control commands. Without a capable processor like the ABB PPC902CE101, the risk of downtime, unstable regulation, or delayed responses increases significantly. The PPC902CE101 is built to thrive in these high-demand situations, ensuring precise execution of automation tasks even under heavy loads.

Its design reflects ABB’s long experience in distributed control systems (DCS). In industries like oil refining, sudden process variations can lead to safety risks and product quality issues. The PPC902CE101 helps mitigate such risks by executing deterministic logic and maintaining robust communication between different process units. This makes it not just a processing module, but a cornerstone of operational reliability.

In pulp and paper mills, where process variability is high and margins are tight, this processor assists operators by enabling advanced control loops that improve efficiency. Its ability to maintain tight integration with ABB controllers ensures operators have a consistent and trustworthy automation backbone.

PPC902CE101

PPC902CE101

Technical Features & Benefits

The ABB PPC902CE101 is more than a standard control board — it’s engineered as a high-availability processor with an emphasis on performance, scalability, and fault tolerance. Among its many features are its high-speed CPU, which ensures rapid processing of real-time tasks, and its built-in interfaces that allow seamless communication with multiple subsystems.

One standout benefit is its reliability. The module is engineered to operate continuously in harsh conditions, from fluctuating temperatures to electrical noise environments common in industrial plants. ABB’s quality control ensures each unit maintains consistent operation for years, minimizing unexpected failures.

Compatibility is another strong point. The ABB PPC902CE101 integrates smoothly with other ABB DCS modules, reducing the complexity of system upgrades or replacements. Engineers who have worked with ABB systems value this plug-and-play compatibility, as it shortens downtime during installation and simplifies lifecycle management.

The processor also provides scalability. Whether used in a mid-sized chemical plant or a large-scale refinery, it adapts to varying loads. Additional modules can be incorporated without overhauling the central controller, making it a future-proof investment.

Energy efficiency has also become a priority in automation, and ABB ensures that this processor minimizes energy consumption while maintaining performance. This is especially beneficial in large facilities where hundreds of modules may be operating simultaneously, leading to long-term cost savings.

Technical Specifications

| Specification | Details |

|---|---|

| Product Model | ABB PPC902CE101 |

| Brand | ABB |

| Series | ABB DCS Controller Series |

| Processor Type | High-performance central control processor |

| Communication Interfaces | Multi-bus support for system integration |

| Operating Environment | Designed for industrial harsh conditions |

| Power Supply | Optimized for low energy consumption |

| Reliability Rating | High availability, long operational life |

| Integration | Seamless with ABB DCS systems |

| Application Scope | Power, oil & gas, chemical, pulp & paper, manufacturing |

| Maintenance | Hot-swappable, field-serviceable |

| Dimensions | Compact module design for rack systems |

Installation & Maintenance Insights

Installing the ABB PPC902CE101 is straightforward for engineers familiar with ABB’s DCS architecture. The module is designed for rack-based systems, allowing technicians to slide it into place without complex wiring changes. Thanks to its hot-swappable design, replacements can be made while the system is powered, which minimizes downtime.

During installation, ensuring proper grounding is key, especially in environments with high electrical noise. This helps prevent data corruption and extends the life of the module. ABB provides clear documentation, but in practice, field engineers note that following standardized cable routing and labeling procedures greatly simplifies future troubleshooting.

Maintenance is minimal, which is one of the reasons plant operators appreciate this unit. Routine visual checks for dust accumulation and periodic firmware updates are usually sufficient to keep the module in optimal condition. In environments prone to vibration or high temperatures, additional care may be needed to verify secure seating of the module in its rack.

Product Role & System Fit

Within ABB’s automation architecture, the ABB PPC902CE101 functions as the brain of the operation. It coordinates signals from input/output modules, processes real-time data, and executes logic that drives actuators, valves, and machinery. Its role is central: without a functioning processor, other modules cannot communicate effectively or maintain synchronization.

The processor also bridges different layers of control. It links operator workstations with field devices, ensuring commands are executed correctly and feedback is relayed instantly. For engineers designing a system, its compatibility with ABB’s range of control modules means fewer integration issues and faster commissioning.

Another aspect of system fit is redundancy. Many facilities deploy dual-processor configurations, where a second PPC902CE101 runs in parallel, ready to take over instantly if the primary unit encounters a fault. This strategy underscores the processor’s role in ensuring continuous operations.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626