Description

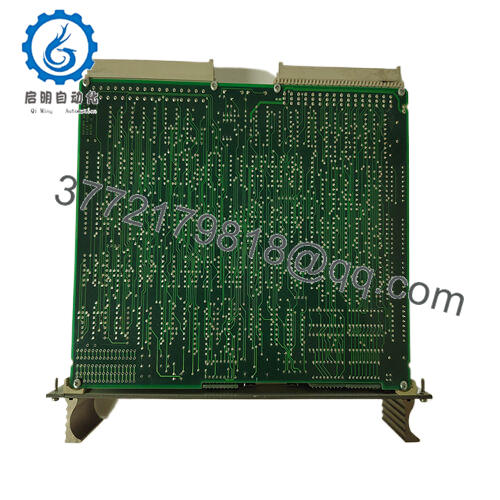

The ABB PMA323BE HIE300308R1 control board plays a crucial role as the central nervous system in industrial automation systems, especially in the field of motor control, playing an irreplaceable role. It is designed specifically for ABB’s specific series of motor control equipment, and can work closely with various components in the motor drive system to achieve precise monitoring and efficient regulation of the motor’s operating status.

PMA323BE HIE300308R1

This control board adopts advanced microprocessor technology and has powerful data processing capabilities. It can quickly and accurately analyze feedback signals from sensors and generate corresponding control instructions based on preset control strategies to ensure that the motor runs stably at the expected speed, torque, and direction. Its rich interface resources, including multiple digital input/output ports and analog signal interfaces, can easily connect various sensors, actuators, and other external devices, greatly expanding the system’s functionality and application scope. In terms of communication, it supports multiple standard communication protocols such as Modbus, Profibus, etc., which facilitates data exchange with the upper control system, enables remote monitoring and management, and makes the operation of the entire industrial automation system more intelligent and efficient.

PMA323BE HIE300308R1

Technical specifications:

Model Number PMA323BE HIE300308R1

Brand ABB

Type Control Board

Input Voltage 24V DC (±10%)

Processor Type High – performance microprocessor

Memory Capacity 512 KB Flash, 128 KB SRAM

I/O Ports 16 digital inputs, 12 digital outputs, 4 analog inputs, 2 analog outputs

Communication Protocols Modbus RTU, Profibus DP, Ethernet/IP (optional)

Operating Temp Range -20°C to +60°C

Storage Temp Range -40°C to +85°C

Humidity 5% – 95% RH, non – condensing

Protection Class IP20

Dimensions 150 mm x 100 mm x 30 mm

Weight 0.3 kg

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818

PMA323BE HIE300308R1

Main features and advantages:

Its excellent stability comes from carefully designed circuit architecture and high-quality electronic components, which can operate continuously and stably in complex electromagnetic interference environments and a wide temperature range, greatly reducing the risk of equipment downtime caused by control board failures and ensuring the continuity of the production process. In terms of control accuracy, this control board can achieve precise control of motor speed and torque, with deviations controlled within a very small range, meeting the high quality requirements of production processes. The fast response speed enables it to promptly respond to various dynamic changes during the operation of the motor, such as sudden load changes, effectively improving the operational performance and efficiency of the motor. In addition, the ease of integration and debugging significantly shortens the development cycle of new systems and the upgrade and transformation time of existing systems, reduces project implementation costs, and brings higher economic benefits to enterprises.

Application areas:

In the manufacturing industry, it is widely used for motor control in automated production lines, accurately coordinating the actions of various motors, ensuring efficient and stable operation of the production line, and improving the production quality and consistency of products;

In the power industry, the control of large motor equipment such as fans and pumps used in power plants ensures stable operation of the equipment under different working conditions, achieving energy conservation, emission reduction, and efficient utilization of power resources;

In the field of logistics and warehousing, control boards assist in the precise operation of motors in automated warehousing equipment, achieving fast and accurate handling and storage of goods, and improving the efficiency of warehousing and logistics.

Related products:

ABB PMA322BE HIE300307R1: It has relatively basic functions and is suitable for small industrial projects with less complex control function requirements and limited budget.

ABB PMA324BE HIE300309R1: Enhanced in processor performance, memory capacity, or communication capabilities, suitable for complex industrial scenarios that require higher control board performance, large amounts of data processing, or high-speed communication.

ABB PMA323CE HIE300308R2: Optimized in terms of protection level or anti-interference ability, it is more suitable for use in harsh industrial environments, such as factory workshops with strong electromagnetic interference, high humidity, and high dust.

ABB PMA323BE-X HIE300308R1X: a customized version for specific industries or application scenarios, adding some special functional modules or interfaces to meet the unique needs of specific fields.

ABB PMA321BE HIEE300306R1: With simple functions and relatively low prices, it can be used as an entry-level control board for some basic industrial equipment that does not require high motor control accuracy and functionality.

Installation and maintenance:

Before installing the ABB PMA323BE HIE300308R1 control board, engineers need to carefully check whether the input power supply voltage is within the range of 24V DC (± 10%) to ensure the stability and reliability of the power supply and avoid damaging the control board due to abnormal voltage. At the same time, it is necessary to check whether the installation space meets the size requirements of 150 mm x 100 mm x 30 mm for the equipment, and ensure that the installation location has good ventilation and heat dissipation conditions to prevent the control board from overheating during operation. In addition, it is necessary to confirm whether the interface of the control board matches the specifications and types of the connecting cables to ensure the stability and correctness of the electrical connection.

In daily maintenance, regularly check the status indicator lights on the control board to determine whether the equipment is running normally based on the status of the indicator lights; Check if the wiring terminals are loose to prevent poor contact from causing abnormal signal transmission or control command failure. Perform functional tests on the control board at regular intervals to verify its control accuracy, response speed, and communication function for the motor. Once an abnormality is detected, the detailed user manual and fault diagnosis guide provided by ABB can be used to quickly locate and solve the problem.

Other ABB product models:

ABB 206-00212

ABB 216AB61 HESG324013R101

ABB 216AB61 HESG324013R0101

ABB 216DB61 HESG324063R100/H

ABB 216DB61 HESG324063R100/H

ABB 216DB61 HESG324063R0100

ABB 216EA61B HESG448230R1/G

ABB 216EA62

ABB 216EA62

ABB 216EA62

ABB 216EA62 1MRB150083R1/F

ABB 216MB66 HESG324510M1

ABB 216NG62A HESG441634R1/K HESG216876

ABB 216NG63A HESG441635R1 HESG216879/K

ABB 216V62a HESG324442R13/B

ABB 216VC62a HESG324442R112/F

ABB 216VC62a HESG324442R112/F

ABB 216VC62a HESG324442R112/F

ABB 216VC62a HESG324442R13/B

ABB 216VC62A HESG324442R112/F

ABB 216VC62A HESG324442R13

ABB 216VC62A HESG324442R13

ABB 216VC62A HESG324442R13

ABB 216VC62a/P1000 HESG324442R112

ABB 2CSG299893R4052

ABB 2CSG299893R4052

ABB 2UBA00004416R0007

ABB 3AUA0000036521

ABB 3AUA0000110430

ABB 3BDS005799R1 PM665

ABB 3BHB003688R0101

ABB 3BHB003688R0101

ABB 3BHB003689

ABB 3BHB003689

ABB 3BHB003689

ABB 3BHB003689 3BHB003688R0101

ABB 3BHB005243R0105

ABB 3BHB005243R0106 KUC755AE106

ABB 3BHB005243R0117

ABB 3BHB005245R0101

ABB 3BHB005922R0001

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626