Description

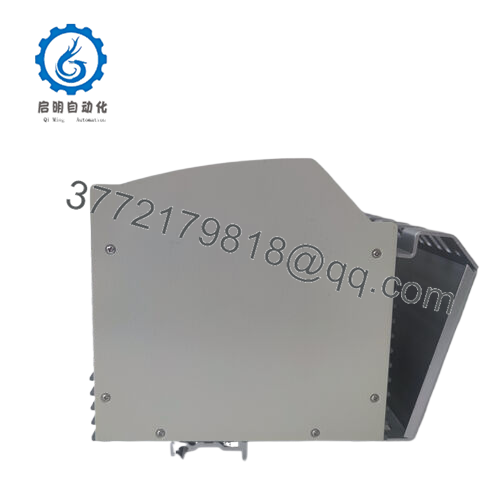

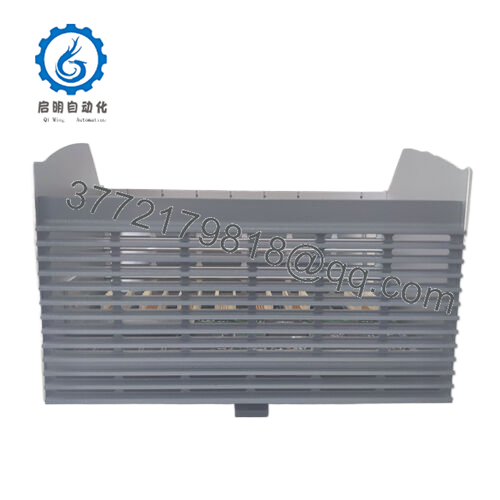

Product Model: ABB PM802F

Product Brand: ABB

Product Series: PM Series

Product Features:

- High-precision monitoring for industrial and commercial power systems

- Seamless integration with ABB automation controllers and SCADA systems

- Real-time data acquisition with historical logging and analytics

- Robust design ensuring reliable performance in harsh environments

Applications & Industry Context

The ABB PM802F is a key component in modern energy management systems across industries requiring high reliability and precision. Manufacturing facilities, water treatment plants, data centers, and large commercial buildings all benefit from the module’s ability to accurately monitor energy consumption, detect inefficiencies, and prevent power-related downtime.

In manufacturing, unpredictable machine loads and complex three-phase networks can make energy tracking challenging. Installing the ABB PM802F allows engineers to monitor voltage, current, power factor, and harmonics in real-time, enabling proactive adjustments to prevent overloading and optimize operational efficiency. For commercial facilities, accurate measurement supports energy audits, cost allocation, and compliance with environmental and efficiency regulations.

Operators often report that incorporating the ABB PM802F into control panels significantly improves visibility into energy flows, helping teams identify anomalies, plan maintenance, and reduce energy costs. Whether in industrial, commercial, or utility environments, this module provides reliable insights for energy-conscious decision-making and operational optimization.

Product Role & System Fit

Functioning as a high-accuracy power meter, the ABB PM802F is designed to integrate seamlessly into ABB’s automation and control ecosystem. Its role is to measure and report key electrical parameters, including active and reactive power, voltage, current, frequency, and power factor, providing actionable insights for energy management strategies.

The module’s versatility allows it to fit a variety of system architectures. It is compatible with ABB PLCs, motor control centers, and SCADA platforms, supporting multiple communication protocols for seamless integration. By combining ABB PM802F units across a facility, operators can build a comprehensive energy monitoring network that centralizes data, enhances analytics, and enables predictive maintenance.

Within the system, the ABB PM802F acts as both a monitoring device and a data source, enabling engineers and energy managers to make informed operational decisions. Its ability to relay precise real-time information supports optimized load distribution, preventive maintenance schedules, and strategic energy management initiatives.

Technical Features & Benefits

The ABB PM802F stands out for its high-precision energy measurement capabilities, capturing complex power metrics accurately under variable loads. This ensures reliable performance in industrial environments where machinery cycles and power fluctuations are common.

The module is built for durability, with resistance to electrical noise, temperature variation, and vibration, making it ideal for industrial panels and demanding operating conditions. Engineers note that ABB PM802F consistently delivers stable readings, reducing the need for frequent calibration or troubleshooting.

Real-time monitoring and historical logging capabilities make the module indispensable for energy audits and operational optimization. Data can be accessed locally via a backlit LCD or remotely through ABB’s SCADA-compatible software. This provides flexibility for operators to track energy usage trends and identify inefficiencies before they escalate.

Installation is user-friendly, with a compact design suitable for DIN rail or panel mounting. Communication options such as Modbus and Profibus enable easy integration into existing systems. The ABB PM802F combines precision, robustness, and connectivity, offering engineers a reliable solution for comprehensive energy management.

Technical Specifications Table

| Specification | Detail |

|---|---|

| Product Model | ABB PM802F |

| Measurement Type | Active/Reactive Power, Voltage, Current, Frequency |

| System Type | Three-phase |

| Accuracy Class | Class 0.5S |

| Display | LCD, backlit |

| Communication Protocols | Modbus RTU, Profibus, Ethernet (optional) |

| Voltage Rating | 100–500 V AC |

| Current Input | 1–5 A / 0.1–6 A |

| Operating Temperature | -10°C to 55°C |

| Mounting | DIN rail or panel |

| Power Supply | 100–240 V AC/DC |

| Dimensions | 96 × 96 × 70 mm |

ABB PM802F

ABB PM802F

Installation & Maintenance Insights

Installing the ABB PM802F is straightforward but requires careful attention to environmental conditions. Ensure the module is mounted in a stable, clean environment, avoiding excessive heat, dust, or moisture. Proper cable sizing and secure terminal connections are critical for accurate measurements.

Routine maintenance primarily involves verifying readings and checking communication lines. The module’s LCD interface and remote monitoring capabilities allow engineers to quickly identify anomalies or connectivity issues. Maintaining stable electrical conditions and avoiding unnecessary disconnections helps sustain long-term accuracy.

Field technicians often recommend annual verification of the module’s calibration, with more frequent checks in high-demand environments. Following ABB’s installation and maintenance guidelines ensures consistent performance and minimizes operational disruptions.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626