Description

Real-World Use & Application Scenarios

The ABB PPC902AE101 3BHE010751R0101 is widely used in industrial automation and power system control environments that demand robust processing power for signal modulation, communication, and control tasks. This module is often found in critical infrastructure such as power plants, heavy manufacturing, and large-scale process industries where reliable and precise communication of control signals is essential. It is particularly applicable in control rooms handling excitation control, real-time data processing, and network communication.

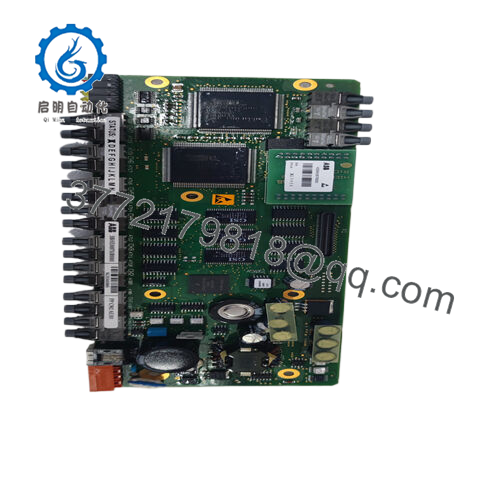

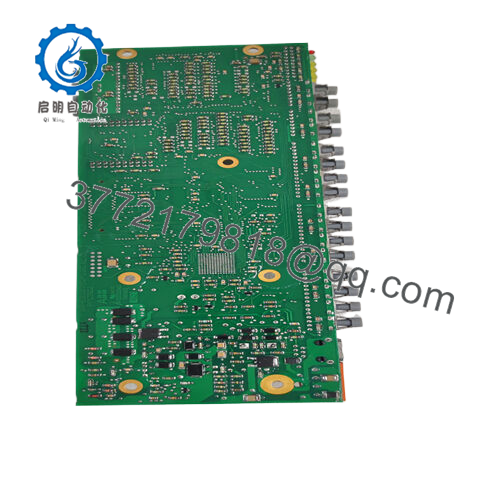

PPC902AE101 3BHE010751R0101

The ABB PPC902AE101 3BHE010751R0101 supports complex control system architectures requiring phase modulation of signals to ensure accurate transmission across communication networks, making it valuable in distributed control and monitoring systems in harsh industrial environments.

Product Introduction & Positioning

The ABB PPC902AE101 3BHE010751R0101 is a phase modulation processor module designed for advanced signal processing within ABB’s automation platforms. It converts input signals by modulating their phase, thus enabling precise information transmission suited for industrial communication systems. This module fits into ABB’s control system architecture as a communication and signal processing unit, supporting high-speed data handling and command execution. Engineers integrate the PPC902AE101 3BHE010751R0101 to enhance robustness and signal fidelity in control networks, benefiting from its compatibility with multiple industrial protocols and scalable system design. Its role is pivotal in facilitating efficient, synchronized operations and network-wide data exchange.

Key Technical Features & Functional Benefits

Powered by a high-performance dual-core processor running at 1.2 GHz, the ABB PPC902AE101 3BHE010751R0101 delivers rapid processing speeds with Boolean control execution times around 0.1 ms, enabling real-time reaction and control. It includes 1 GB of RAM and 512 MB of flash memory to support complex algorithms and stable program storage. The hardware design ensures durability with industrial-grade components and efficient thermal management, making it suitable for continuous use in demanding environments.

Communication options include dual high-speed Ethernet ports and multiple digital I/O channels supporting 24 V DC signals, giving it versatile connectivity for diverse sensor and actuator integration. Its phase modulation capability allows the module to manage signal integrity and noise reduction effectively in communication pipelines. The compact design and advanced processing make it a reliable asset in mission-critical control systems requiring low latency and high availability.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | PPC902AE101 3BHE010751R0101 |

| Brand | ABB |

| Type | Phase Modulation Processor Module |

| Processor | Dual-core 1.2 GHz |

| Memory (RAM) | 1 GB |

| Memory (Flash) | 512 MB |

| Control Execution Speed | 0.1 ms (Boolean operations) |

| Communication Ports | 2× Ethernet, Digital I/O |

| Digital I/O Channels | 32 (32 inputs, 32 outputs) |

| Operating Voltage | 24 V DC signals supported |

| Weight | Approximately 2.5 kg |

| Operating Temperature | Industrial standard (Typically -20°C to +70°C) |

| Mounting | Panel or rack mount |

Related Modules or Compatible Units

PPC903AE101 – A related phase modulation and signal processing module providing enhanced network communication features.

PM866 – ABB’s high-performance processor used in concert for distributed control applications.

PPD113B01-10-150000 – A control processor module compatible for integrated automation control tasks.

UAD149 – Fault detection module that complements PPC902AE101 in communication and control networks.

CI854 – Communication interface module enabling integration with industrial communication protocols.

TEF4-ON – A support module for excitation and phase control in complex system environments.

Installation Notes & Maintenance Best Practices

During installation of the ABB PPC902AE101 3BHE010751R0101, ensure the module is mounted in a well-ventilated rack or control panel to facilitate heat dissipation and avoid thermal stress. Proper grounding and shielding are essential to maintain electrical noise immunity, especially in environments with high electromagnetic interference. Cables for Ethernet and digital I/O should be carefully routed to prevent signal degradation.

Maintenance should include periodic inspection of connectors and cooling systems, as well as functional testing of communication ports for signal integrity. Applying ABB’s firmware and software updates regularly will help keep the module compatible with evolving network protocols and security requirements. Utilizing ABB’s diagnostic tools assists in detecting anomalies early, allowing preventive maintenance to sustain high reliability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626