Description

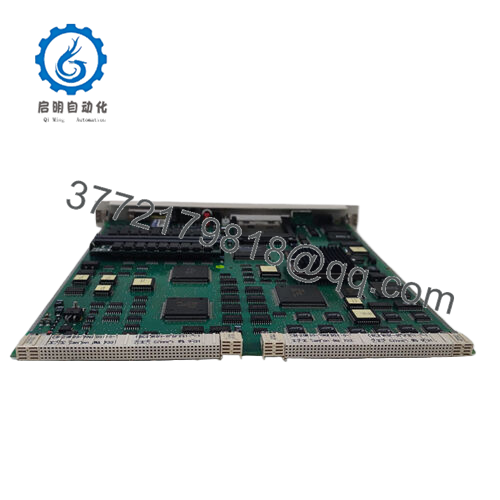

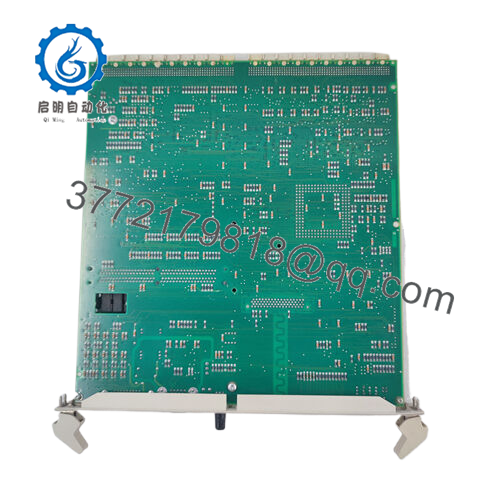

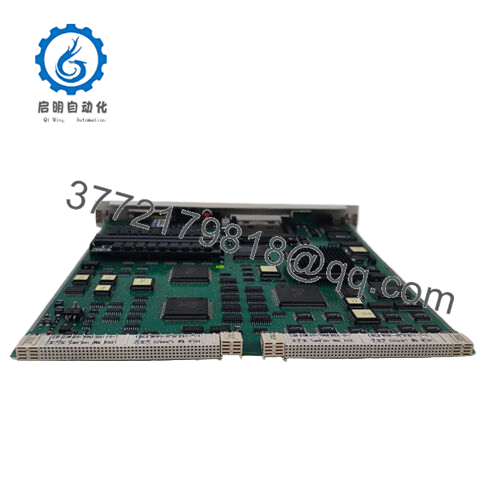

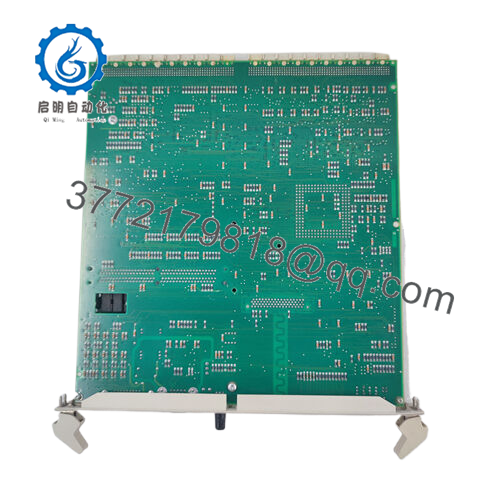

Product Model: ABB PM511V16 3BSE011181R1

Product Brand: ABB

Product Series: PM / AC400 / Advant OCS family

Product Features:

- Core processor module designed for ABB AC400 / Advant OCS systems

- 16 MB internal memory supporting control applications and diagnostics

- Rugged design suited for industrial environments (temperature, noise resistance)

- Compact form factor (274.5 × 270 × 27 mm) with modular mounting capability

Technical Specifications Table

| Specification | Detail |

|---|---|

| Product Model | ABB PM511V16 3BSE011181R1 |

| Type / Role | Processor / Central Control Module |

| Control Systems | ABB AC400, Advant OCS, Advant Controller 450 series |

| Memory | 16 MB internal |

| Dimensions (Depth × Width × Height) | 274.5 mm × 270 mm × 27 mm |

| Net Weight | ~ 0.8 kg |

| Input Power / Voltage | 24 VDC (approx. ~10 W consumption) |

| Communication Interfaces | RS-232, RS-485, Ethernet (10/100Base-T) |

| Processor / Speed | (As per published datasheet) – references mention 32 MHz in third-party listing |

| Operating Temperature | –10 °C to +55 °C (industrial rating) |

| Mounting | Modular rack / panel mount (fits Advant 450) |

| Compliance / Certifications | RoHS, industrial control system standards |

Product Role & System Fit

The ABB PM511V16 3BSE011181R1 is fundamentally a processor (central control) module intended for use within ABB’s AC400 and Advant OCS automation systems. In a typical setup, this module serves as the “brain” — executing control logic, coordinating I/O modules, managing diagnostics, and providing communication links to higher-level systems (SCADA, DCS, or operator consoles).

In many plants running the Advant OCS or Advant Controller 450 line, the PM511V16 slots into a modular rack or backplane architecture, interacting with digital I/O, analog I/O, communication modules, and optionally safety (PSD) systems. Because it carries 16 MB of internal memory, it can host substantial control logic and diagnostic code, while also maintaining logs or history as required by the process.

One daily observation from field engineers is that replacing or upgrading the central module often yields benefits well beyond raw processing — upgrading to PM511V16 (from older models) improves response time, fault recovery, and maintainability. In redundant setups, two PM511V16 units may share roles (active/standby) to ensure continuous operation, especially in critical industrial or petrochemical plants.

Because it is part of ABB’s legacy control ecosystem, the ABB PM511V16 3BSE011181R1 is compatible with numerous legacy and modern I/O modules, and can communicate via standard protocols (RS-232/485, Ethernet) to bridge older and newer systems.

Applications & Industry Context

In sectors where reliability, safety, and continuity are non-negotiable, the ABB PM511V16 3BSE011181R1 has a long track record. It appears in process plants (oil & gas, petrochemical, chemical), power generation facilities, water and wastewater treatment, and in industrial automation installations that demand both process control and safety linkage (PSD systems).

PM511V16 3BSE011181R1

PM511V16 3BSE011181R1

For example, in a chemical plant, the PM511V16 might orchestrate reactor control loops, adjust valve positions, monitor pressure sensors, and communicate with higher-level monitoring systems. Should a fault or unsafe condition arise, the module can hand over to a process shutdown (PSD) circuit to intervene, ensuring plant safety.

In power plants, it may control auxiliary systems — e.g. boiler feedwater, cooling systems, turbine support systems — where consistent reliability is essential. The PM511V16’s robustness against electrical noise, combined with its modular architecture, helps it survive in electrically harsh environments like generator rooms or switchyards.

In retrofits or expansions, the ability to slot in a well-supported module such as ABB PM511V16 3BSE011181R1 gives system integrators a reliable path to modernizing legacy systems without full replacement. Field engineers often remark that swapping out aging central modules with PM511V16 brings improved diagnostics, smoother commissioning, and lower risk during handover.

Technical Features & Benefits

One of the strongest features of the ABB PM511V16 3BSE011181R1 is its memory headroom: the 16 MB internal memory enables not only complex control logic but also space for diagnostics, logging, and redundancy routines. In practice, this provides flexibility so that control engineers can embed more advanced routines, filter flapping signals, or store historical fault traces.

The module’s communication versatility (with RS-232 / RS-485 serial links and Ethernet) allows it to act as a gateway, coordinating data between legacy I/O racks and modern supervisory systems. This flexibility is especially valuable in plants evolving gradually — the module becomes a bridge between old and new subsystems.

Robustness is another headline benefit. The ABB PM511V16 3BSE011181R1 is built to withstand industrial stresses: temperature swings, electromagnetic interference, vibration, and occasional surges. The slim 27 mm profile (depth 274.5 mm) helps it fit cleanly into dense racks without sacrificing stability or cooling.

Another feature is modular diagnostics. The module can monitor and report faults, log error history, and support hot swap (where allowed) of adjacent I/O modules—minimizing downtime. Engineers in the field often appreciate that such diagnostic feedback allows remote root-cause analysis instead of blind manual debugging.

From an installation perspective, the ABB PM511V16 is fairly plug-and-play in the ABB ecosystem. It comes with version compatibility for many Advant OCS and AC400 distributions, so integrating with existing system configs is smoother. One practical tip: always run firmware version checks and backups before module swaps — mismatched firmware is a common source of issues.

All told, the PM511V16 balances processing headroom, industrial resilience, and ecosystem compatibility. It is a core building block for long-lived control systems in demanding environments.

Installation & Maintenance Insights

Installing ABB PM511V16 3BSE011181R1 requires careful attention to its mechanical and electrical environment. First, ensure the rack or backplane is clean, properly grounded, and free from excessive heat or dust. Given its slim depth and width, make clearance allowances for airflow and cabling.

Cabling is crucial: use shielded twisted pair for RS-485, maintain separation from power cables, and secure connectors firmly (but not overtight). In many field setups, communication lines may pass through conduit or cable trays — maintain bend radii and avoid sharp turns or strain points.

Since the module can communicate over Ethernet, ensure isolated ground referencing to prevent ground loops. If redundancy is used, label and document active/standby channels carefully, and test failover switching before putting the system into production.

For maintenance, periodic (e.g. annual) verification is advisable: check diagnostics logs, validate communication links, and confirm that firmware is current. Many users schedule preventive maintenance windows to back up configuration memory, monitor error counters, and inspect connector integrity. In high-stress environments (vibration, thermal cycling), more frequent inspections may be justified.

An anecdote: in one refinery upgrade, an engineer discovered a marginal connector pin due to vibration; replacing it early prevented intermittent communication failures months later. The diagnostics in PM511V16 help catch such subtle issues before they escalate.

Overall, care in installation (grounding, shielding, labeling) and a disciplined maintenance regimen make the ABB PM511V16 3BSE011181R1 a dependable long-term asset.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626