Description

Real-World Use & Application Scenarios

The ABB PM825 3BSE010796R1 is a robust, high-performance processor module designed for applications where reliable control and operational stability are critical. Its primary use is in process automation environments such as oil and gas, power plants, water treatment facilities, and chemical industries. These sectors demand uninterrupted, precise regulation of key process parameters including flow, temperature, pressure, and safety interlocks. Applicable in control systems like ABB’s Advant OCS and AC 800M platforms, this processor module excels in managing complex industrial operations by enabling real-time control and fault-tolerant communication across distributed control architecture.

This product thrives in industrial automation where scalability, redundancy, and integration flexibility are mandatory. Engineers specify the ABB PM825 3BSE010796R1 for its ability to operate reliably under harsh industrial conditions, supporting seamless connection to field devices and higher-level supervisory systems. It tackles challenges such as high availability, multi-protocol compatibility, and accurate data processing, making it an essential component in large-scale and safety-critical automation projects. Its deployment helps improve plant productivity, reduce downtime, and maintain process compliance under diverse operational stresses.

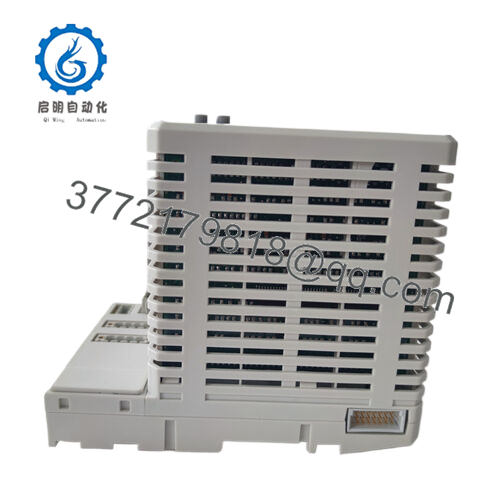

PM825 3BSE010796R1

PM825 3BSE010796R1

Product Introduction & Positioning

The ABB PM825 3BSE010796R1 is a processor unit within ABB’s esteemed AC 800M and Advant OCS distributed control systems, serving as the core controller that executes control logic and manages communication between subsystems and operator interfaces. It acts as the central processing hub, facilitating efficient and coordinated data flow in complex automation systems.

This module fits into modular control architectures, allowing integration with ABB’s extensive range of I/O modules and communication interfaces. Its design supports redundant configurations and fault-tolerant operation, which are critical for plants that require high availability. The processor runs on a robust platform optimized for industrial performance and offers support for protocols including PROFIBUS, Modbus TCP, and FOUNDATION Fieldbus, ensuring adaptability within diverse plant networks. Engineers benefit from its straightforward mounting on standard DIN rails and its compatibility with ABB’s system 800xA software environment, making the ABB PM825 3BSE010796R1 a versatile processing solution.

Key Technical Features & Functional Benefits

The ABB PM825 3BSE010796R1 offers a compact yet powerful processing solution with an industrial-grade processor that delivers dependable control performance for both continuous and batch processes. It integrates two RJ45 Ethernet ports for reliable network communication, facilitating redundancy and ensuring system uptime in demanding applications. The inclusion of multiple serial ports supports configuration tools and external device connectivity, enabling comprehensive system integration.

Designed for industrial environments, the PM825 can endure operational temperatures typically ranging from 0 to +60 degrees Celsius and meets an IP20 environmental protection class, offering resistance against dust ingress and electromagnetic interference. The unit’s modular design and flexible mounting options simplify system expansions and maintenance. Its compatibility with ABB’s CEX-Bus and ModuleBus communication buses allows for extensive I/O connectivity and increases system flexibility.

This processor unit supports ABB’s proven fault-diagnosis mechanisms, which help minimize downtime by facilitating rapid troubleshooting. Its memory architecture ensures sufficient capacity for large-scale control programs, and the system supports safe operation certifications, enhancing confidence in its use in safety-critical settings. The ABB PM825 3BSE010796R1 thus provides a reliable foundation for plant-wide automation with a focus on performance, compatibility, and long-term serviceability.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | ABB PM825 3BSE010796R1 |

| Brand | ABB |

| Product Type | Processor Unit / Controller Module |

| Processor Frequency | Industrial grade CPU (specific MHz not specified) |

| Power Supply | 24 V DC |

| Operating Temperature | 0°C to +60°C |

| Mounting | DIN rail |

| Dimensions | Approx. 225 mm (Length) x 135 mm (Width) x 108 mm (Height) |

| Weight | Approx. 1.0 kg |

| Interfaces | 2 x Ethernet ports, Multiple serial ports |

| Environmental Protection | IP20 |

| Communication Bus Support | CEX-Bus, ModuleBus |

| Certifications | IEC, CE, UL standards (specific certification numbers not specified) |

Related Modules or Compatible Units

ABB PM861 – A CPU processor unit with basic control functions within the AC 800M family.

ABB PM862 – A robust processor supporting expanded memory and redundancy features.

ABB PM866 – A high-end CPU module with advanced processing capabilities for demanding applications.

CI854A PROFIBUS Interface – Connects ABB controllers to PROFIBUS fieldbus networks.

CI860 FOUNDATION Fieldbus Interface – Enables integration of FOUNDATION Fieldbus devices.

S800 I/O Modules – Provide analog and digital I/O support for ABB controllers.

TU516 Hot Swap Terminal Unit – Allows for changing I/O modules without operational downtime.

BC810/BC820 CEX-Bus Interconnection Units – Facilitate communication bus segmentation to increase system availability.

Installation Notes & Maintenance Best Practices

Installation of the ABB PM825 3BSE010796R1 requires appropriate DIN rail provision and sufficient clearance within control cabinets to ensure airflow and heat dissipation. Proper cable management for dual Ethernet ports and serial interfaces is necessary to maintain communication integrity and simplify troubleshooting. Ground connections must comply with industrial standards to avoid noise interference which could affect signal quality.

Routine maintenance should incorporate visual system checks for dust accumulation, secure wiring, and module status indication lights. ABB’s diagnostic software tools offer valuable insights for preventive maintenance, enabling early fault detection. Firmware and control program updates should be managed systematically to incorporate the latest enhancements and security patches. Maintaining documentation and backup configurations are critical for minimizing recovery time during unexpected outages.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626